Boundary Conditions

Every model requires specific boundary conditions to be set to limit the scope of the analysis. PSA models can get very large and result in taking hours to run an analysis, so for large facilities it is recommended to break up each model into sections. Where to divide the facility into different models and how to handle the transition zone between sections are further considerations.

Another unique type of boundary condition involves long pipelines entering or exiting a station. In these cases a virtual anchor length calculation should be performed to determine the length of the pipeline alignment that should be included in the analysis, as it could impact the pipe stresses inside the station.

Engineers should avoid using rigid anchors in most situations, especially at equipment connections, as these can result in dramatically higher pipe stress. They are also unrealistic, as there is nothing that is truly infinitely stiff. Determining these points’ stiffness can be a significant challenge. In general, the stiffer the anchor, the higher that pipe stresses will be at the anchor point and therefore the more conservative the analysis. Stress within the pipe will be higher than actual, but the load on supports outside the equipment will show up lower in the analysis than actual.

Some anchor points may also call for the addition of a thermal anchor movement, such as connections to a tall contact tower. The connection point to the vessel can shift slightly with the vessel as it thermally expands and contracts.

Soil Properties

Many sites have some buried line segments and therefore require soil properties to be applied to evaluate the overburden loads and the resistance to pipe displacement from the soil springs. PSA software will provide multiple calculation methods, such as those from the American Lifeline Alliance or Pipeline Research Council International, and a few standard soil properties to choose from. Ideally, soil properties should be based on geotechnical surveys taken at the site to accurately reflect the conditions, but this information is not always available. Loose sand can be a conservative assumption, as such less-cohesive soils don’t provide as much support to the pipe, resulting in higher structural support loads. However, this isn’t always a more conservative assumption, as more cohesive soils can restrict pipe movement and lead to higher bending moments near branch connections. Engineers should also remember to verify pipe size, depth and trench-laying techniques when applying soil properties.

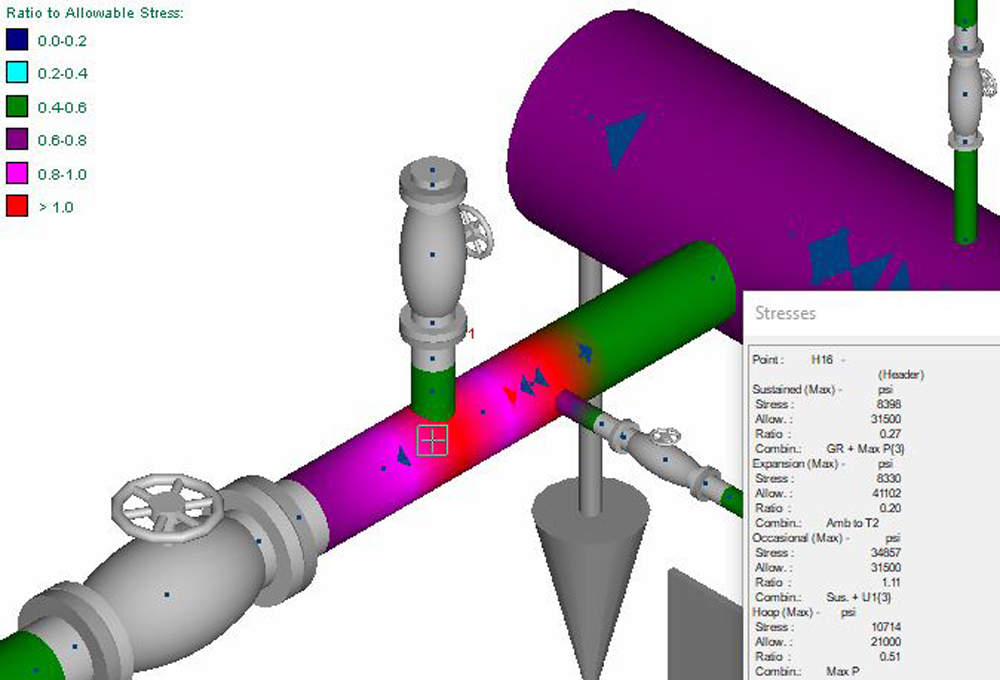

Branch Connections

Piping branch connections are common locations where combined stress might exceed allowable limits. This is due to the stress intensification factors (SIFs) in these locations. Designers should verify that the branch type matches the fitting to be used in the design. Keep in mind that these SIFs are approximations based on code calculations, such as ASME B31.8 Appendix E for common fittings. These SIFs do not account for the number of loading cycles, nor the considerably heavier wall thickness that some cast fittings provide, which can introduce errors into these estimates. One method to improve on the standard branch connections in the PSA model is to use an initial rigid internal segment; a second, thicker-wall short segment to resemble the branch fitting; and then the branch pipe. A user SIF must then be applied manually to the branch segment. In some critical cases, it may be necessary to do a more thorough analysis using a finite element analysis on a 3D model of the part.

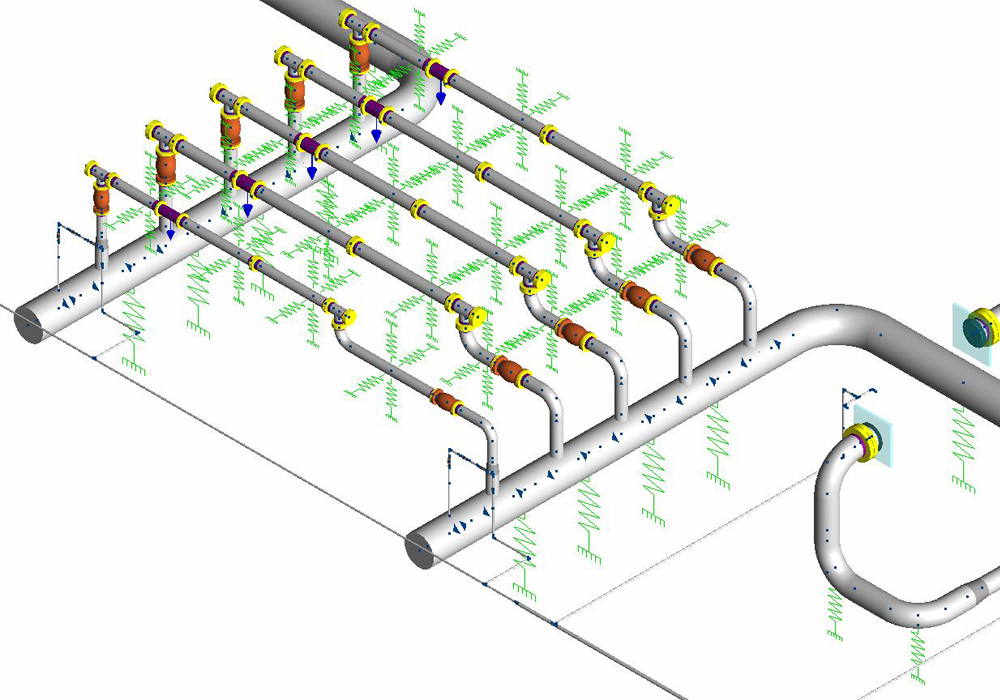

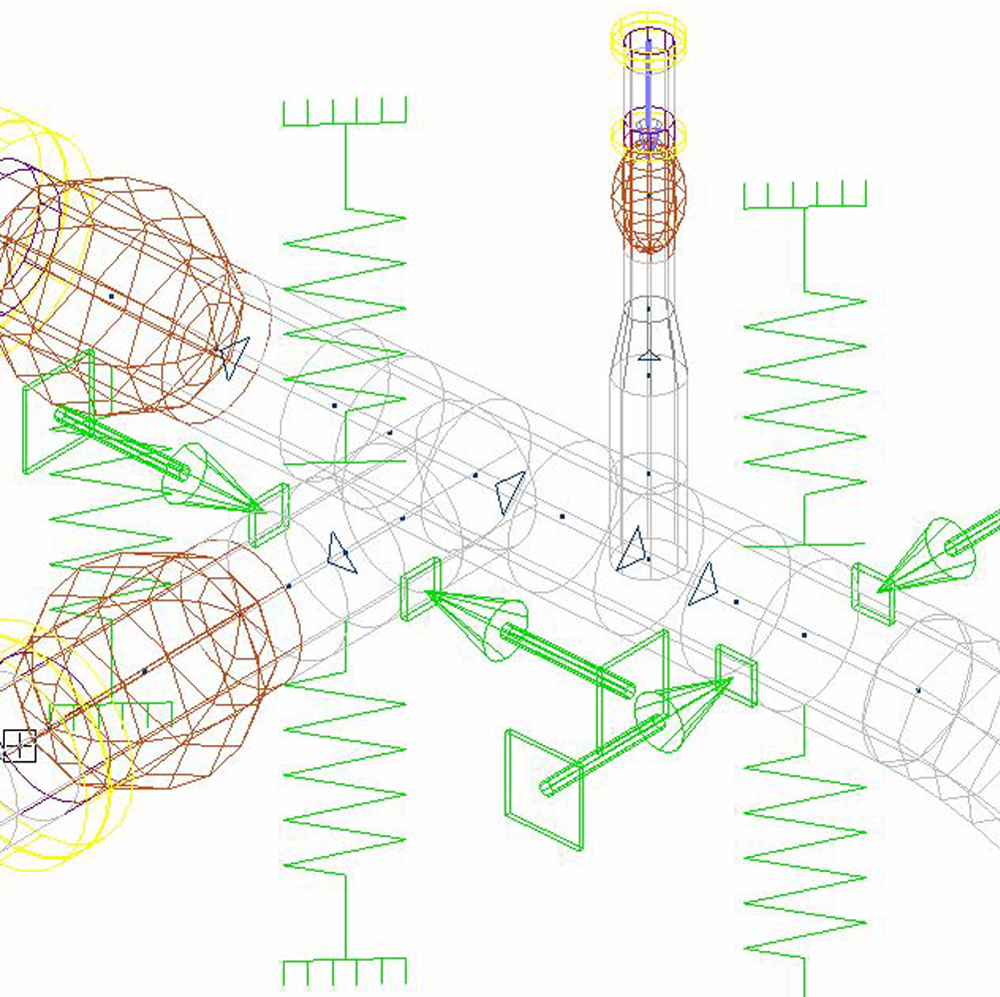

Supports

All pipe supports should be included and modeled as closely as possible. There may be more than one acceptable type of support, and a structural engineer should verify that the selection accurately reflects the support design. Translational stiffness, friction coefficients and guide gaps are key factors to determine, and they vary significantly by direction or support type. Designing pipe supports is often an iterative process in which the piping designer approximates an initial, conservative support layout design, then shares the support reactions with a structural engineer to refine the design. Then the analysis is updated to reflect the improved design.

Operational Load Cases

Determining the appropriate pressures and temperature cases to analyze is critical to any PSA. A typical approach is to analyze a common operational scenario or base case and two more extreme operational scenarios, with both at the system maximum allowable operating pressure: one at minimum temperature and the second at maximum operating temperature. Selecting the appropriate temperature range can be challenging, however, because simply using the full design basis temperature range for specified equipment can lead to overstressing and be unrealistic compared to most steady-state transmission line operations. Buried pipelines are typically isothermal in nature and operate at moderate temperatures. There is the added complication of the neutral stress state or ambient temperature that is chosen because in reality this will depend on the weather at the time when the lines are installed. One approach to achieve more realistic results is to separate above-ground and underground line segments and apply different temperature ranges to each.

There may be other unusual operating conditions. For instance, if the discharge cooler at a compressor station fails, the piping downstream can experience much higher temperatures than normal. Another example would be a steam-out on a process line in a refinery.

Seismic Loads

For occasional static earthquake loads, use recent industry code calculations, such as ASCE 2016. The version referenced should match the one used by the local municipality. Apply the appropriate site class, importance and component response factors. The Ss value — the spectral acceleration parameter at short periods corresponding to the mapped maximum considered earthquake — must be determined based on the location. Once the seismic accelerations are determined, it is important to apply these seismic loads in various directions along the X-, Y- and Z-axes.

Wind Loads

For occasional wind loads, engineers can use wind profiles generated using standard ASCE 7-16 or input their own wind pressure profile, using the version of ASCE 7 adopted by the local municipality. For ASCE 7-16 wind load calculations, users should adjust the exposure category, basic wind speed, gust and elevation factors. These can vary based on site conditions, but in most cases it is important to apply wind loads in multiple horizontal axial directions. A 45-degree direction between the primary coordinate axes may also be considered. Wind loads should only be applied to above-ground line segments, not to buried line segments or segments that are inside buildings. The ground elevation must also be correctly defined. Select the lowest grade elevation for a site with a slope.

Snow Loads

Snow loads are not often significant for piping assemblies, and for some sites in warmer locations they are not necessary to consider at all. However, they will need consideration for most Midwest and northern pipeline facilities. ASCE 7-16 ground snow loads are readily available, converted to psi units and applied on a per-unit-area basis in the model.

Additional Forces and Displacements

Other loads can be critical design considerations for facilities. These may include blowdown reaction forces, potential soil settlement or the additional weight of components such as strainers, valve actuators and closures. Blowdown forces (see Figure 2) in particular can be a challenge to calculate, as the flow rapidly achieves isentropic, choked flow. For large blowdown stacks or relief valves on higher pressure lines, these reaction forces can be tremendous due to the rapid change in gas velocity and pressure at the outlet stack. When applying these loads, it is important to consider the load case to which they are applied. Blowdown loads are usually applied as an additional user case.