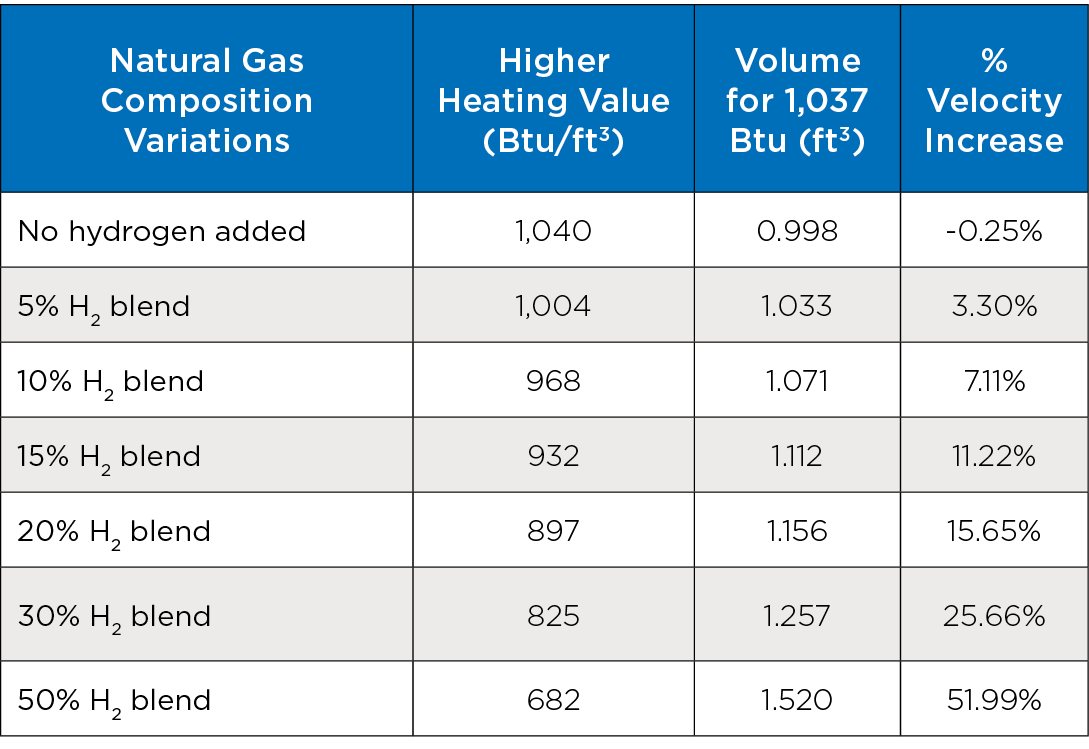

The velocity for blended gas containing up to 20% hydrogen is typically less than 60 feet per second (ft/s) across different types of residential, commercial and small industrial loads, based on average gas consumption and service line size. This falls within the 60-80 ft/s industry standard for natural gas to safely pass through a service line. A velocity of less than 100 ft/s is preferred for the safe and reliable operation of a pipeline system.

Increasing the flow rate of an 80-20 blend of natural gas and hydrogen has other advantages. For example, this gas blend is found to be interchangeable with 100% natural gas on the Wobbe Index, with consumer appliances experiencing no ill effects from the flow rate increase, according to ATCO, which conducted a hydrogen blending project in its Fort Saskatchewan natural gas distribution system in 2022. Some residential and commercial gas meters, however, could be impacted if the flow rate nears or exceeds the meter’s maximum capacity. Residential flow meters commonly range in capacity from 200 to 400 ft3 per hour.

Natural gas blends with higher concentrations of hydrogen are problematic. For 30% and 50% hydrogen blends, gas velocity through the pipeline would need to increase to as much as 70 ft/s to restore the energy capacity lost through blending.

While this flow velocity increase does not compromise pipeline integrity or safety, it raises other concerns. For example, increasing flow velocity by 20% or more can create a constant low humming sound in pipelines. This noise could be disruptive to residents, given that portions of service lines are located above ground and on the exterior walls of residences. Care should be taken so that the increased flow velocity stays below the erosional velocity of the pipe material to prevent any integrity concerns and potential material failure.

This study considered only residential and commercial applications for hydrogen blends. Industrial and turbo gas applications require different considerations. Further study is needed to evaluate the use of hydrogen-blended natural gas in these applications.

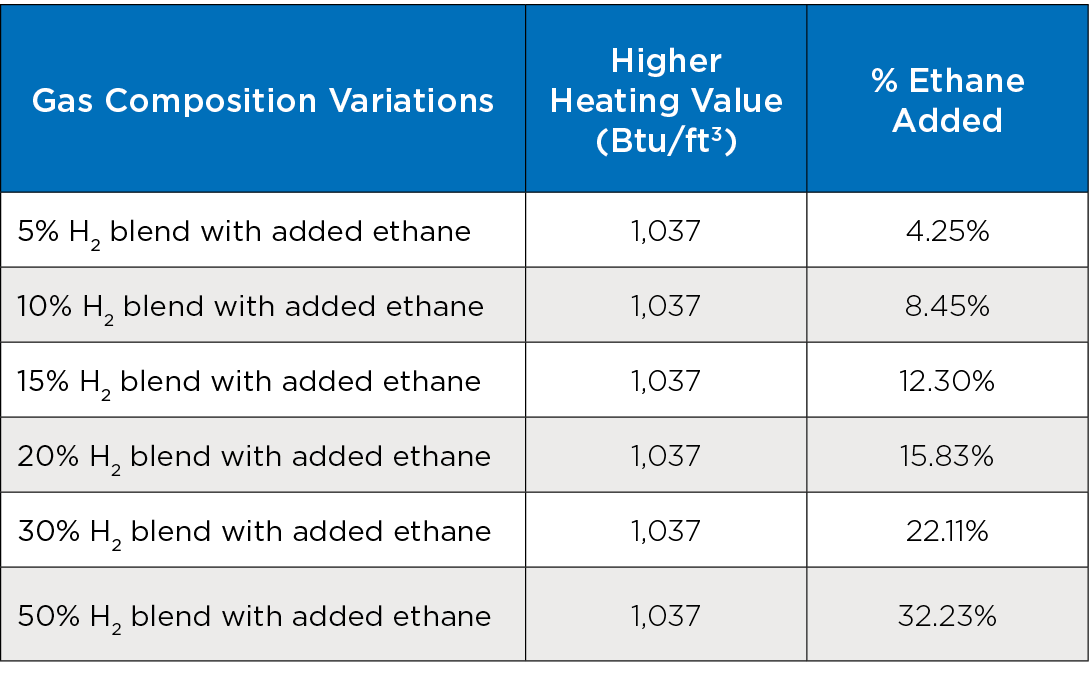

Option 2: Adding Ethane to Blended Gas

While increasing the flow rate of hydrogen-blended gas can restore the energy lost in blending, adding ethane to blended gas can achieve a similar effect.

A small amount of ethane is present in all variations of natural gas. Adding a greater concentration of this hydrocarbon, which is fully miscible and will not separate, to hydrogen-blended natural gas increases the energy content of the gas and restores it to levels closer to the U.S. national average.

For this study, Burns & McDonnell calculated the percentage of ethane that would need to be added to be added to various concentrations of hydrogen blends to achieve 1,037 Btu/ft3 (See Figure 3). The results indicate that the optimal 20% hydrogen blend would require a 15.83% concentration of ethane to achieve the desired result.