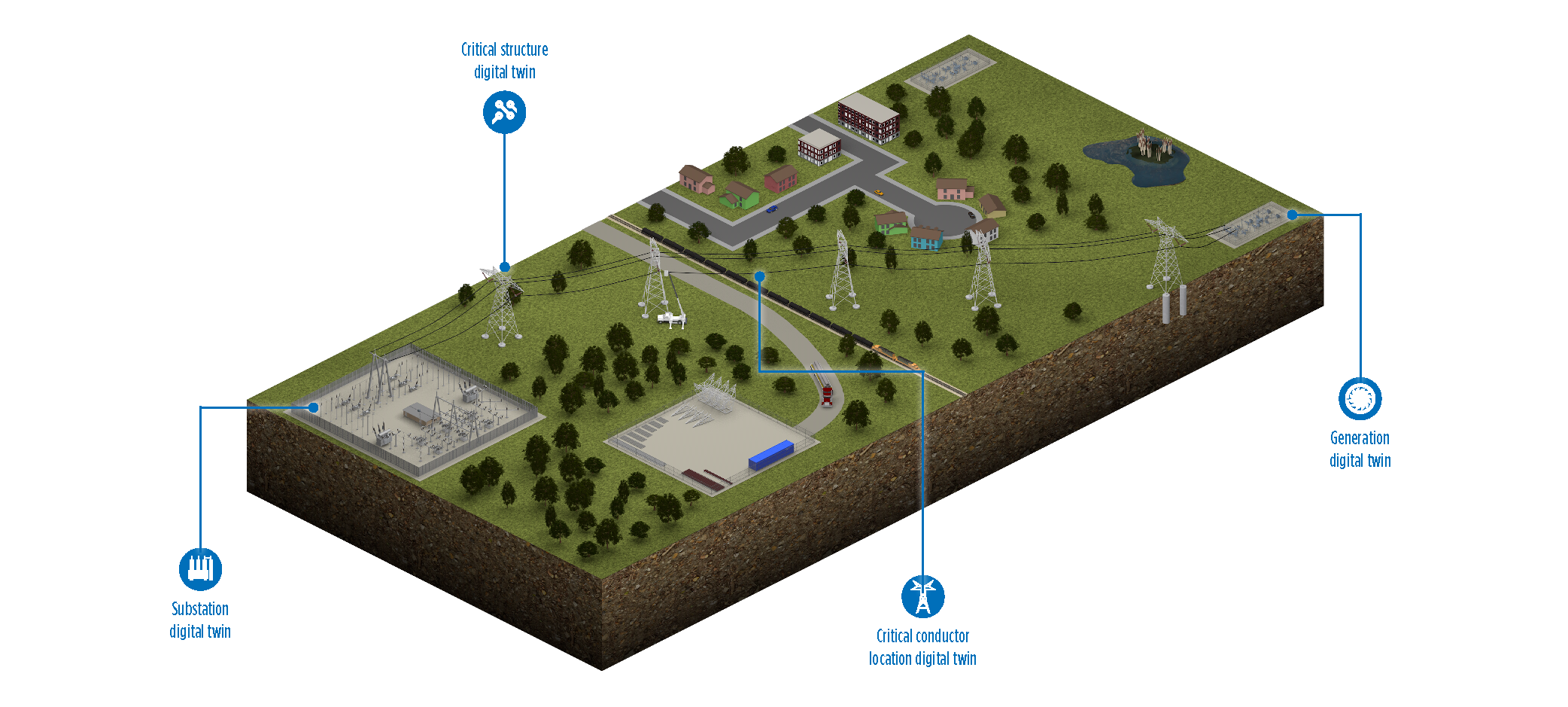

A digital twin is a virtual representation of an object or system that spans its life cycle and is updated using real-time field data. Since its development more than two decades ago, digital twin technology has supported the manufacturing, aerospace, automotive and power generation industries. It also has applications in transmission line design.

For example, standard practice calls for a line simulation under various weather conditions during transmission line design and analysis. Engineers use the results of these simulations to study structure and conductor behavior. Throughout a line’s service life, utilities conduct regular inspections and maintenance activities to identify safety concerns or structural issues.

Creating a digital twin goes beyond this standard simulation. Rather than waiting for an inspection to identify dangerous conditions, a digital twin monitors and communicates structure condition, conductor clearances and other critical information in real time. Advance knowledge of impending failures enables utilities to prepare for and prevent them, which can be especially valuable during storms and other extreme weather events.

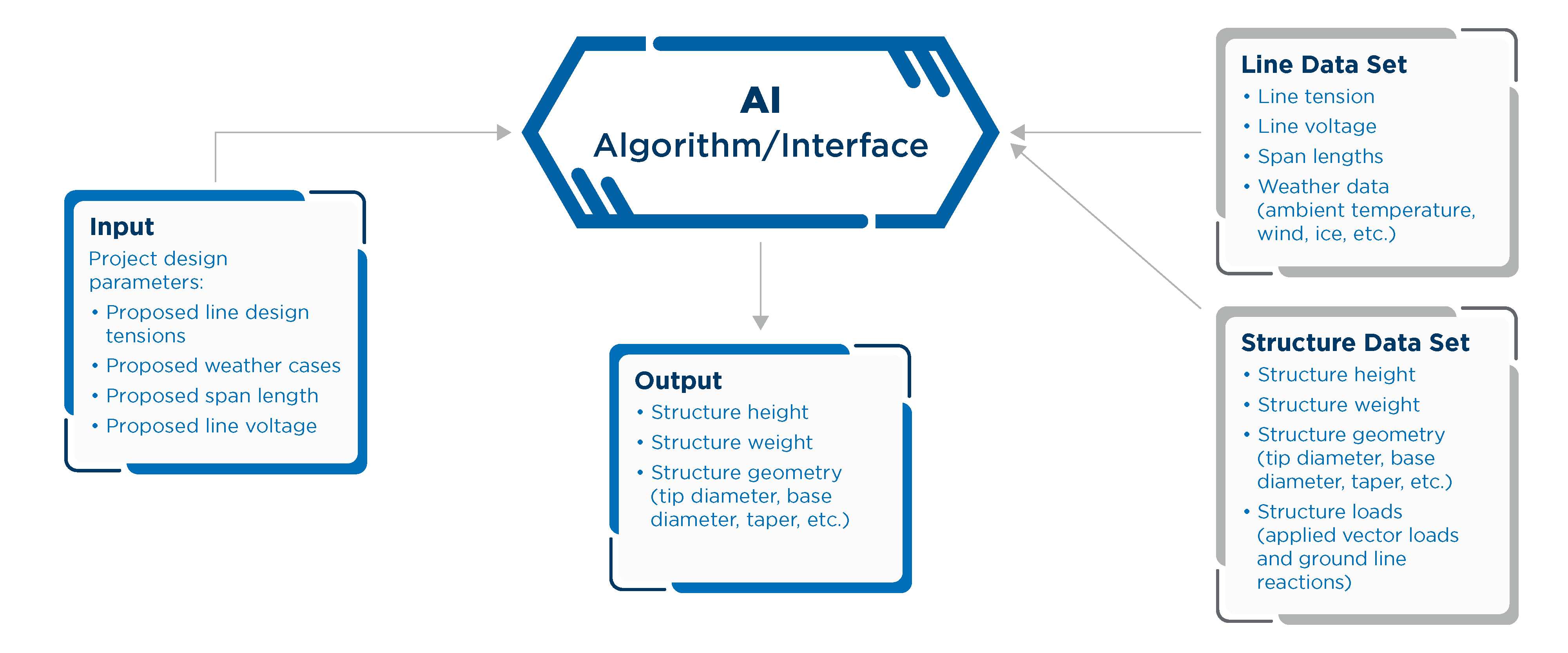

When coupled with AI algorithms and historical data, a digital twin is capable of scheduling predictive maintenance activities as well. Because lines are monitored in real time, utilities can more easily budget and allocate funds for the most critical projects.

Utilities can choose from four different types of digital twins: component twins, asset twins, system twins and process twins. Each has a different purpose. How digital twins are applied in a transmission line application depends on a utility’s end goals.

For example, a utility that wants a twin created for a single dead-end clamp or a single davit arm would choose a component twin. If it wished to replicate how a conductor and insulator interact, the utility would develop an asset twin. System twins and process twins — the optimal digital twins for transmission line applications — enable utilities to study their entire transmission system. By revealing how the complete system works together, these digital twins help utilities understand overall efficiency and effectiveness.

Bentley Systems, OpenAI, JetBrains, Tabnine and IBM are among the technology companies developing AI and digital twin technologies using AI, Internet of Things (IoT) and data analytics. These systems consist of an open, connected data environment (CDE) that runs digital workflows. They can execute user-established criteria, run scenarios and predict outcomes related to the performance and maintenance of physical assets.