Executing these interconnection projects increasingly takes an integrated engineer-procure-construct (EPC) approach that is centered around reliability planning studies, interconnection queue support, and end-stage operational integration and commissioning. Emerging and quickly evolving technologies make this more crucial than ever.

It's a given that the interconnection queue can be lengthy. Utilities and developers alike need to be aware of many factors, including regional variations of the process, that could affect the ultimate success of an application.

How does one navigate that process appropriately and efficiently to attain project objectives? Time is money, and any unnecessary delays to interconnection can cost months of service, potentially representing the difference between a positive or negative net present value (NPV) for a project as a portfolio asset. That difference could determine whether the project ultimately goes forward.

Here are four tips for navigating the process.

1. Achieve Consistency Across Studies

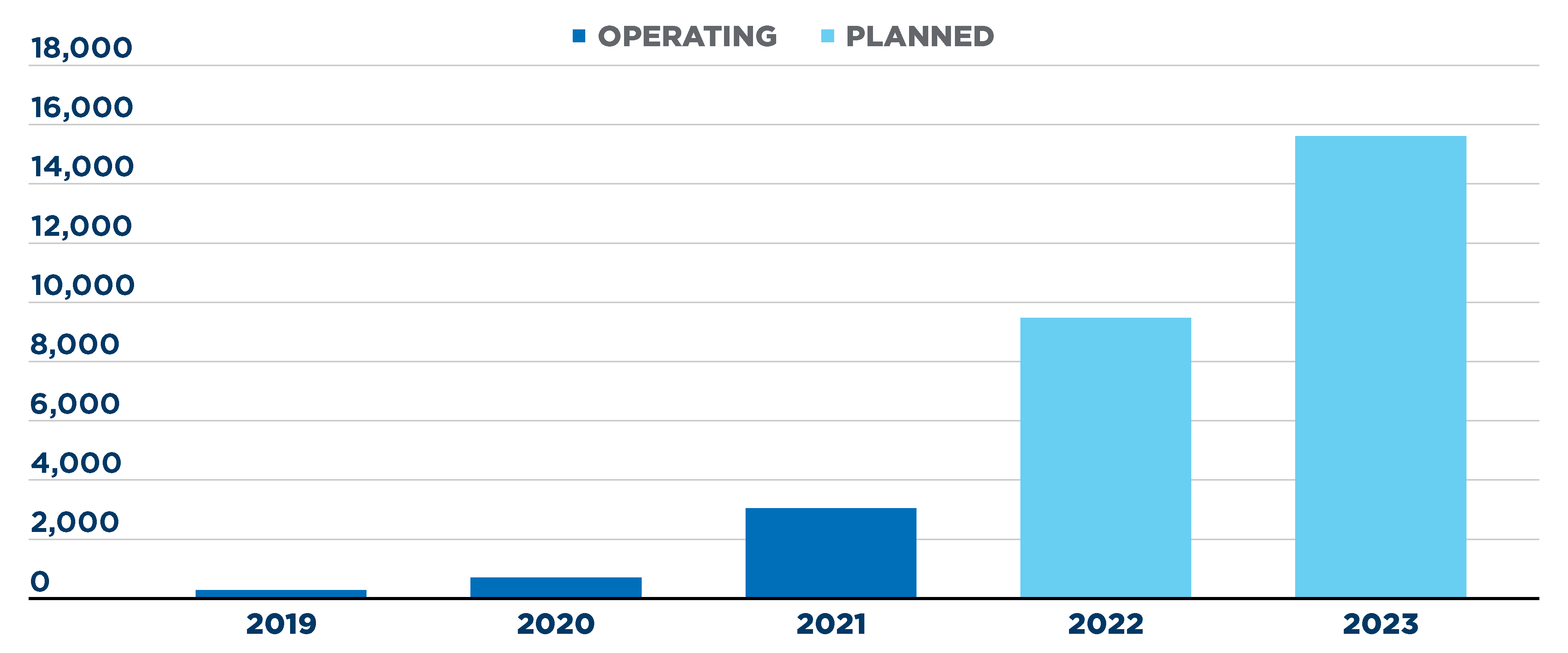

With increasing numbers of renewable and storage projects being proposed and entering development, organizations — from municipalities and quasi-governmental entities to investor-owned utilities — are being saturated with study requests. A utility that performed 20 studies one year might be asked to perform 100 the next while needing to meet the same regulatory time frames.

Significant study areas of focus include:

- Power flow analysis

- Transient stability analysis

- Bus flow analysis for phase I and II of the annual cluster-based interconnection studies

- Subsynchronous resonance studies

- Reactive power assessments

- Model quality testing (PSSE & PSCAD)

Whether assisted, partnered or handled in-house, study consistency is essential to obtaining good results while minimizing demands on valuable time. Evaluators must take all technologies into account and approach each without biases, reflecting the reality that varying technologies come with different challenges and serve different objectives.

2. Adopt Best Practices

Renewables and inverter-based, resource-specific regulations tend to arise in a piecemeal fashion, starting in one region before being adopted in others, like a wave across the industry. EPC partners with a deep bench of qualified regulatory and transmission planning professionals who have knowledge of requirements spanning multiple regions can leverage first-mover experiences in one region to help smooth out the regulatory wrinkles in another. A technology-specific requirement in one region might be new to a given utility, but the integrated EPC partner might have already performed two, three or more studies in regions that already have addressed that regulation.

Drawing on that previous experience can bridge the knowledge gap for the project owner, ISO/RTO, and the utility, enabling the application of standards already established elsewhere to avoid reinventing the wheel and avoid hurdles or pitfalls already successfully navigated elsewhere. Trends tend to move like waves, whether they’re regarding the hosting capacity requirements in one region or offshore wind integration in another. Leveling that industry knowledge base nationally is essential to promoting fast adoption of best practices.

From a developer/owner perspective, best practices can be attempting to standardize project-side details, such as major equipment and layout of inverter blocks. This standardization can help strengthen vendor relationships so owners can stay up to date and ahead of technology changes to minimize project impacts. This standardization can also help the ISO/RTO and TSPs know what to expect when certain entities apply for project studies.

3. Accelerate Through Modularization

Every project has its life cycle, moving from ideation and studies to design, energization and becoming commercially operational. Speed to market is an important driver.

Modularization solutions are an increasingly popular way to speed up project execution, and they can be a sensible choice in many contexts. However, there are caveats. Modular packages and approaches that cost less upfront or work well in one region might not be worthwhile in another if they cannot gain acceptance from governing regulatory bodies. There are differences in modular packages and solutions, so it is prudent to investigate how the preferred option might impact project timing and regulatory filings. Standard designs can be a starting point, but even they can require tailoring to individualized circumstances.

4. Adapt for Differing Penetration

Not all power is equal. For example, some types of inverter technology can add nonstandard power quality into a system. Why is that potentially a problem? Think of the ideal electrical grid as a pool of clean water. When nonstandard power or harmonics are injected into the system, maybe it adds a little salt. If that is just a single, small occurrence — perhaps equivalent to adding a gallon of salt in a 200-gallon pool — it’s not too big of a deal. But what if industry trends lead to 100 new resources, somewhat like adding 100 gallons of salt into that 200-gallon pool? It would make a big difference, and that could lead to technical problems in the system that wouldn’t crop up in the smaller example.

Size, scale and penetration matter tremendously, as does knowledge of the technical nuances of varying technologies. Differing penetration scenarios call for different studies. Utilities may not want or need an advanced set of studies in a small-penetration scenario, but they also would not want to be taken by surprise if the combined effects lead to unforeseen system issues, due to higher penetration trends in certain areas of the system.

It is essential to understand the broader context of a project and see the big picture. In the long run, it is far more economical to build the right system upgrade than to underestimate, make multiple adjustments and wind up with a large system rework. Spending a little more upfront or taking a slightly different approach from the beginning could reap huge future-proofing benefits.