The number of devices and use cases for construction technology continues to expand. Existing technologies allow project managers to track workflow and improve efficiency, discover and address safety violations, and increase security to reduce loss and waste. However, all of these technologies require a reliable network or data connection to update applications, feed data for monitoring systems and receive updates themselves.

Previously, there were two common solutions. An information technology (IT) team could set up a network that would meet the demands of the specific construction site, or the company could find a workaround, like placing a consumer wireless router in the construction trailer. The first option, while robust, is typically expensive and time-consuming. The second, while cost-effective, is rarely able to meet the demands of today’s connected world. Fortunately, mesh networks can now provide a more effective solution.

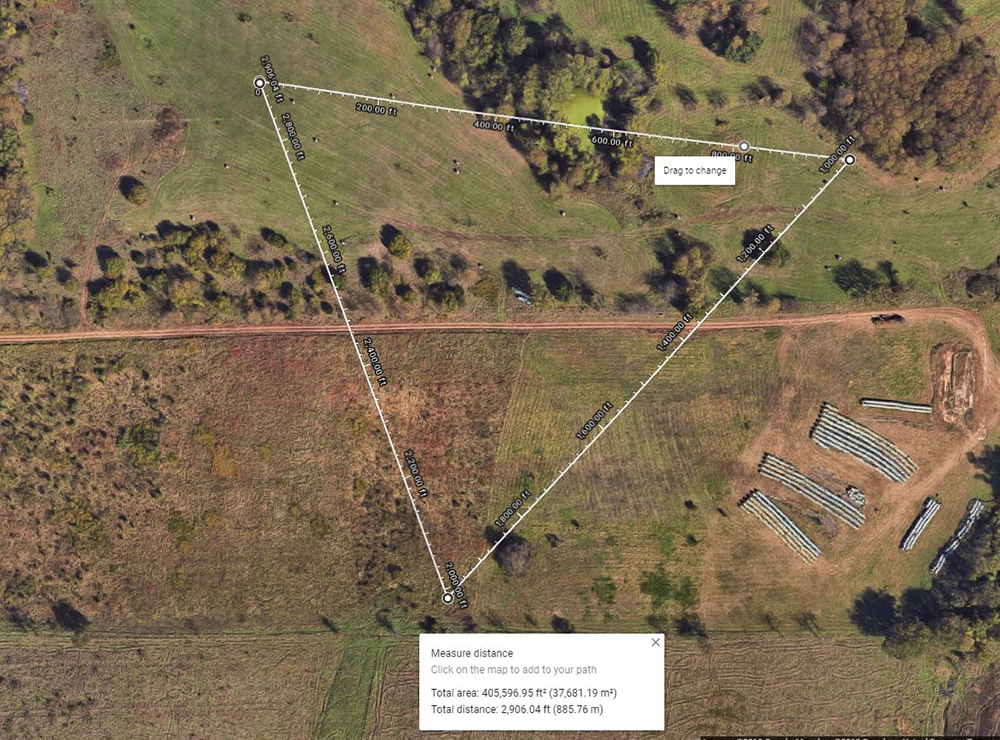

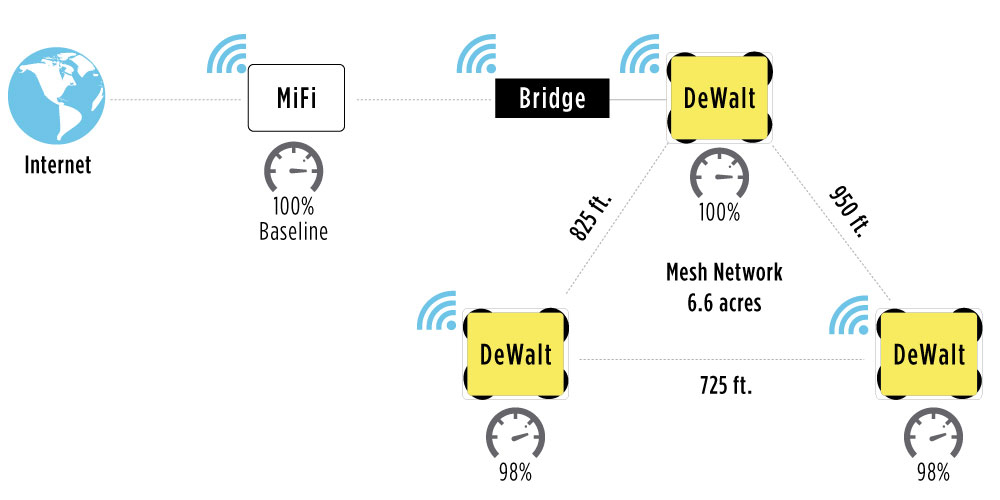

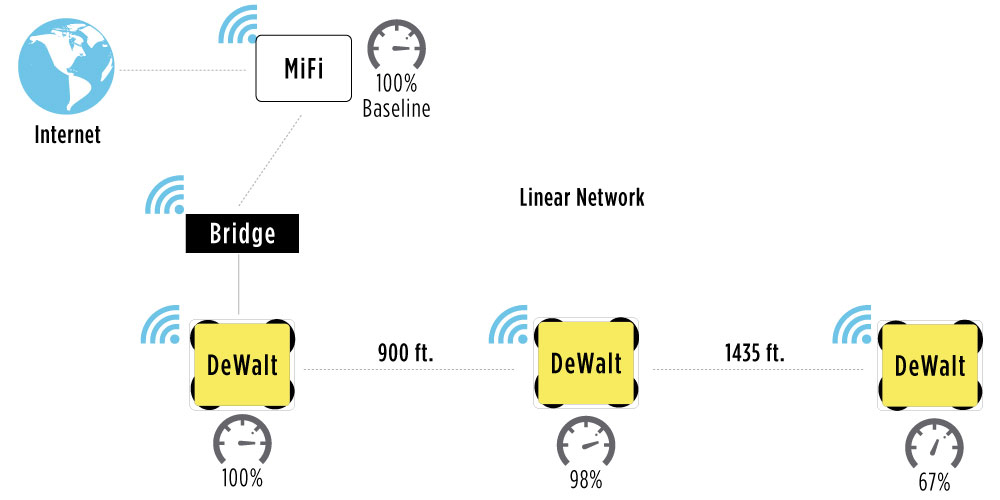

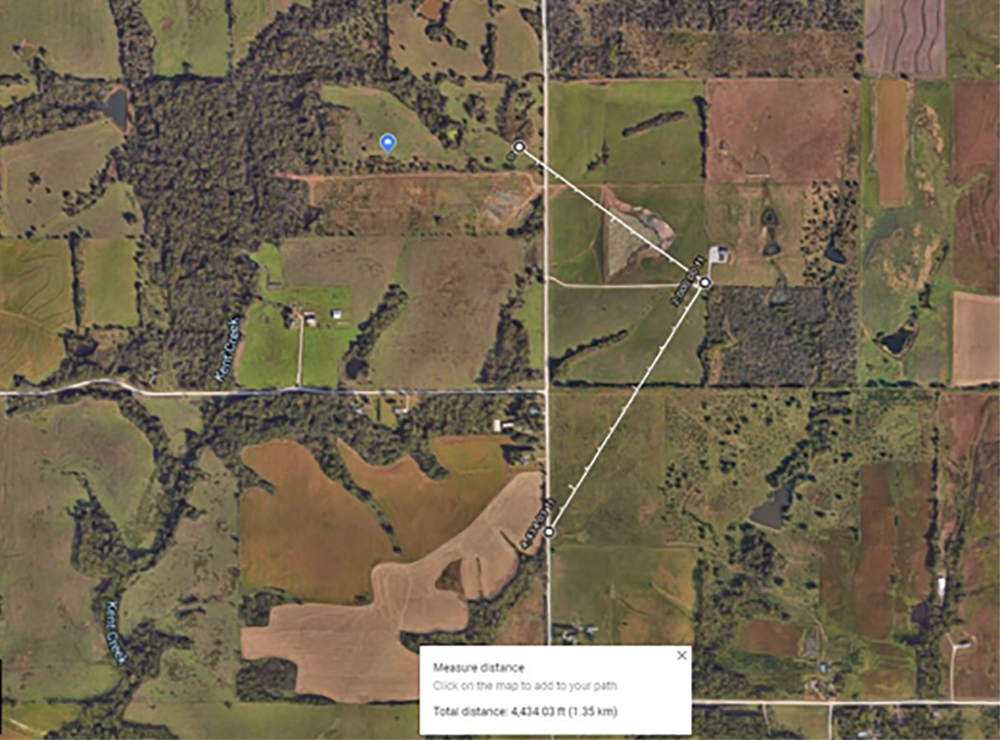

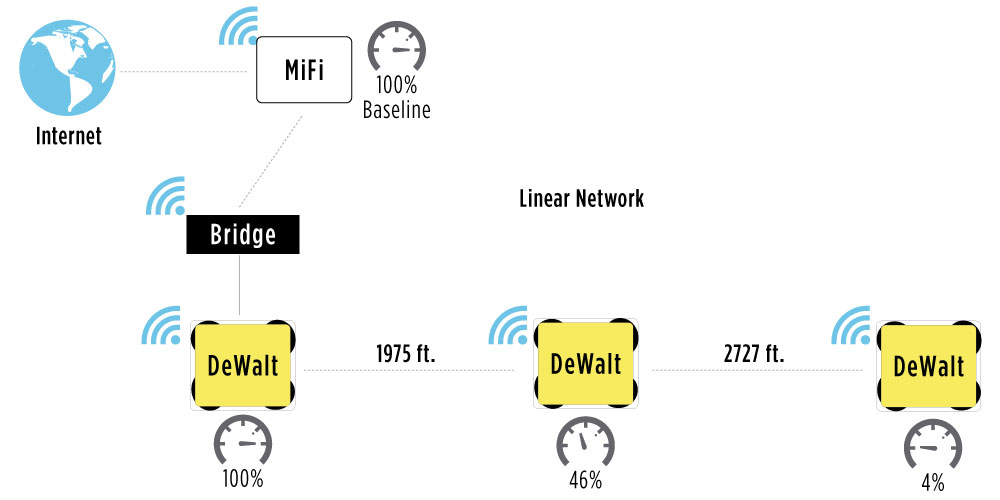

Mesh network technology isn’t new, but it has recently become robust and accessible to every level of construction. To determine the practical limits of wireless mesh networks, we conducted several tests simulating familiar construction environments. The results indicate that although autonomous excavation and real-time remote control will have to wait for 5G networks, construction companies can use mesh networks to begin capitalizing on many other technologies right away.