The term “smart building” has always been subjective. A smart building is generally understood to be one outfitted with systems, sensors and devices that allow some level of automation and remote control of systems and equipment. However, it is possible to have a smart building that isn’t very efficient.

Now, we’re in a new era — on a journey from smart to smarter buildings, facilities and even entire campuses. With the smart building era now about 20 years old, the transition to the next era of smarter facilities and campuses is being defined by objective, quantifiable metrics aimed at demonstrating progress toward today’s new imperatives of greater energy efficiency, lower operating costs and a more flexible, safer and healthier work environment with occupant comfort in mind.

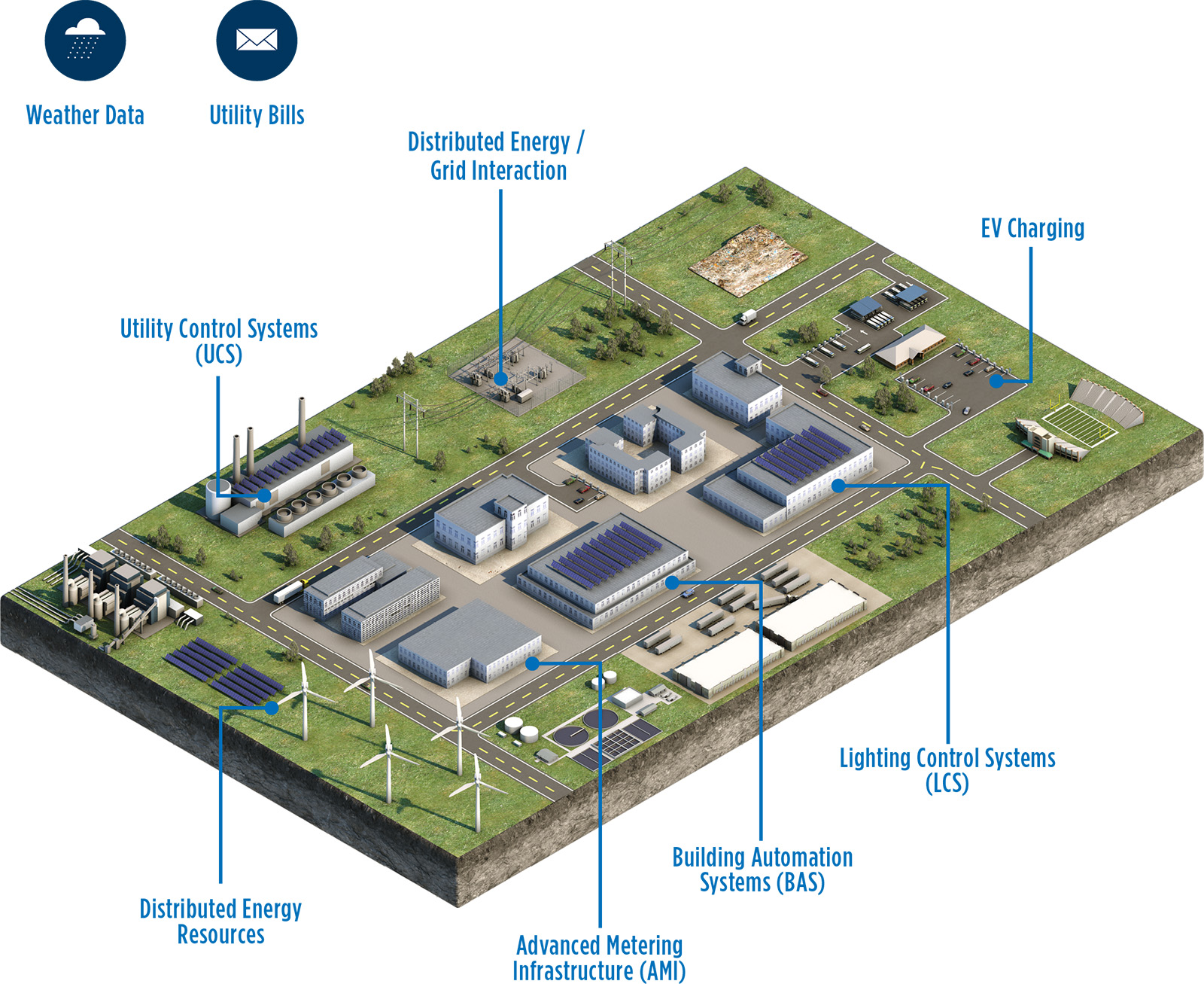

Smarter facilities are enabled by more sophisticated technologies like the Niagara Framework — a proven system that is widely deployed in many buildings to help achieve the vision of making vital equipment and applications smarter. Niagara enables diverse devices and equipment to be connected, normalized and integrated so they become interoperable in a common environment and on multiple embedded platforms.

Lynxspring, a provider of building controls hardware and open-source software, is another contributor to this movement. Lynxspring provides a number of technology solutions to meet many challenges and offers a single, scalable and extensible platform that allows facility operators to achieve greater levels of efficiency, safety and peak performance. For smarter facilities, Lynxspring has a line of digital controllers that can be installed with plug-in capability, allowing operators to seamlessly control, manage and monitor equipment and systems.

The technology is only half the story, however. The entire vision can be optimized further through the commissioning discipline. Commissioning provides the human insight and expertise needed to understand whether the data being gathered, compiled and reported is accurate and consistent with the rules set by monitoring systems. This verification process also is important to be sure that applicable codes and standards are being met.

Emerging disciplines include monitoring-based commissioning (MBCx) and the evolution of retro-commissioning (RCx) to new practices and approaches. MBCx is an ongoing program that relies on setting up data aggregation and monitoring systems to give operators the visibility to see how their systems are performing in real time. An RCx program measures and analyzes the performance of equipment and systems after they have been operating for a certain number of years.