Especially for interference between two cathodically protected pipelines, bonding the two assets together is the most common mitigation method. Bonding makes both assets electrically continuous, which provides a safe path for current to flow without causing damage to either asset. The goal of bonding is to return both assets to pre-interference potential levels. To do this, the bond can be connected through a test station and should have a specified resistance to control the amount of current flowing to one asset versus the other. Diodes or reverse current switches also can be used to see that current only flows across the bond in one direction. Once pre-interference potentials are met, maintaining these potentials may require significantly more CP current to protect both assets, especially if either asset is uncoated. It is also important to know that once two assets are bonded, changes in CP levels will affect both assets, and all future surveys for either asset will require synchronized interruption of all rectifiers involved. Bonds also require frequent inspections and can be damaged by AC current fault events or lightning strikes.

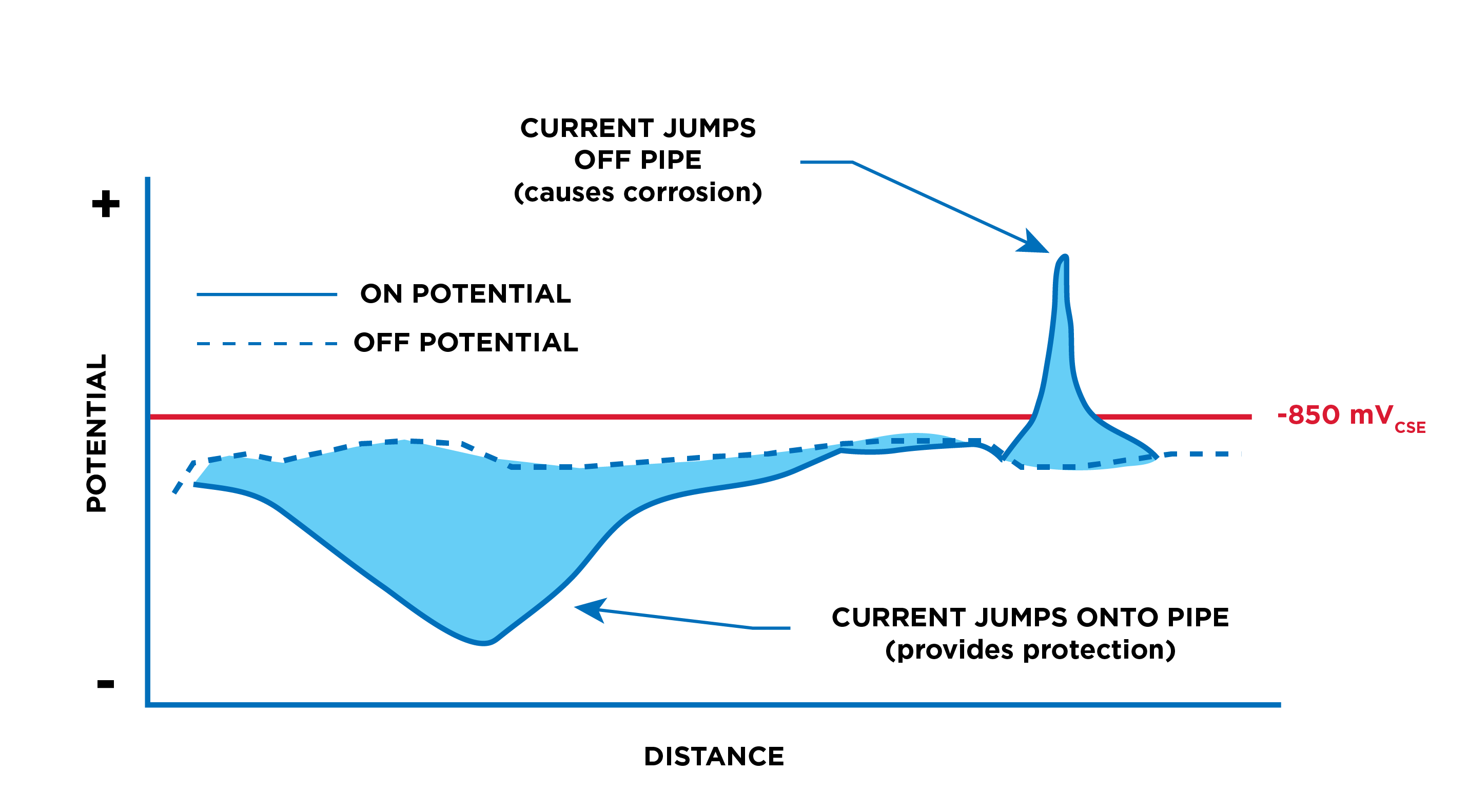

If the interfered-with object is not coated already, coating may offer another mitigation option to prevent current from jumping onto it. If this is the case, be careful to only coat the location where current is jumping on and never coat the location where current is jumping off, because doing so could make the stray current corrosion even worse.

If not already in use, a new CP system can protect the interfered-with asset. In this case the CP should target areas where stray current jumps off the asset. If the stray current has a relatively low magnitude and is localized, installing galvanic anodes may be sufficient to mitigate the problem. A CP system of galvanic anodes is ideal for crossing locations if the interfered-with structure is already coated. In this scenario, the galvanic anodes can provide a safe path for current to discharge while providing additional protection to the interfered-with asset.

If the interfered-with asset is a pipeline, adding more points of isolation along the line may be useful. From an electrical standpoint, this will cut the one long line into multiple shorter lines that are electrically discontinuous, which should result in less significant interference occurring on each section of the pipeline. However, adding isolation is sometimes a complex approach that can become costly. If the asset is protected by a CP system, the isolation will require a new CP source for each electrically discontinuous segment of the asset. This solution should be used with care, as adding isolation may also unintentionally lead to further stray current corrosion around the isolation joint areas.

Installing a metallic shield between the anode and the interfered-with asset has also been used to mitigate DC interference; however, this option is often considered outdated and can easily cause more harm than good. Even if this option successfully mitigates the DC interference, it will likely be more costly than the other options.