When seeking to decarbonize their operations, scale up new processes or implement other consequential changes, chemical companies often enter unfamiliar territory. In some cases, the new operations and design considerations they encounter may be unlike any they have ever experienced. Likewise, technology licensors focused on their core technology may not fully understand how their solution will be integrated into an existing operation.

Information voids and experience gaps are not the only early warning signs that a unique or emerging technology project may be headed off track. A project team that finds itself changing a project’s priorities and objectives while its scope is still being defined may also be on an undesirable path, putting the project at risk of scope creep. Unidentified and unmitigated risks can derail a project along the way as well, as can uncertainty regarding a project’s economic or technical feasibility.

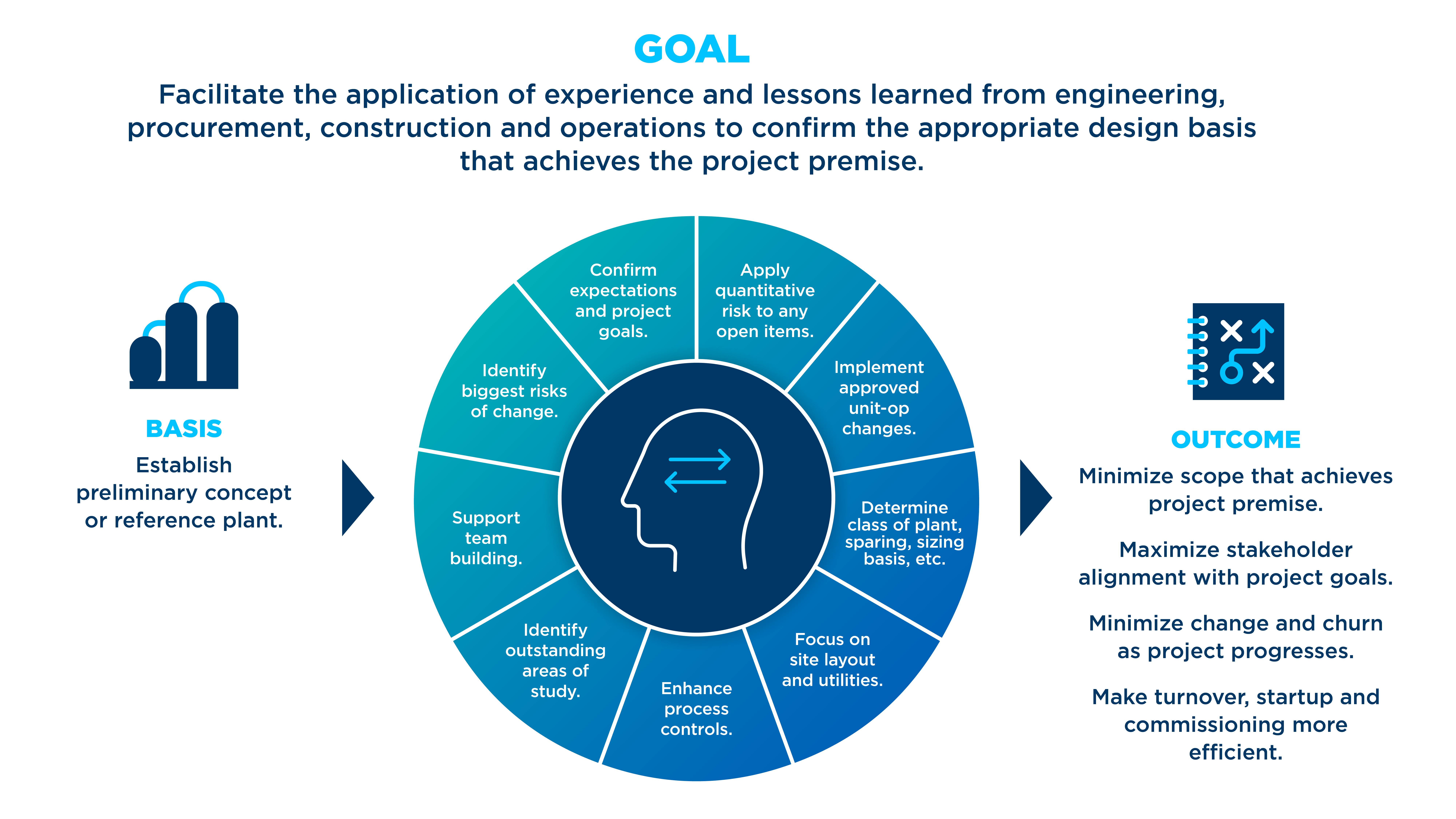

An engineering and construction partner that understands these and other nuances associated with technology integration can help make projects successful. Using a structured knowledge transfer process can help teams identify and understand the knowns and unknowns at an early stage in a project, which can be instrumental in minimizing change and churn as the project advances through a gated work process.

While a knowledge transfer process can be used before the start of any phase on virtually any project, it is ideally suited for front-end planning on projects that contain elements known to cause indecision. These can include first-time and unique projects, as well as projects that involve scaling up processes or transferring technology to different countries. Knowledge transfer processes also can be beneficial for advanced plastic or battery recycling projects that involve mixed plastics or great metallurgical variety, as well as projects with under-defined heat and material balances, unique flowsheets, solids-handling issues or other factors that add to a project’s complexity or uniqueness.