Horizontal directional drilling (HDD) is a trenchless technique used for installation of pipes, conduits and cables along a specified route. Directional drilling machines and ancillary equipment are used to precisely drill along the proposed alignment and to help utilities get from one point to another with little or no disturbance to the existing infrastructure above and below the surface.

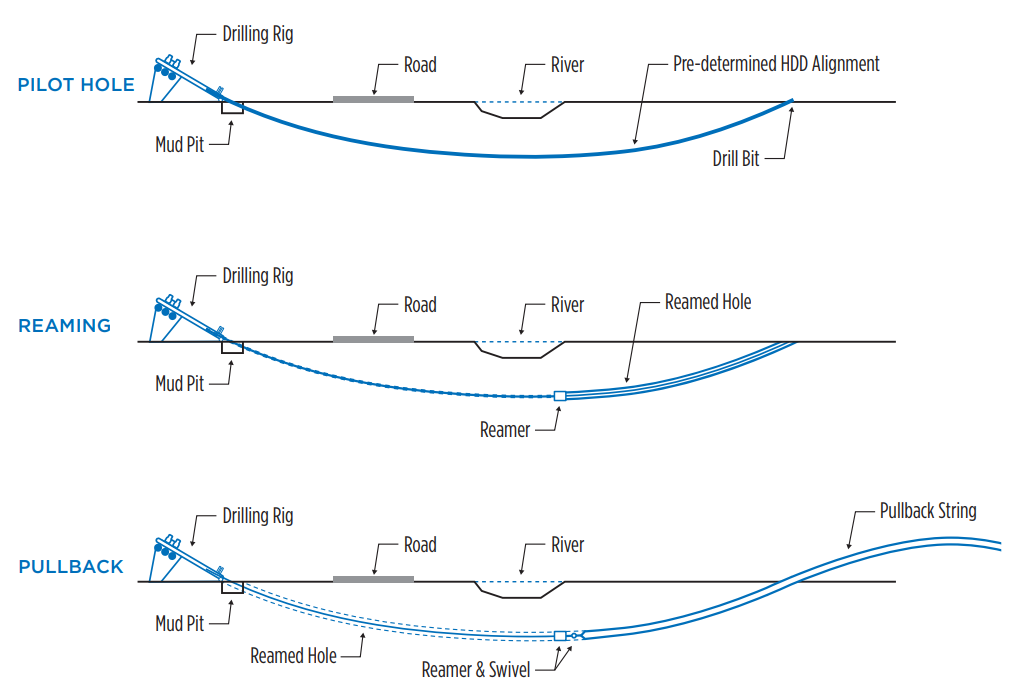

HDD installation is a multistep process:

- Pilot hole: This is the perhaps the most crucial step for successfully installing an HDD crossing. The pilot hole requires drilling along a carefully designed path. The drill bit is monitored and tracked in real time to minimize any deviation from the proposed path and to make adjustments as needed.

- Reaming: The second step consists of employing a tool called reamer to enlarge the pilot hole to a final diameter greater than the product pipe. The type and size of the reamer depends on numerous factors, such as geological formation, drilling mud and product pipe diameter. Typically, an overcut of 12 inches or 1.5 times the diameter of the product pipe is used by the contractors.

- Pullback: The final step in the process entails pulling the product pipe through the reamed borehole, which involves attaching the fabricated pipe string to the drill pipe using a swivel and a pullhead. It is recommended to complete the pullback step without pausing or stopping to avoid the pipe getting stuck within the borehole because of drilling mud settling and solidifying.