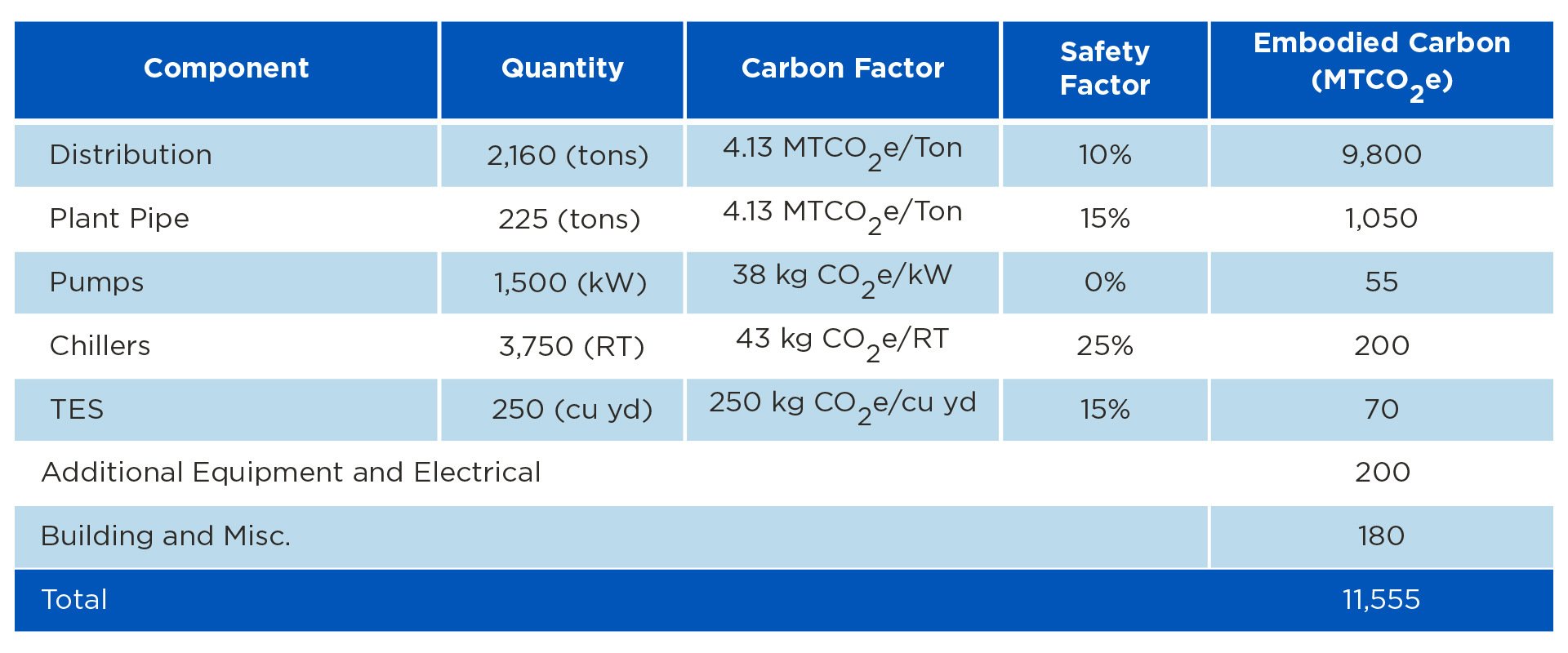

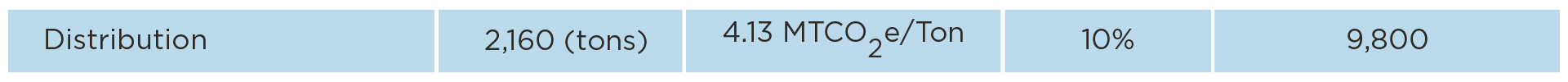

The analysis begins with the distribution system, which will be responsible for transporting hot water across the entire campus and requires a large quantity of steel piping. Based on a projection that 2,160 tons of preinsulated steel will be required, carbon factors based on data sourced from industry-standard EPDs were applied to generate an aggregate estimate for embodied carbon for the distribution system. A safety factor of 10% helps account for uncertainty from EPD data and building distribution.

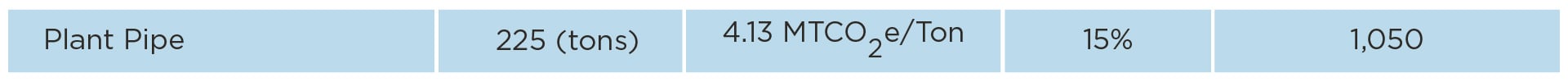

The same logic allows for generating an embodied carbon estimate for the 225 tons of plant piping necessary for plant expansion to house heat pump chillers and hot water components. Here, a slightly larger safety factor of 15% helps account for valves, fittings and instrumentation required for the pipes.

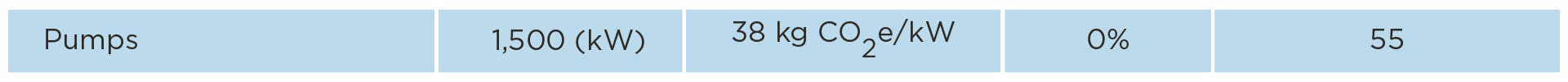

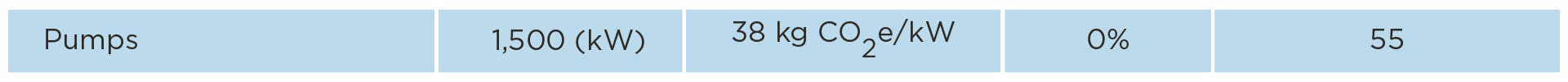

An industry standard EPD also provided helpful data for a similar model of end suction centrifugal pumps to those used in the design. This EPD was scaled to the size of the project’s required pump. In this case, close mechanical similarity allowed for a 0% safety factor.

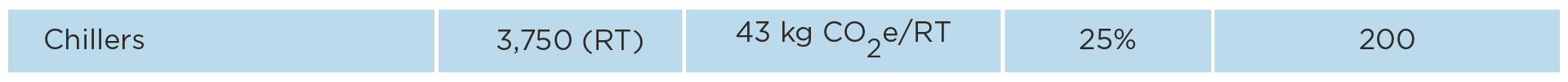

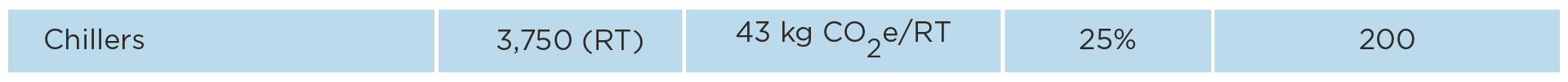

EPDs were not available for the heat pump chillers used in this project design. To generate a workable estimate, a 25% safety factor was applied to the embodied carbon from the EPD for a standard centrifugal chiller from comparable manufacturers to account for a more complex industrial design and dual compressors.

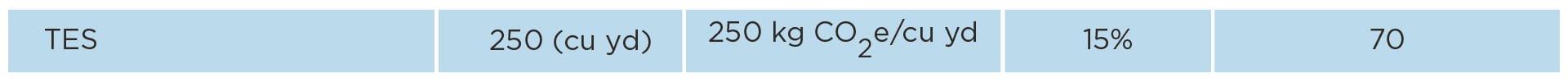

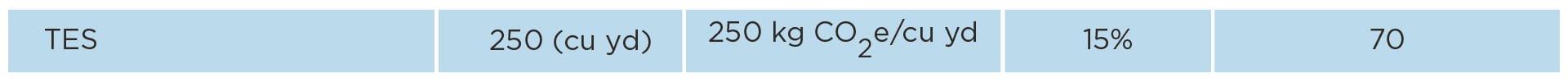

A hot water Thermal Energy Storage (TES) tank would require 250 cubic yards of concrete, with a 15% safety factor added to account for tank internals, instrumentation and other associated complexities. Concrete EPDs are readily available online, and the industry also tracks average embodied carbon across several manufacturers.

After completing projections for the major embodied carbon factors outlined above, an additional 200 metric tons was added to account for additional equipment and systems required by the design, including electrical gear, heat exchangers, water treatment and various other components. This estimate is based on an assumption that the total steel and other materials in these additional components would be roughly comparable to those of the chillers.

Finally, the building size and structural type give us a rough projection of 180 metric tons of carbon for the building’s structure and enclosure. This projection aggregates to 11,555 metric tons of carbon that can reasonably be associated with the materials for this project. Note: This embodied carbon calculation did not account for construction activities, which can add an additional 6-10% of the total for the project.