Recalls are among the most disruptive and costly challenges in food manufacturing. Industry leaders view both recalls and near-miss events as critical opportunities for improvement.

Rather than stopping at identifying the failure point, root cause analysis digs deeper to uncover systemic issues, such as gaps in training, sanitation or supplier oversight. The insights gained are used to revise hazard plans, refine production workflows and retrain staff, often resulting in internal standards that exceed regulatory requirements.

While regulatory frameworks have improved traceability, the real test of a food safety system lies in recall management, both the preventive measures and how quickly and effectively a company can respond when contamination occurs.

Modern recall effectiveness depends heavily on integrated digital traceability systems, linking warehouse management systems, manufacturing execution systems, IoT sensors and enterprise resource planning (ERP) databases into a unified data flow. This allows real-time tracking from receipt of raw materials to product distribution, enabling precise, targeted recalls that reduce scope, cost and brand damage. Many manufacturers are also adopting global data standards such as a GS1 digital link to allow interoperability across suppliers and international markets.

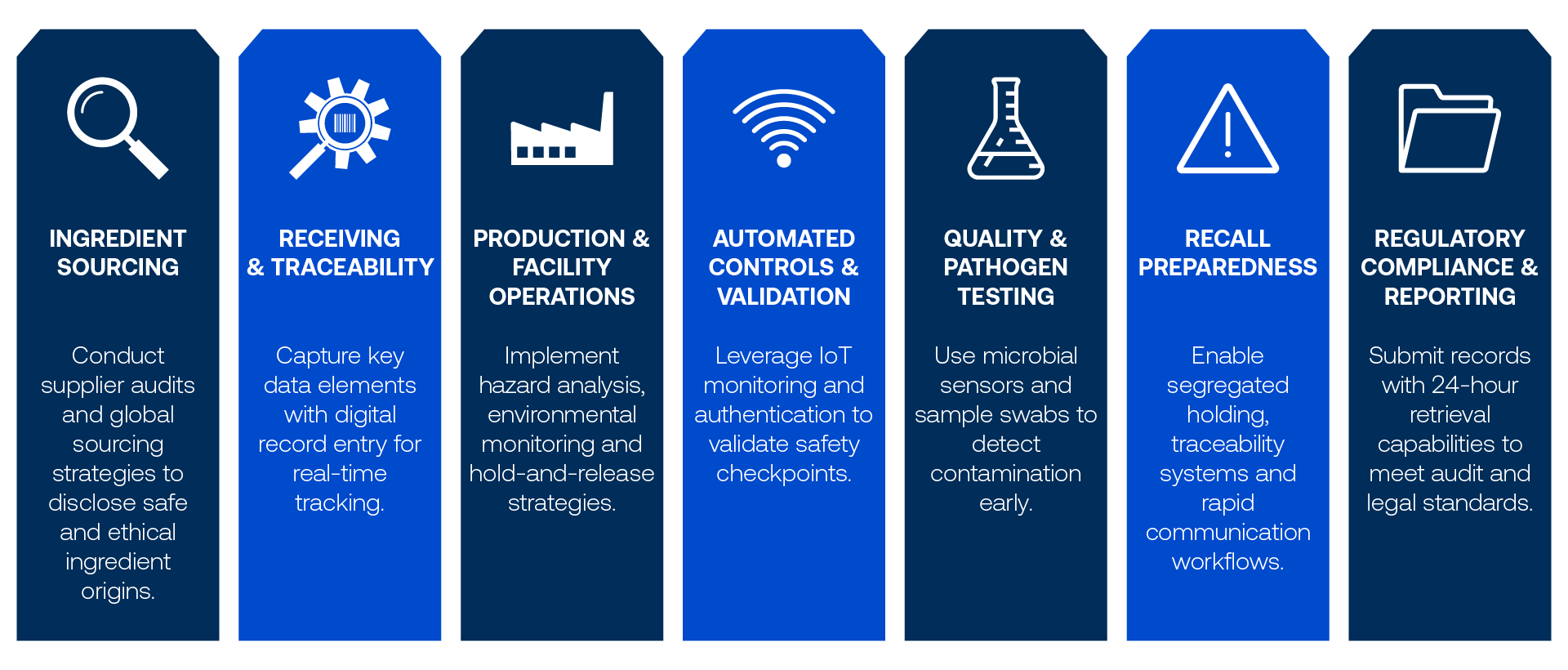

With changing consumer preferences as well as other external factors, modern facilities are transforming to meet current challenges. Key factors tied to recall management include:

- Segregated zones. These are essential for separating raw materials from ready-to-eat products, reducing the risk of cross-contamination. These zones are often physically divided by walls, air locks or sanitation stations to preserve strict hygiene boundaries.

- Controlled traffic patterns. These help direct personnel, equipment and materials through facilities in ways that prevent the introduction of contaminants. Measures include: designated pathways, restricted access points and directional flow systems that separate clean and dirty operations. Simplicity is crucial. Keeping control processes intuitive promotes compliance, while complex processes can lead to shortcuts and nonadherence.

- Environmental monitoring systems. These provide continuous oversight of critical conditions such as temperature, humidity and microbial presence. These systems enable early detection of potential hazards and support timely corrective actions before contamination can spread.

Continuous environmental pathogen monitoring, strategically placed microbial sensors, automated air sampling and real-time cloud reporting is becoming standard for high-risk areas. For ready-to-eat products, many facilities employ a hold-and-release protocol, withholding distribution of finished lots until pathogen testing confirms safety. This approach, when automated, allows both rapid clearance of safe product and containment of contaminated batches.

Despite ideal efforts, even when using advanced preventive food safety measures, contamination and recalls can still happen. That is where reaction protocols come into play.

The core of recall response lies in lot tracking and traceability. Manufacturers aim to limit the size of production lots so that in the event of contamination only a small, well-defined batch needs to be pulled. Automation has made this more precise. Sensors and digital systems now collect detailed data throughout the production process, allowing manufacturers to pinpoint the exact time and location of a contamination event. This data-driven approach not only speeds up the recall process but also reduces its scope and cost.

When a recall is triggered, manufacturers must act fast. It is important to identify the affected lot, trace its distribution and initiate a root cause analysis. This investigation can take months and often leads to new internal standards that exceed regulatory requirements. In all sectors of the food industry, manufacturers are often ahead of regulators, using lessons from past recalls to drive continuous improvement.

Ultimately, the goal is not just to react to recalls but to design systems that make them less likely and less damaging. From X-ray inspections and AI-driven defect detection to supplier audits, customer-driven quality demands and changing regulations, the industry is moving toward a more resilient, data-informed, traceability-centric model of food safety.