Increasing the Range of Irradiance Values

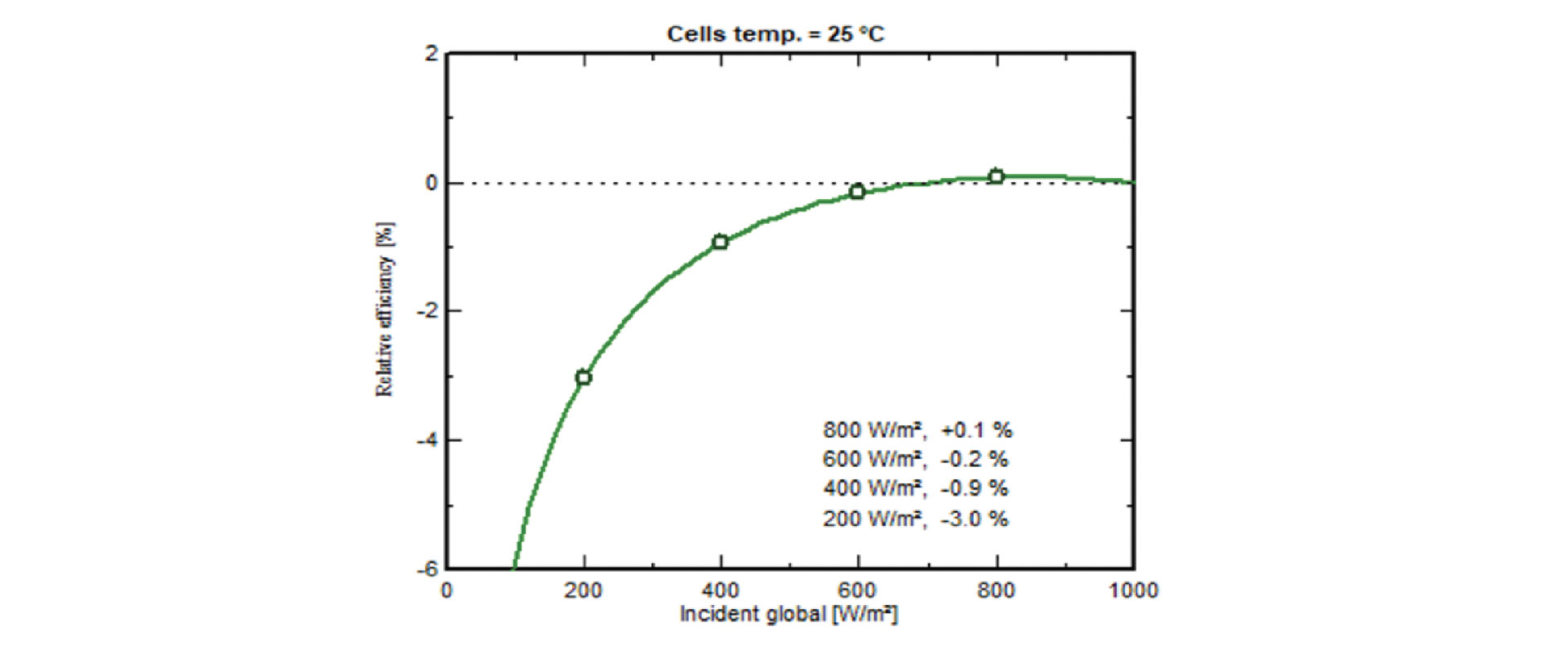

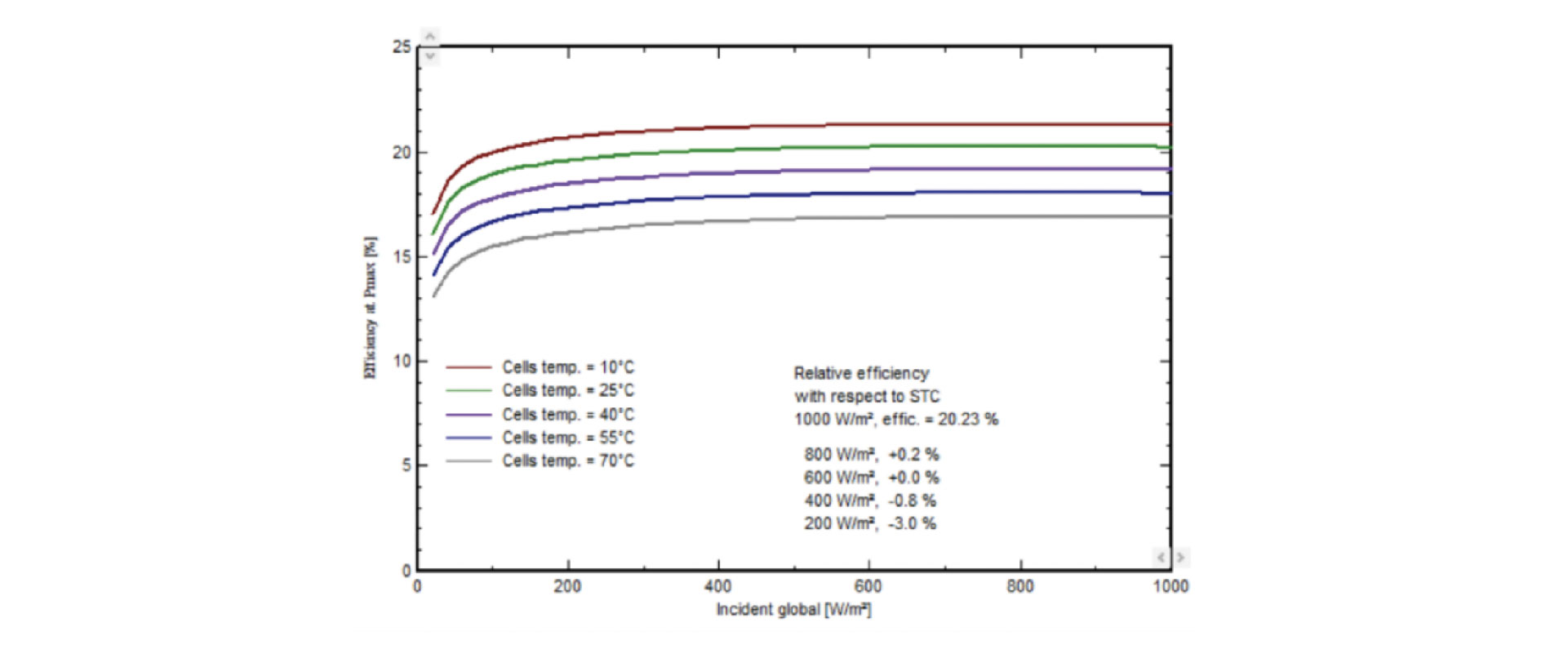

Lowering the minimum irradiance used can be very useful in the winter and farther from the equator when irradiances above 400 W/m2 are rare or even impossible, even on a sunny day. A common value used is 300 W/m2. The main disadvantage to this approach is that PV module efficiency becomes noticeably nonlinear at that range though not as nonlinear as in the 100-300 W/m2 range. However, with the ASTM E2848 regression, the impact of nonlinearities is reduced by 1) evaluating the regression at an irradiance within the measured data, and 2) using a limited range of irradiances where the effect of the nonlinearities is also limited. However, the use of low irradiances with regressions evaluated at 1,000 W/m2 or other high irradiance values is not recommended due to the higher impact of the nonlinearities including extrapolation error.

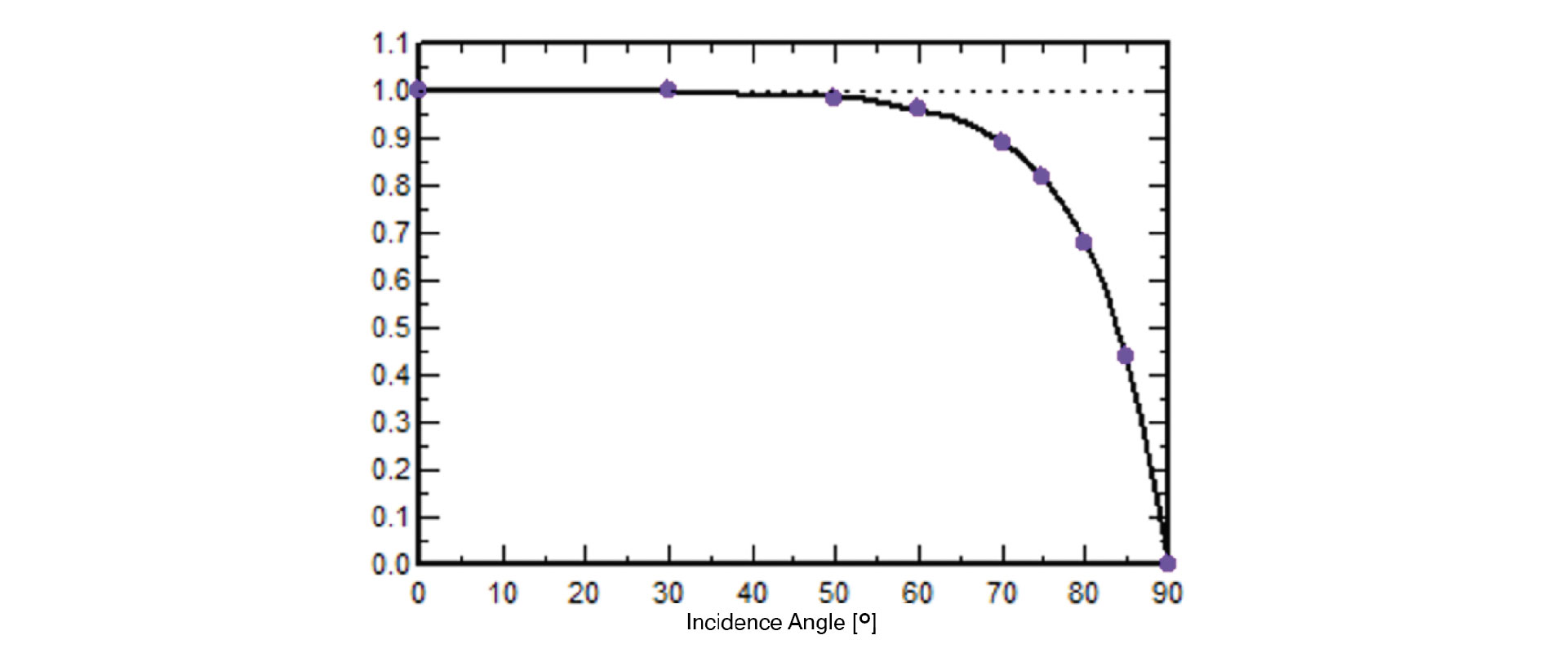

A second disadvantage is that the incident angle modifier (IAM) losses are greater (and nonlinear) with low sun angle, introducing additional errors. However, low irradiance due to overcast conditions does not have this disadvantage and can be used. Sunny time periods with high IAM losses can be filtered out based on time stamps.

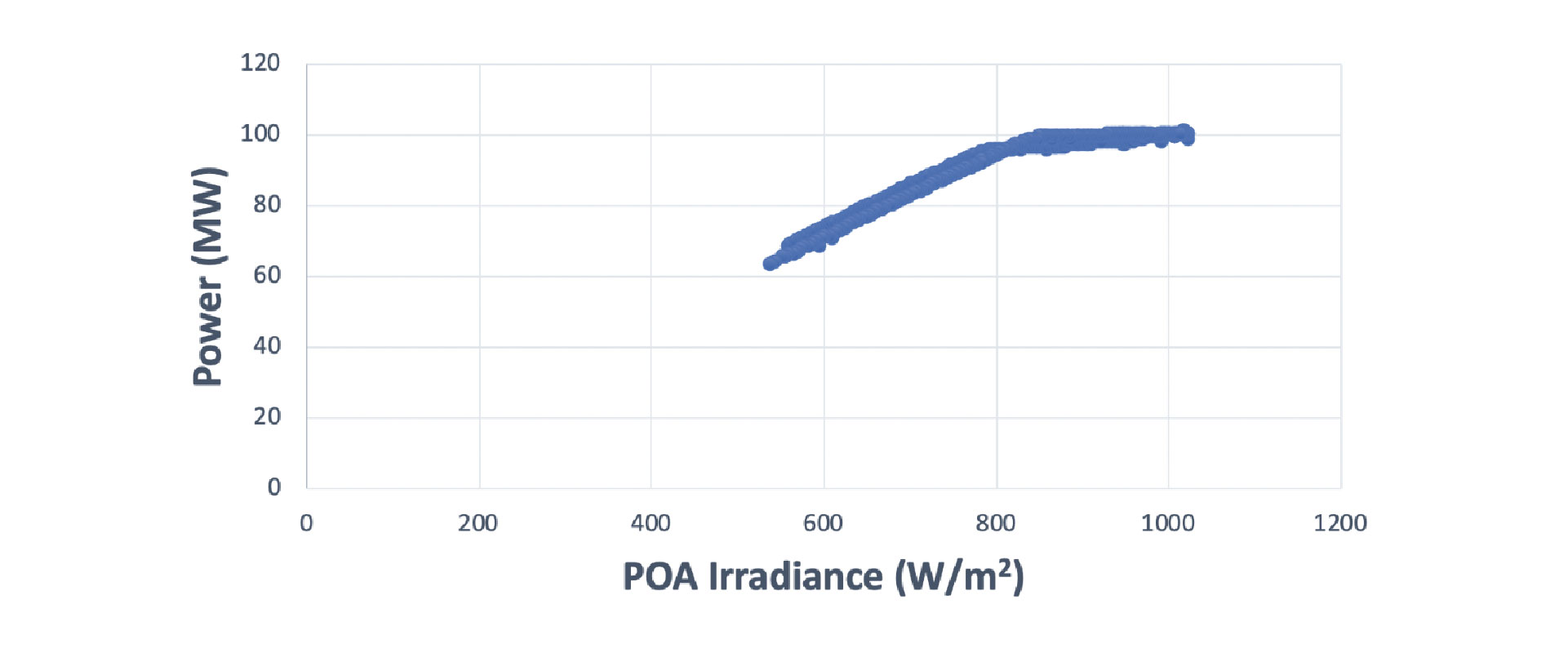

Increasing the range of irradiance values at levels higher than 400 W/m2 used in the test is actually recognized in ASTM E2848. That standard recommends using irradiances only ±20% from the RC irradiance but supports the use of expanding the range in order to collect more data points.

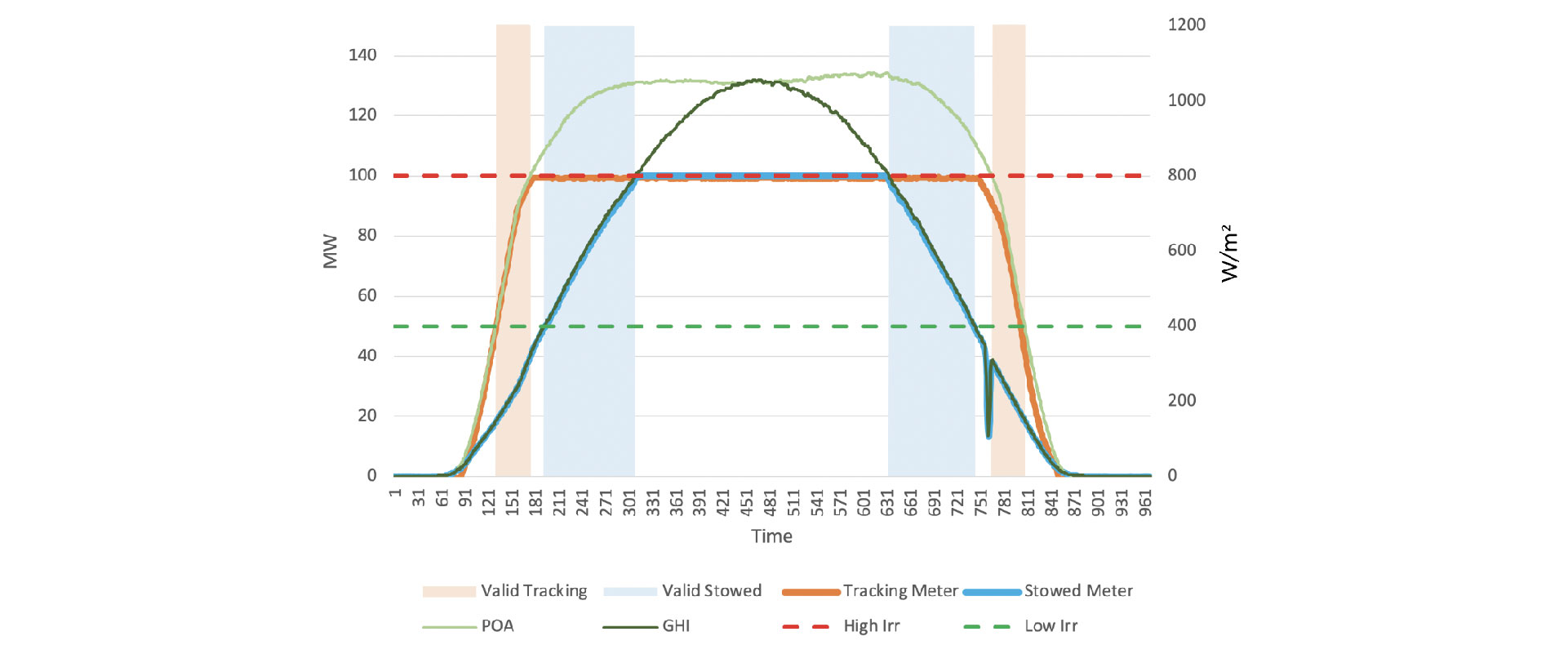

Temporarily Reducing the DC Capacity

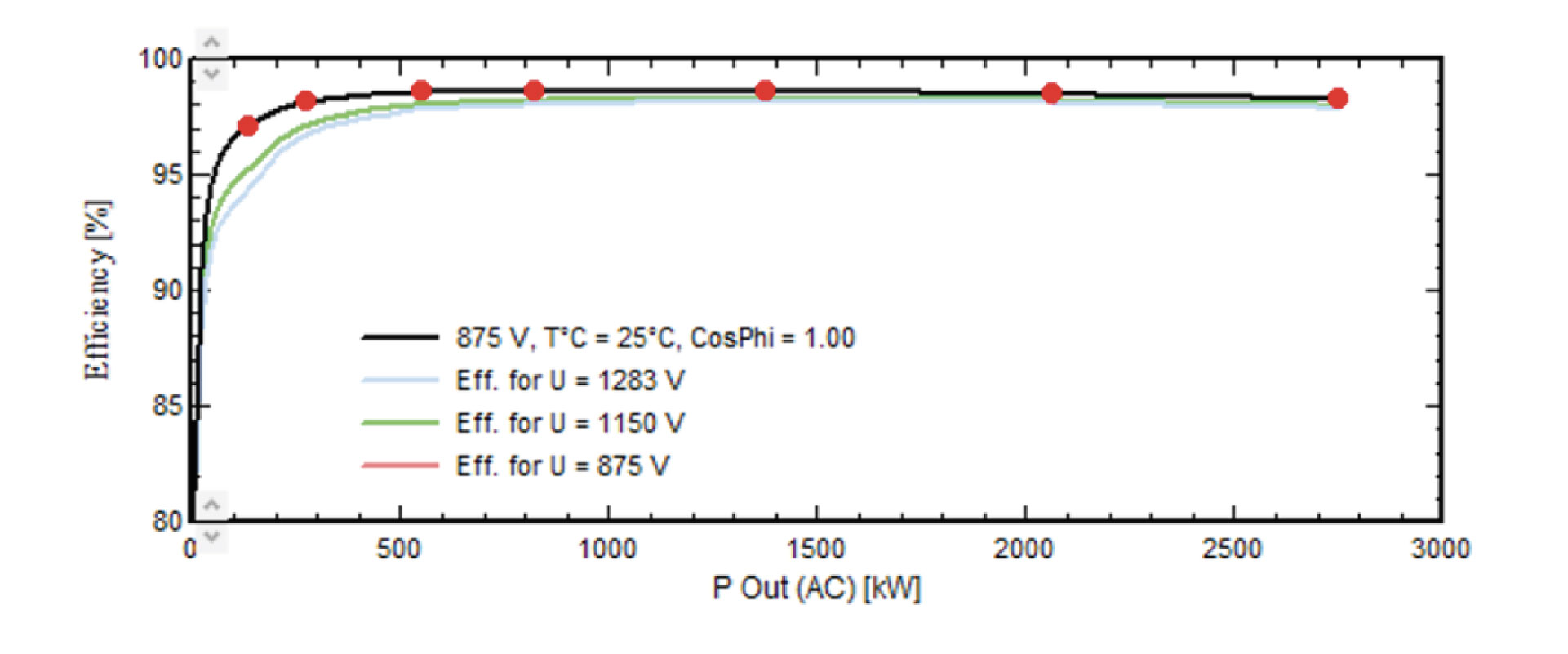

When clipping is an issue, rather than stowing the trackers, the DC capacity of the PV arrays can be temporarily reduced by opening the switches on a limited number of combiner boxes. The PVsyst model would also need to be modified to reflect the reduced DC capacity. In this case, the overall results would need to be scaled in order to truly reflect the plant’s full capacity. Ideally, the offline combiner boxes would be rotated with online combiner boxes and the test run twice. This would allow a test of every portion of the PV arrays with results combined to present the full capacity. Less ideally, the current output of the temporarily offline combiner boxes could be compared with the online ones under similar conditions to ascertain that the power outputs are indeed proportional.

Use of Limited Data Points With Horizon or Near Shading

While not ideal, the limited use of data from time periods with minimal shading from trees or other objects can be used, especially if the plant goes rapidly from shaded periods to clipping. The shading percentage can be calculated by PVsyst and/or observed in the field. The authors’ experience with this approach is that allowing time stamps with shading less than 3% can still produce usefully accurate regression results. If based on PVsyst hourly data, it is prudent to use measured data only from the second half-hour of the corresponding time stamps in the morning and the first half-hour in the afternoon to avoid time periods with shading more than 3%. If this approach is used, the test uncertainty will increase and should be acknowledged.

Preferably, one of the other mitigation strategies such as stowing the tracker or reducing the DC capacity should be tried first to avoid the additional errors and uncertainties in using data with limited shading.

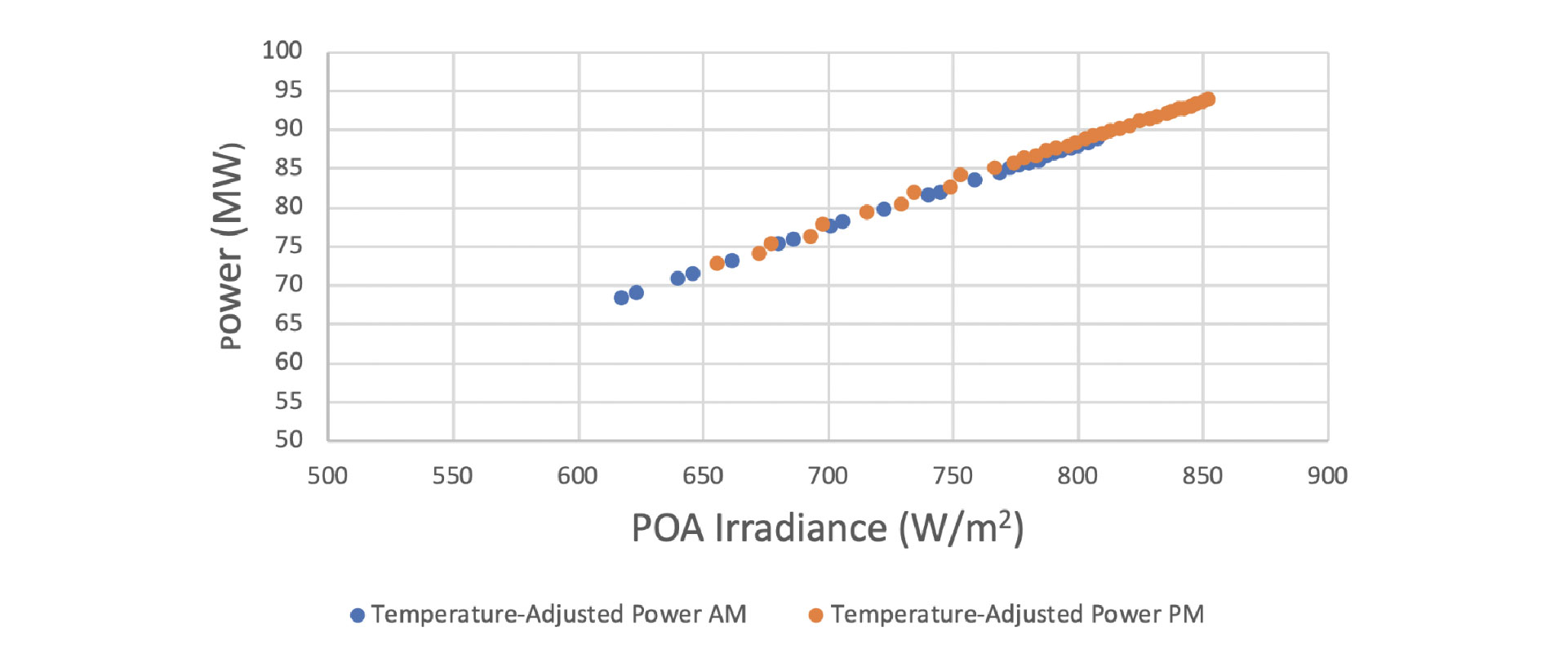

Reducing the Number of Data Points Used in the Regression

When the data are relatively consistent, a reduced number of data points can be used and still provide a valid regression. This is already done with PVsyst data since they are usually in an hourly format. Similarly, as few as 50 measured 1-minute or 5-minute data points can produce good regressions with consistent data. The linearity of the data can be evaluated via the coefficient of determination (R2 where R is the Pearson correlation coefficient). While other data consistency parameters can be used as a supplement, an R2 of 0.93 or above can be considered a reasonable lower limit. When this approach is used, a good additional validation practice is to identify two or more actual data points close to the RCs and compare their output power to the regression results. Collecting data from at least two or three days, as specified in the IEC and ASTM standards, respectively, is an important requirement for this test modification. All of these factors must be considered when agreeing to a reduced number of data points, and it is not possible to predetermine an absolute minimum a priori.