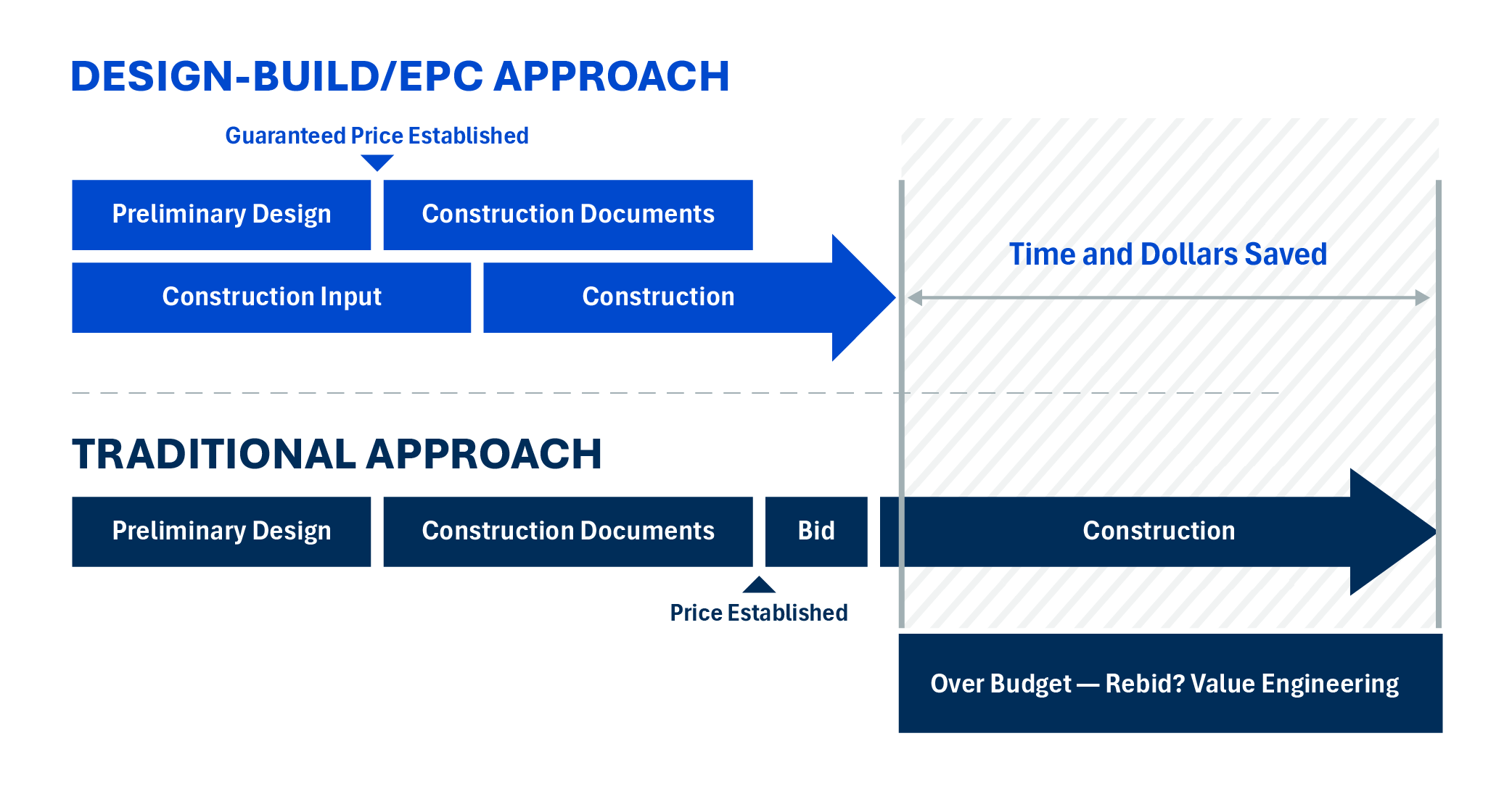

There is a direct correlation between effective planning and predictable project success (scope, schedule, budget). Partnered planning can be used as a “stage and gate” process to gain stakeholder alignment where decision points are identified at critical stages, such as financing and funding, or regulatory approvals and customer commitments, before proceeding. The owner can be involved in key decisions and work with the EPC contractor to determine the technical and commercial impact of project decisions before fully committing.

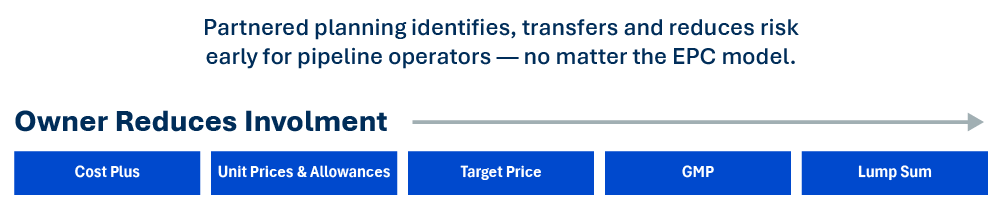

Upfront partnered planning can quickly identify and reduce risk, even if a pipeline project is undefined, with a very preliminary or extremely complex scope. Owners can rest easy that project success is achievable when incorporating comprehensive, innovative, upfront project planning. Partnered planning aligns incentives for both the operator and EPC contractor from the very beginning, allowing for a collaborative and teamed approach for overcoming each project’s unique challenges. While gas pipeline projects, especially within the regulated utility industry, rely on cost transparency, capital spend targets and prudency, at-risk developers may not be motivated in the same way. Developers may have limited staff to manage a partnered planning effort or may even want to have a solid lump sum bid from the very beginning for project financing purposes.

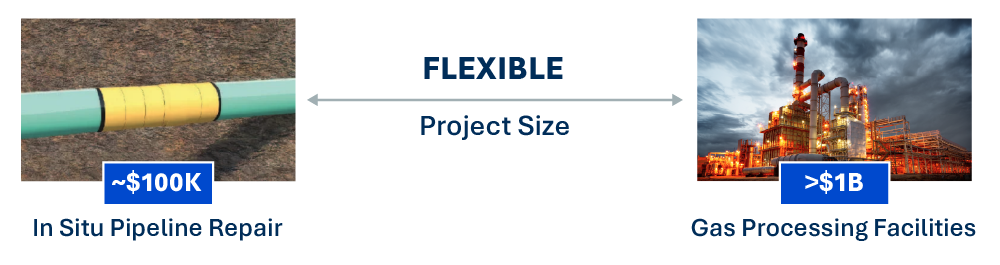

Whatever the motivations of the project owner, EPC is a flexible contracting model that can incorporate partnered planning with as much or as little cost transparency desired.