Changing the Rules of Pipeline Integrity

Phase 1 of changes to the PHMSA’s 49 CFR Part 192, commonly referred to as the gas mega rule, focuses largely on the integrity of gas transmission pipeline systems. To improve integrity management and safety of natural gas transmission pipelines, PHMSA is requiring operators to confirm the material specifications and maximum allowable operating pressure (MAOP) of assets located within a broader range of locations and operating conditions. Operators must also begin assessing transmission pipeline segments within a broader range of location classifications.

MAOP and Material Verification

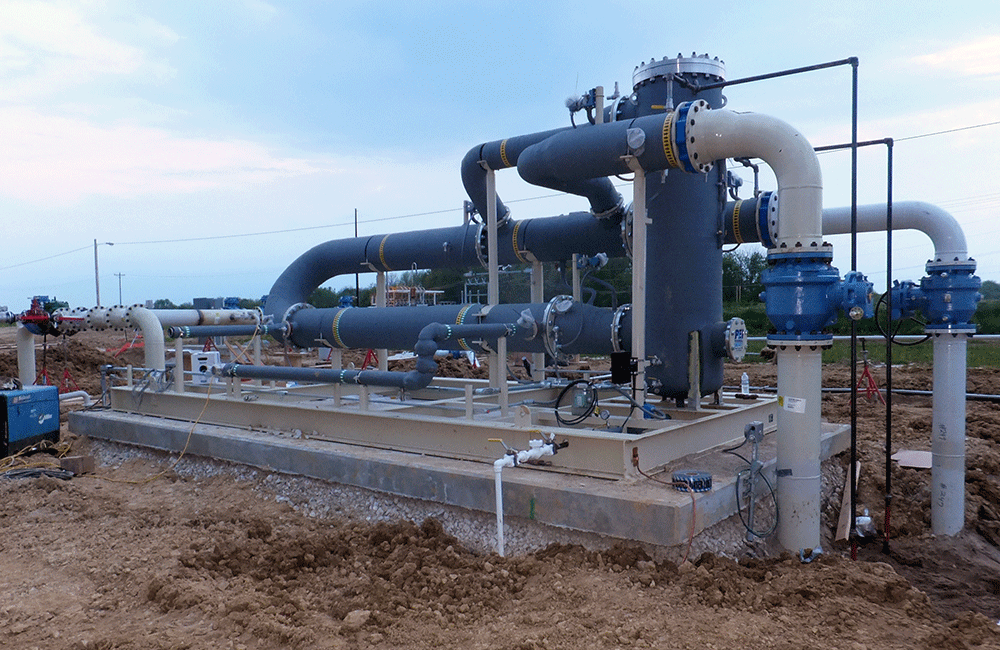

A significant portion of the phase 1 rule outlines documentation requirements that confirm the MAOP and material specifications of transmission pipeline assets within high consequence areas (HCAs), moderate consequence areas (MCAs) and Class 3 and 4 locations, as defined by 49 CFR Part 192. The newly defined MCA is an onshore area as defined in 192.903, containing five or more buildings intended for human occupancy; an occupied site; or a right-of-way for a designated interstate, freeway, expressway or other principal four-lane arterial roadway. Specifically, PHMSA requires operators to obtain and keep records on pipe and components, such as valves or fittings, for the life of the asset that document:

- Chemical composition

- Pipe diameter

- Pressure rating (if applicable)

- Seam type

- Strength test records

- Wall thickness

- Yield, or ultimate strength

PHMSA requires that records confirming MAOP and material properties must be traceable, verifiable and complete. If an operator does not have sufficient documentation for a specific pipe segment or component, and the asset is located in an HCA, MCA, Class 3 or Class 4 area, the operator will need to reconfirm the MAOP of that asset.

PHMSA outlines six approved methods for reconfirming MAOP:

- Pressure test

- Pressure reduction

- Engineering critical assessment

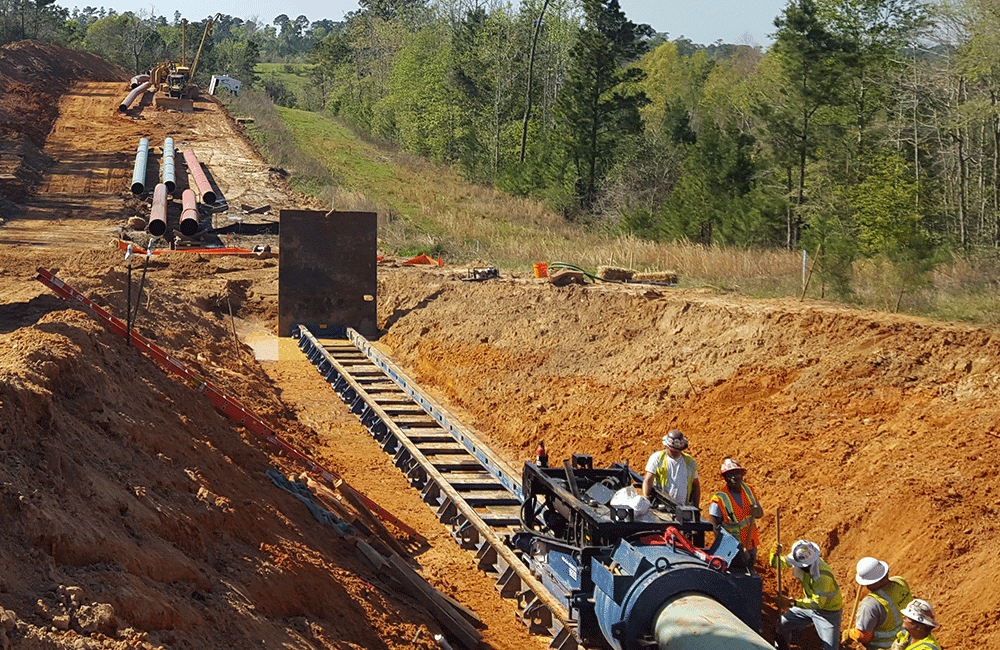

- Pipeline replacement

- Pressure reduction for pipeline segments with a potential impact radius less than or equal to 150 feet

- Alternative technology

The regulations also detail requirements for how operators should verify material properties. If operators do not have records on pipe and components, they must develop and implement procedures for conducting destructive and nondestructive tests to verify material properties. Material properties for on-line pipe components also must be verified. To verify material properties for a population of pipeline segments that are missing records, a sampling program may be implemented.

Perhaps the most significant change within the new regulations is the now limited applicability of Part 192.619, commonly referred to as the “grandfather clause,” for confirming MAOP. Prior to the new rulemaking, the grandfather clause allowed operators to confirm MAOP using the highest pressure recorded within a five‑year period that pre-dated July 1, 1970. The grandfather clause allowed operators to verify MAOP on virtually all existing transmission pipeline segments that were in service prior to July 1, 1970. The grandfather clause can now only be used to establish the MAOP of pipelines that operate under 30% specified minimum yield strength (SMYS) or pipelines that operate in a Class 1 or Class 2 area. This means that all previously grandfathered pipelines that operate above 30% SMYS within Class 3 and 4 areas, or within HCAs and MCAs, must have their MAOP reestablished.

Operators have until July 1, 2021, to document their plan and procedures for identifying assets covered within the new rule that do not meet the verification requirements for MAOP and material specifications. The plan must also include the process and procedures the operator will take to verify the MAOP and material properties of 50% of covered assets by July 3, 2028 and 100% by July 2, 2035.

Since these requirements are driven by class location and consequence area, operators will also need to undergo data collection to determine class locations and HCAs or MCAs. This will inform which assets need to be analyzed for MAOP and material verification.