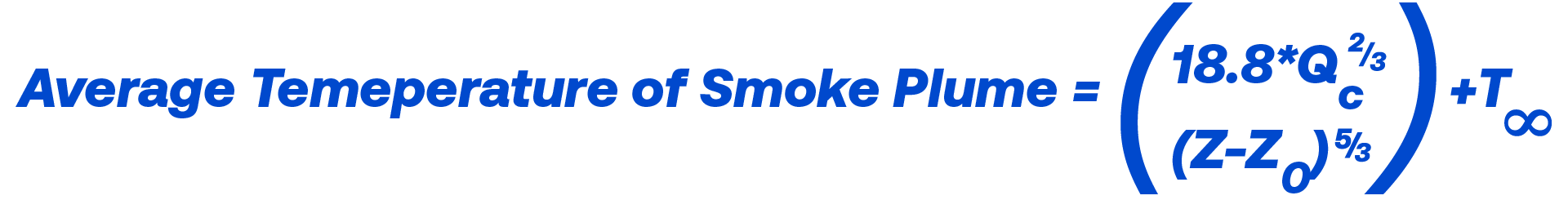

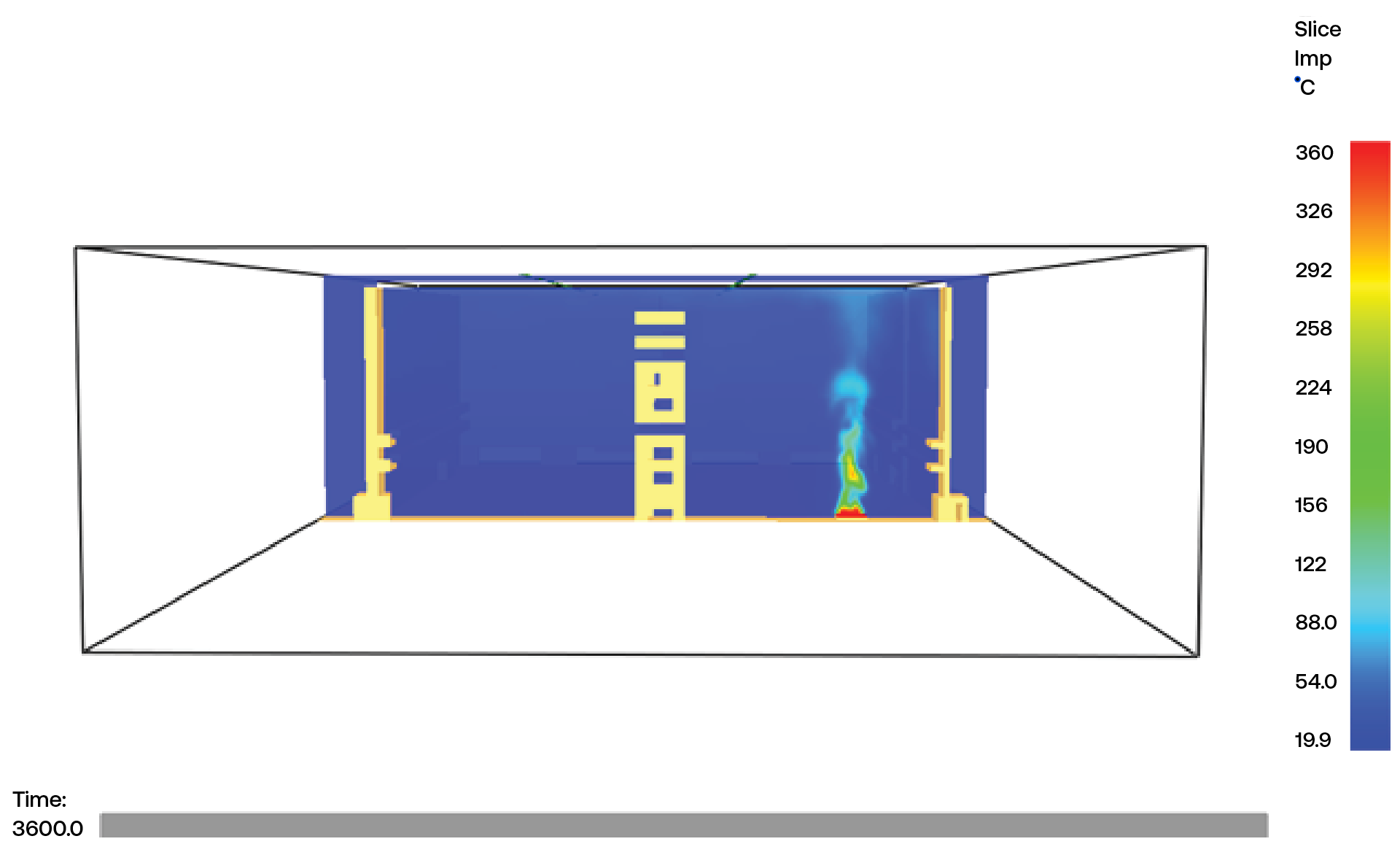

Due to the building's ceiling height, it was determined that a heat release rate of 91,760 kW would be required to activate a sprinkler. As the worst-case fire scenario has a lower heat release rate than is required to trigger a sprinkler, no fire within the examined special-purpose building was shown to activate a sprinkler. FDS analysis was performed to substantiate hand calculations and equation findings. It was determined that the temperature of the smoke plume at the ceiling reached 135°F, which is below the 225°F temperature required for a sprinkler to be activated. Between fire modeling and hand calculations, it was determined the 126-foot-tall ceilings would inhibit the activation of sprinklers in the event of a fire in the building.

With the understanding of the AHJ, the fire protection engineering team decided that since sprinklers were code required for the building — even though the high ceilings rendered sprinklers ineffective — an alternative protection would be required. As an alternative, performance-based design strategies were put in place to determine effective protection that would meet the intent of NFPA-required automatic sprinkler protection. An existing, on-site fire department would be considered the primary means of fire suppression at this facility. By working with the fire department and utilizing the department's familiarity with the facilities and frequency of training in existing buildings, the team uncovered nontraditional methods of improving response time.

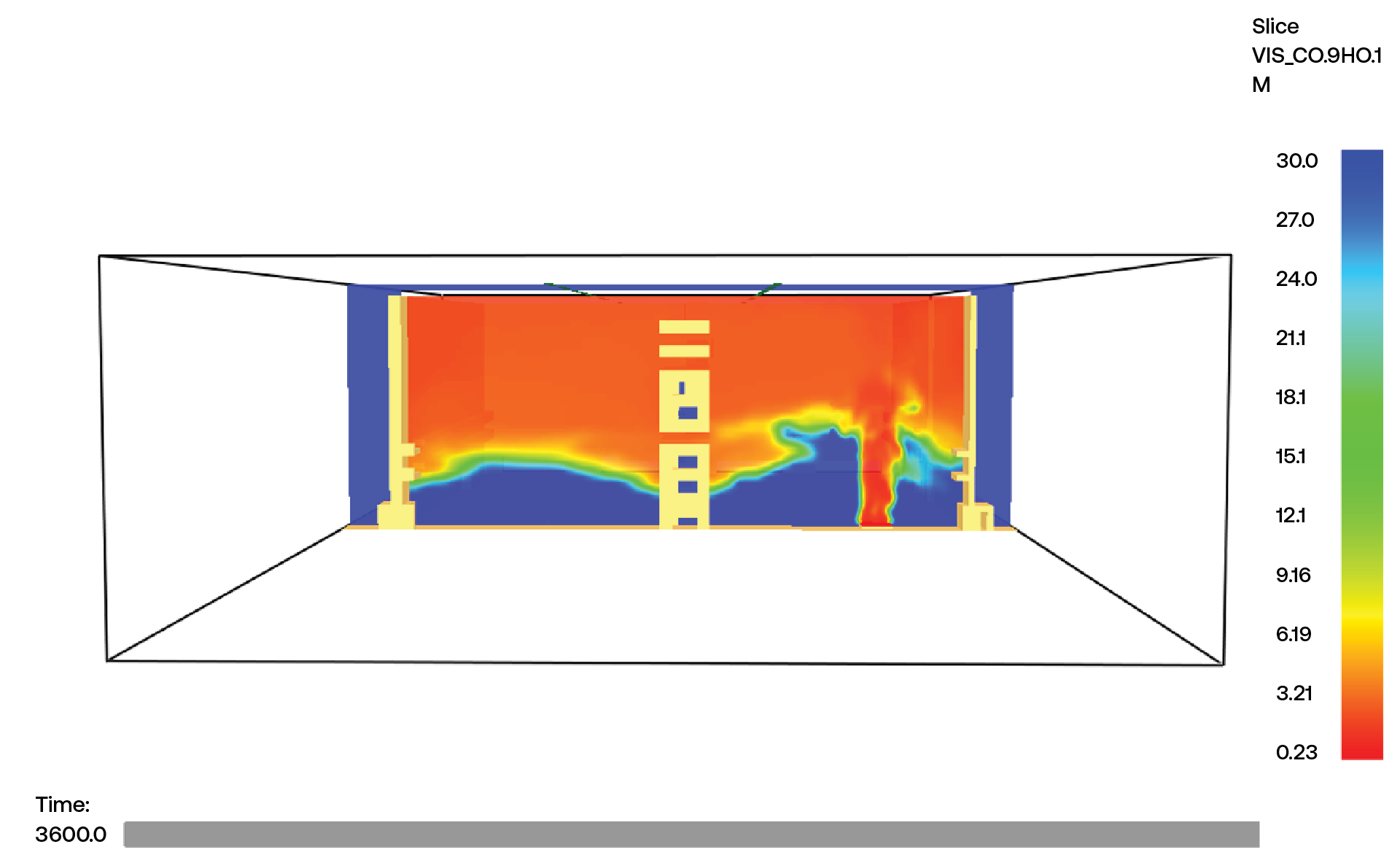

A new automatic standpipe system was designed and spaced closer than prescribed code dictates to allow for faster fire department response. The new automatic standpipe system included hose valve stations in locations that would allow firefighter response to be both above and below fire events, utilizing mezzanines for coverage. In addition, smoke vents located at the ceiling level were increased in capacity beyond code requirements. Hand calculations and FDS modeling were used to confirm that the smoke layer of a worst-case fire would not descend to the breathing height of occupants on the ground level.

Because of the expansive floor area and frequently changing floor obstructions as manufactured parts moved within the building, the travel distances for the space were expected to be in excess of IBC requirements. As a further complication for egress, an open eight-story structure consisting of floors and mezzanines was located through the center core of the facility. The center core structure required life safety analysis to address egress from the space. There was no need for performance-based design alternative protection for facilities that can provide compliant solutions to code-prescriptive egress requirements. For example, while egress travel distance was increased for the designed manufacturing facility, common path requirements and dead-end travel limits were not altered.

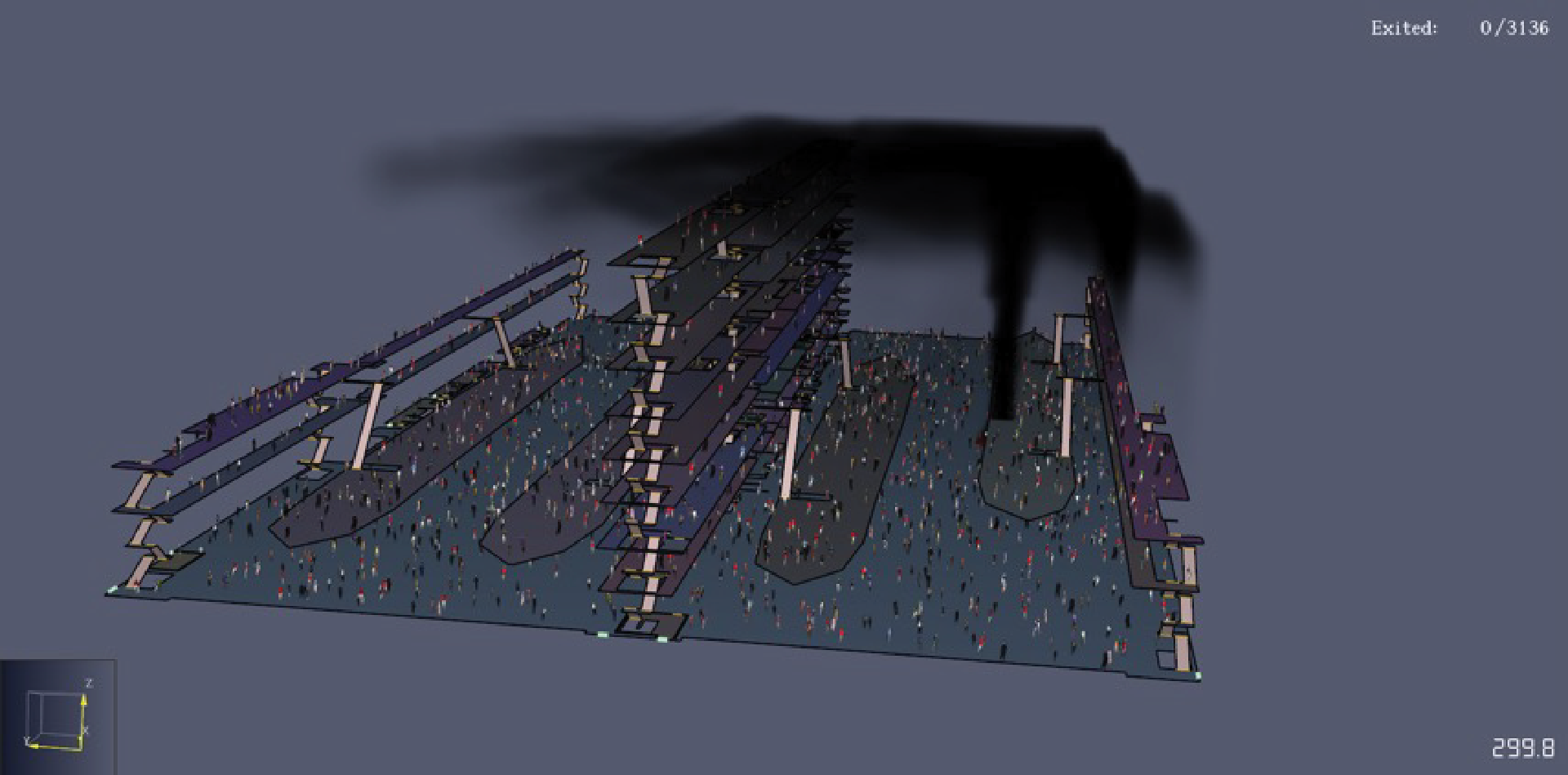

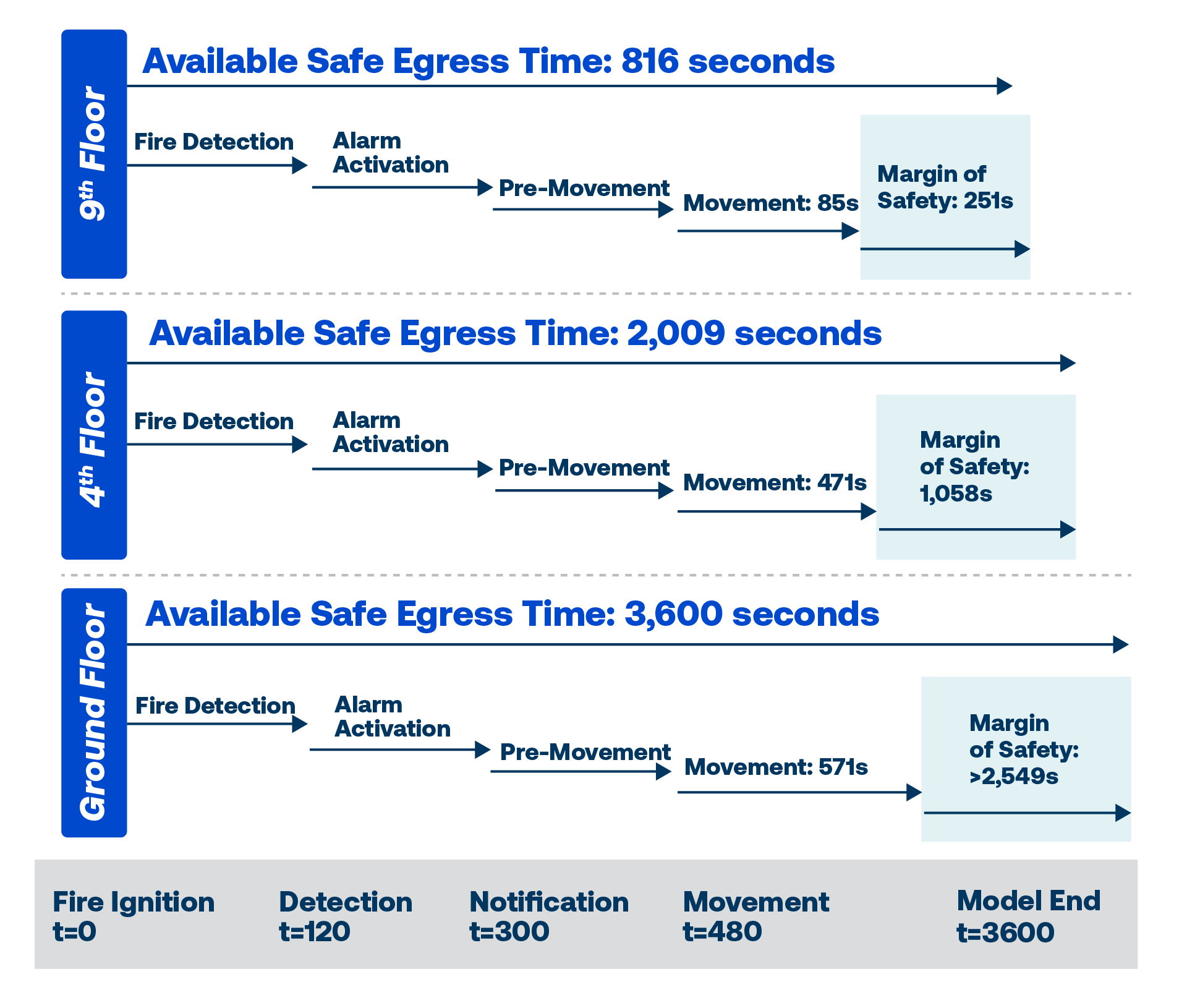

Additionally, for the special purpose industrial facility, travel distance increases were offset not only by a combined fire and egress model verifying travel times but also by dedicated maintained pathways away from the different sections of the manufacturing areas. While special industrial occupancies will require performance-based design for elements of fire safety, code-prescriptive fundamentals, when still effective, are preferable. The Burns & McDonnell team performed egress modeling, supported by hand calculations and paired with FDS modeling, to determine the amount of time it would take occupants to egress the facility. For each floor of the facility, occupants’ egress times were compared to the time it would take for the smoke layer to drop to the floor of occupant egress. Occupants can be considered safe when they have entered an exit passageway or left the building. By providing excess safe egress time, occupants are provided with adequate time to egress the building plus additional time as a safety factor in the event of a fire.