THE EPC ADVANTAGE

For terminal projects, tanks are a critical path item. However, consideration and strategy for the balance of terminal project scope help realize a safe, efficient terminal facility that meets operating goals.

Focusing on only the tanks and partnering with a tank fabricator to lead a terminal project demands that operators must make terminal decisions around a predetermined tank solution. This approach can greatly impact project scope and feasibility and increase unnecessary risk, cost and project time frame.

EPC services use proven processes, in-house knowledge and experience in available technologies to meet terminal project objectives with less risk and optimized operability. This approach offers a holistic view of the overall project, rather than a perspective solely focused on the tank. For terminal owners and operators, working with an EPC team offers considerable advantages.

SMARTER TERMINAL DESIGN

An upfront understanding of a terminal site and the available space for terminal expansion projects means greater options for asset and equipment decisions. Instead of designing a project around a predetermined tank solution, an EPC partner will evaluate tank options and site constraints based on working capacity and spacing requirements to develop the right option to meet the operational goals.

A comprehensive evaluation of site, codes and regulations reveals the optimal tank and equipment options around which a project will be developed. For example, if acreage isn’t available, owners can expect an EPC partner to offer alternatives for smaller diameter tanks, higher shell heights and hydraulics to meet requirements. Additionally, properly evaluating the processing needs in concert with the storage for natural gas liquids (NGLs) can save significant capital and maintenance costs compared to standard or prefabricated process units.

With a thorough understanding of available tank systems and technologies, operators can evaluate options and control cost at the front end, rather than making decisions to accommodate a prepackaged tank solution.

SITE OPTIMIZATION

Every proposed project site requires a critical and upfront evaluation of its potential challenges and design considerations. In addition to evaluating available transportation infrastructure to support a terminal, owners must examine regulatory and code requirements along with actual physical site features and limitations.

EPC services include extensive and careful initial site assessment to help identify how the balance of the site will evolve, over and above identified tank locations. Wetlands and flood plain review, restricted space and land grading, and environmental review are just some of the comprehensive evaluations that occur at a project outset to optimize a site and control cost.

Code requirements determine tank spacing and sizing to see that the volume of storage is met while efforts needed to prepare the site are minimized. Avoiding a one-size-fits-all tank solution allows owners the flexibility to get the most out of a site while achieving budget and schedule goals with reduced piping runs, electrical lines and wasteful terminal infrastructure.

STRATEGIC ENVIRONMENTAL COMPLIANCE

Avoiding a predefined tank solution gives owners the flexibility to address environmental regulations and code restrictions before the detailed design stage. This helps operators realize front-end cost savings that also align with environmental requirements.

Terminal projects that must secure a specific environmental permit, such as an air permit, are identified upfront. Any requirement that will affect tank design, type and technology — a geodesic dome or internal floaters, cooling, pressurization or gas blanketing — are evaluated and incorporated into the scope to help shape the entire project execution. Alternatively, products and compositions can be evaluated to consider blending or other scenarios that can minimize costs.

Unlike tank fabricators offering a standard package, EPC services provide extensive in-house engineering capabilities to design what is needed for the site and help determine the right technology for the project. Evaluation of environmental restrictions, setback requirements, land optimization and balance of site at the conceptual design phase helps meet project objectives that a standard, predefined tank package cannot accommodate.

COMPETITIVE SOURCING

Owners can expect an EPC partner to competitively bid all tanks, equipment and needed assets after initial scoping and evaluation defines project requirements. Tanks are often the bulk of any terminal project; therefore, operators benefit from EPC partnerships where tank brand and fabricator purchases are unbiased. Through competitive bidding, owners have increased options and potential savings, even for schedule-driven projects.

Since tanks represent the highest investment cost of a terminal, it is beneficial for the tank package to be competitively bid with considerations of all aspects of safety, design, schedule and constructability. This offers the owner significant cost savings.

Partnering with a tank fabricator or erector limits a terminal project to a sole source. While that can be an effective strategy for well-defined, less complex projects, it introduces risk for terminal projects that inherently have many elements and, by default, potential complications.

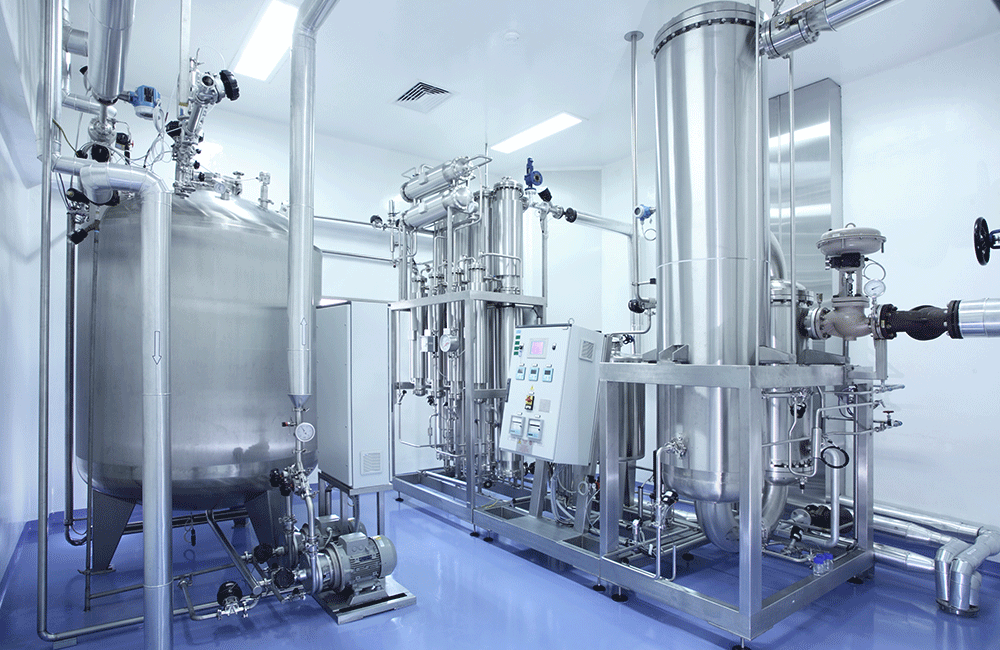

Terminals incorporate a large range of systems, assets and ancillary equipment. Whether storage tanks, loading equipment, transmission lines, digital controls, supply systems or support buildings, all assets should be evaluated for the optimal selection.