Recent advancements in understanding the role complex subsurface heterogeneities play in contaminant storage, distribution and transport have led to improved pump-and-treat system designs and optimized, lower cost applications. These improved systems focus groundwater extraction efforts on aquifer zones that are most critical for contamination containment or mass flux reduction. This approach to pump-and-treat remediation has been supported by the advent of high-resolution site characterization (HRSC) tools that produce the type and quantity of data needed to generate quantitative conceptual site models (CSMs) and use groundwater fate and transport modeling tools to optimize system designs while reducing uncertainty.

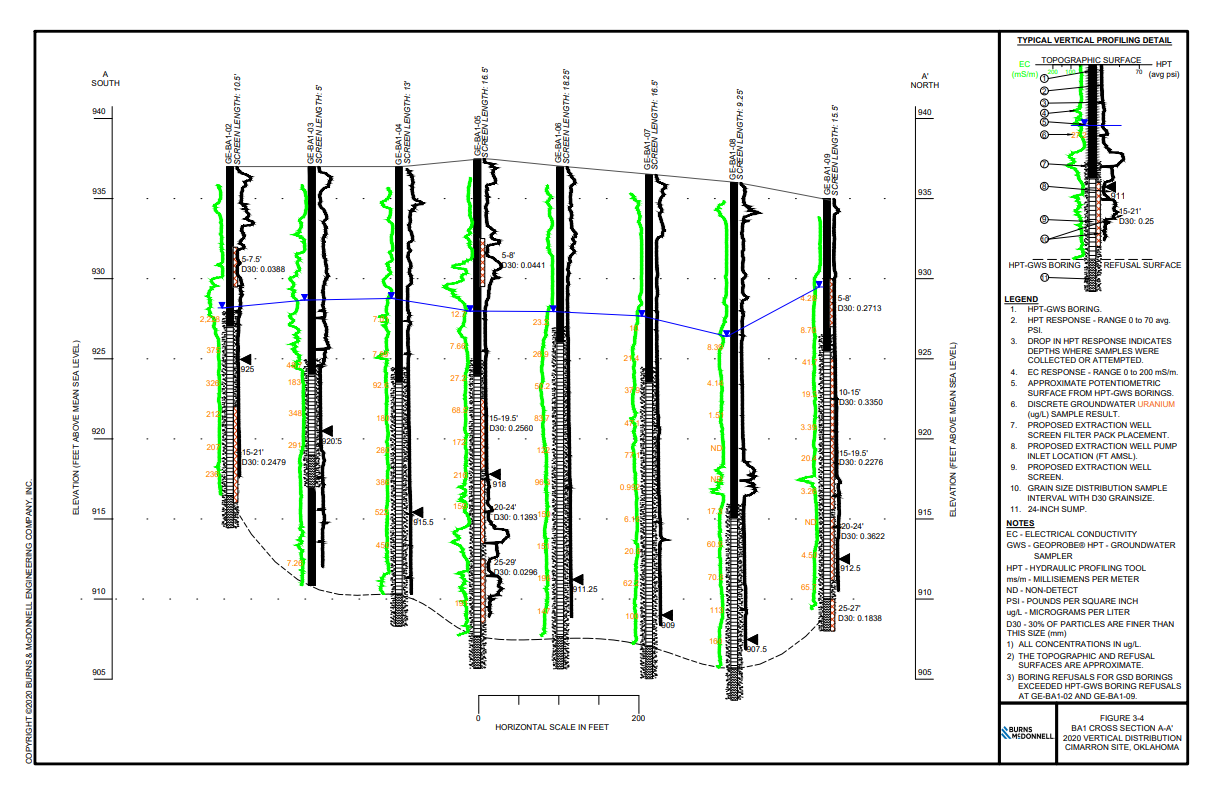

These advanced HRSC and modeling methods were recently applied on a project requiring pump-and-treat remediation, with treated water injection, to address uranium and nitrate groundwater contamination plumes extending over 200 acres and threatening potential human health and ecological receptors. Vertical profiling activities were conducted using depth-discrete groundwater sampling methodology at 23 proposed groundwater extraction well locations to refine the vertical delineation of uranium and nitrate concentrations. In addition, HRSC direct sensing technology was used to assess relative permeability and lithology with depth at each well location. Finally, continuous soil sampling and logging were conducted at select locations to correlate direct sensing results and collect soil samples for grain size distribution (GSD) analysis.

The results of these design investigation efforts were used to target extraction well screens on the saturated zone intervals conveying the greatest contamination mass, as determined by contaminant concentrations and estimated hydraulic conductivity. This design optimization approach maximizes the mass of contaminant removed during groundwater remediation efforts while minimizing the recovery and treatment of minimally contaminated groundwater. This improves operational efficiency and reduces the time required to achieve remediation goals, particularly if zones of relatively low contaminant concentration coincide with zones of higher permeability.

Relative permeability and inferred lithological data were collected at each proposed extraction well location using a hydraulic profiling tool (HPT) and electrical conductivity (EC) direct sensing technologies. The data provided by these tools, along with vertical contaminant profiling data, soil boring log observations and GSD results, were used to select optimal screen intervals and extraction pump intake elevations. The GSD results were also used to finalize extraction well design details, including filter pack gradation and well screen slot size.