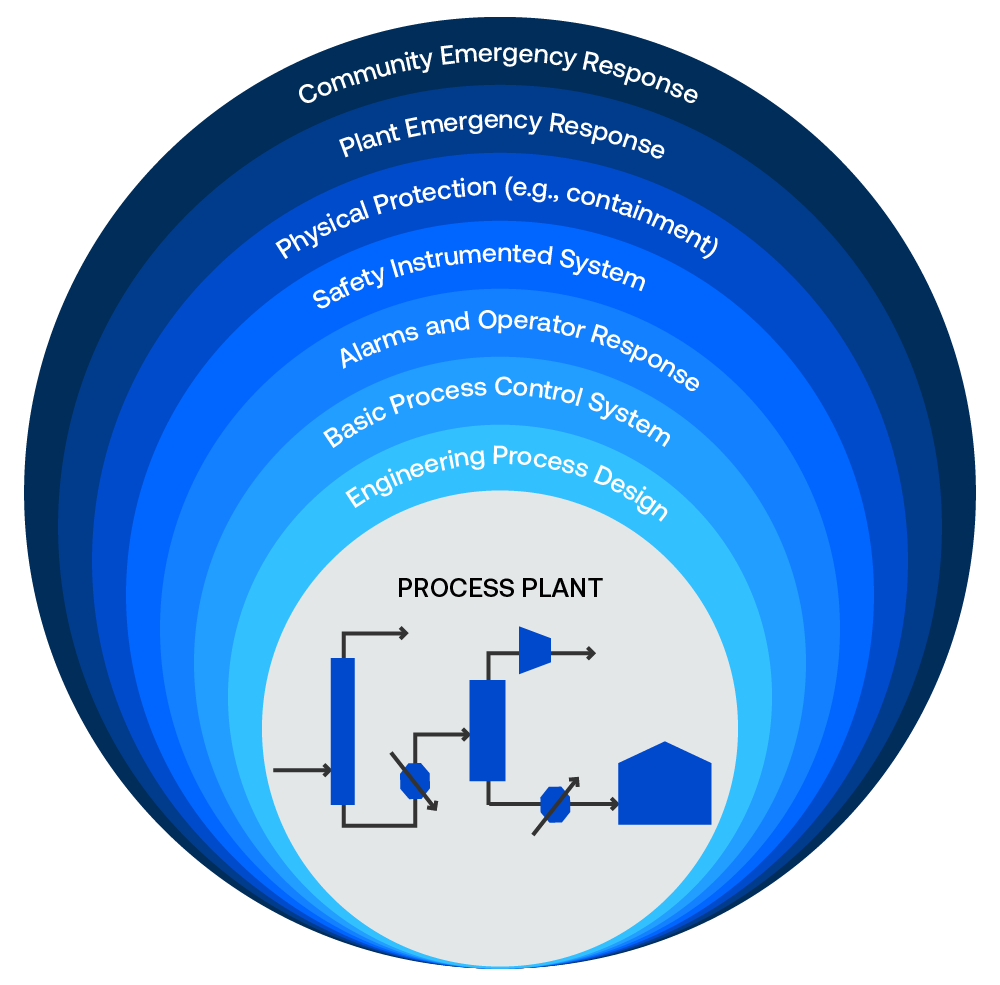

Risks mount wherever people store, process or handle hazardous or toxic materials. In the process industries, these risks are heightened because of their potential to affect numerous people. A spill of a toxic agent or an explosion could be hazardous to people within the plant or in the surrounding area.

There has been an increased focus on industrial safety worldwide. Major catastrophes at Seveso (Italy), Bhopal (India), Piper Alpha (U.K.) and Chernobyl (Ukraine) in the last few decades have brought the need for improved understanding and risk reduction approaches into sharp relief.

Compliance with standards to safeguard personnel and the environment is a priority for both legal and ethical reasons, as well as reducing life cycle costs. Effective safety solutions are needed to enable proactive protection, preventing injuries and saving lives. Eliminating risk entirely and bringing about a state of absolute safety is not practical. More realistically, risk can be categorized as being either negligible, tolerable or unacceptable. The foundation for any modern safety system is to reduce risk to an acceptable or tolerable level. In this context, safety can be defined as “freedom from unacceptable risk.”

The formula for risk is:

RISK = FREQUENCY OF OCCURENCE × SEVERITY OF CONSEQUENCE