The renewable energy industry — primarily wind, solar, hydro, biomass and geothermal — has grown every year since 2015. Moreover, it was the only power generation sector that increased its net share of capacity from 2019 to 2020, according to the U.S. Energy Information Administration (EIA). As generation capacity increases for these renewable solutions, so too does the demand for systems that store this often-intermittent energy. By storing excess energy produced during peak production periods, renewable energy can be made available for longer periods extending into off-peak times.

Batteries have been around since the 1800s, but those capable of cost effectively storing the energy necessary to power a hospital or an entire city are relatively new. One need only look back to 2012, when lithium-ion battery technology was just a U.S. Department of Energy demonstration project to see how far the technology has come. Today, due to a decadelong focus by the electric vehicle industry on lithium-ion battery development and steady drops in production cost, this technology has become a preferred method of energy storage supporting the renewable sector.

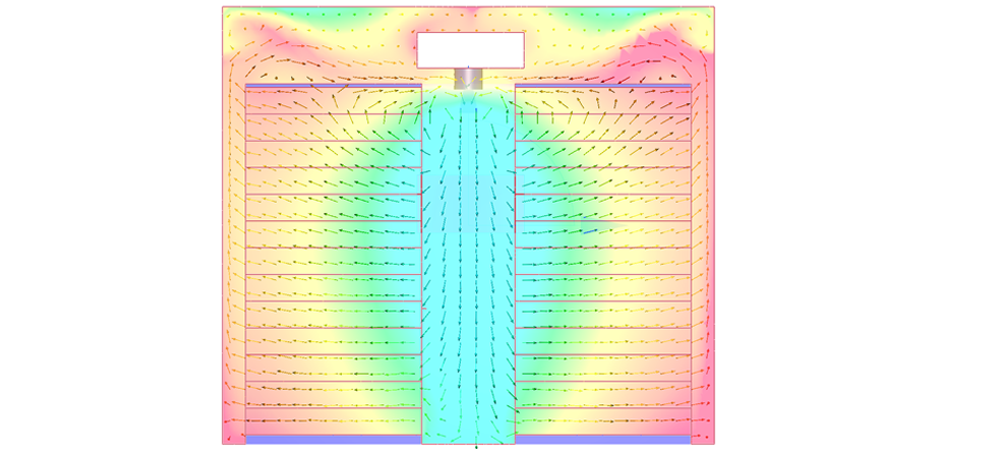

Increasing battery energy storage capacity results in heightened thermal demand required by these systems. In addition, as the energy density of batteries increases, so does heat density. More stringent requirements are then placed on thermal management designs implemented to support the operation and life of these batteries, which typically function in a narrow-preferred temperature range between 65°F and 85°F. Traditional direct expansion (DX) packaged air handling units (AHU) use a condensed refrigerant liquid to produce a cooling effect on the coils in direct contact with the conditioned air. DX units cool batteries inexpensively at the front end of the life cycle, but over time they become increasingly inefficient, resulting in higher energy usage and operations and maintenance (O&M) costs.

An existing technology utilized in many different systems provides another more energy-efficient option. Multiple cooling and heating systems for downtown districts, large college or hospital campuses, and manufacturing facilities rely on central utility plants (CUPs) that employ large centrifugal chillers to distribute chilled water throughout multiple buildings to handle their heat loads. Heat can be exhausted to ambient using evaporative cooling. Other benefits of these systems include the ability to add redundancy to the system to reduce potential downtime. Thermal storage can be used and extra capacity for future loads can be added relatively easily. Centralized cooling for battery storage can be deployed in a similar manner for both containerized or building solutions. This type of system has been proven over years of utilization to be robust and energy efficient, while also making maintenance easier due to centralized centrifugal equipment and a reduced frequency of maintenance activities.