BACKGROUND

ASRS vary widely depending on the type of fulfilment operation. Distribution centers, manufacturing facilities and e-commerce operations have unique challenges, and strategic thinking is required to determine the most appropriate solution for each.

The optimal tools for efficient operations are dictated by product mix, order rate, minimum order quantities and type of fulfilment process, all of which differ by facility. Though you undoubtedly know your own business very well, you may not fully understand how these factors intersect with automation.

Comprehensive analysis, including modeling the appropriate systems design or support systems, provides this insight. First, though, detailed operational data must be developed.

DEVELOPING AND VALIDATING THE DATA

Extensive data validation is essential for the engineering of an effective ASRS. This is both the most complex step in sizing the system and the one that is most often shortchanged. To design an ASRS for your facility, the ASRS vendor will require detailed data about your operations, including:

- Physical data for all products.

- Order data, both historical and projected.

- Required inventory levels.

- SKU velocity classification.

ASRS vendors expect this portion of the project to be provided to them upfront, but often the data simply isn’t available. Frequently, product dimensions are not fully documented and order histories are inaccurate or incomplete.

Required inventory levels and SKU velocity classification methodologies designed for a manual system also must be evaluated to determine their appropriateness for an automated system. Specifically, the data must be modeled to predict the required size and throughput capabilities of the system in the future.

Even when adequate data is available, you may not have the experience or time to review and validate it, let alone present it in a form that can be used by an ASRS vendor. A full-service automation company, on the other hand, will be adept at obtaining this data and performing the predictive analysis necessary to develop the rightsize system.

DESIGNING THE SYSTEM

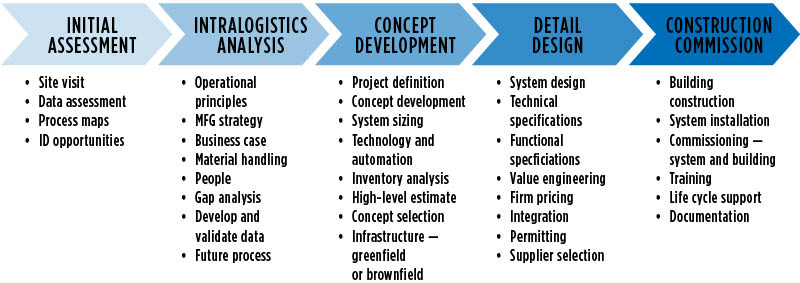

Once the necessary data has been developed, the design process can begin. The first step is defining and assessing the operational objectives and scope of your project. Later stages include equipment selection, integration of packaging and storage with production, building construction analysis, and meeting facility permit requirements.

PROJECT DEFINITION

During project definition, an automation solution provider will develop an accurate understanding of your business, including how services and products are distributed from the fulfilment center. The solution provider will assign a team to measure, analyze and document your current operational processes, as well as physical constraints, product specifications, packaging requirements, and operator safety and ergonomics.

Using verified data models, the solution provider can then establish the parameters for your facility upgrade. Moving from manual to automated systems usually results in a significantly smaller facility footprint, and consolidated operations. Your automation solution provider will be keenly focused on identifying innovations — such as high-density storage, vertical space management and automated equipment — that will introduce efficiencies and cost savings throughout your fulfilment operation.

EQUIPMENT SELECTION

The automation and storage industry is comprised of wide range of companies that offer select systems. While the companies that provide these systems are experienced in integrating across different products, generally they do not evaluate or engineer options outside their own product offerings.

For example, if a company offers automated storage options, automatic guided vehicles (AGVs) and conveyors, those are the products they will engineer for the solution, even if other equipment options would work better or be less expensive. In other words, their approach would give preference to their own products despite the fact that an integrated offering might be the best solution for an application.

Working with a vendor-agnostic solution provider allows your solution to be custom engineered for your facility using the products and systems that work best for each application, regardless of manufacturer.

INTEGRATION OF PACKAGING AND STORAGE WITH PRODUCTION

ASRS vendors tend to focus on evaluating storage options in the distribution system, and this is a crucial aspect of the process. However, engineering the integration between production and the shipping docks is equally important.

There are many factors to consider. Operations for full pallets, mixed pallets, case or single piece fulfillment and kitting operations each have unique attributes. The use of carrier boards, slip sheets, totes and pallets must be evaluated, as well as whether they are captive in the system or introduced at some other point in the process.

While an ASRS vendor may give you several options, some don’t have the internal capability to assess manufacturing processes that affect storage, order fulfillment design or the shipping methodology. By comparison, a fullservice automation provider will determine how the new ASRS will impact the entire fulfillment process, including upstream manufacturing processes and downstream shipping operations. Whenever possible, the solution provider will introduce efficiencies to streamline operations both within and beyond the four walls of the warehouse.

BUILDING CONSTRUCTION ANALYSIS AND PERMITTING

If your ASRS requires a new building or a building modification, you also will need knowledge of and experience with various regulations influencing the project. A qualified automation solution provider can evaluate the available design options and engineer the system to meet relevant codes.

Code compliance and safe operations are critical for complete project success. This is especially true when considering which modifications are needed to incorporate a new storage system within an existing facility. Your solution provider should be able to provide comprehensive return on invested capital (ROIC) analysis, concept design, and engineering of supporting facilities and integrated systems.

A full-service provider also acts as your contractor by providing bidding processes, schedules and budgets for various options and helping you evaluate complete project scope. A turnkey supplier will relieve the burden on your project managers by managing suppliers in disciplines with which he or she is unfamiliar. Additionally, with one supplier in charge, the opportunity for confusion around scope responsibility will be reduced.

DEVELOPING INTEGRATION DOCUMENTS

Once a system concept design is completed, the focus turns to developing the engineering documents for complete facility and systems integration. This is a significant step in successful project execution, and one that requires knowledge and experience in many areas, including:

- Automation hardware systems and control systems validation.

- Software integration with warehouse management (WMS), warehouse control (WCS), warehouse execution (WES) and enterprise resource management (ERP) systems.

- Construction phasing and outage coordination planning with plant operations.

- Traffic planning and coordination during construction.

- Evaluation of facility upgrade requirements.

- Equipment procurement and installation.

- Building codes and regulations.

- Municipal permitting.

Any of these, or a host of other potential risks, can be the cause for delays and unplanned production interruptions when not adequately addressed.

A full-service automation company gives you access to knowledge and experience in each of these disciplines under a single contract. This helps identify and resolve all potential issues as early as possible, which in turn supports critical path schedule management and avoids fingerpointing when something goes wrong.

IMPLEMENTING THE ASRS

The implementation phase requires close coordination between all parties to complete the project on time and within budget. Your automation provider will oversee the entire process for you, including:

- Managing all vendors and construction subcontractors.

- Working closely with plant management and operations to build the solution.

- Monitoring daily activity to avoid interruptions to production and warehouse operations.

Once your new ASRS is online, your solution provider will offer training on the new system so you can begin benefiting from increased efficiencies immediately.

CONCLUSION

Working with a full-service automation solution provider offers many benefits. First and foremost, your custom solution will be designed to optimize your specific processes and facilities. Engineering and procurement will be integrated to reduce cost and improve outcomes, and construction will be phased to maintain ongoing operations.

Having ready access to professionals from a variety of related disciplines reduces coordination effort, raises team awareness of project milestones and facilitates on-time delivery of your new ASRS. In addition, using a designbuild process typically shortens the project schedule and reduces overall project costs. Ultimately, comprehensive execution improves both customer satisfaction and the bottom line.

YOUR CUSTOM ASRS

A custom solution should include the combination of products that is most appropriate for your application, regardless of manufacturer. A fullservice automation solution provider will weigh all of the options, including:

- Unit load ASRS crane vs. UL shuttle system.

- Mini-load ASRS crane vs. shuttle-based system.

- AGVs vs. manual transportation or conveyor.

- Manual vs. automated picking.

- Automated palletizing: standard vs. robotic.

- Automated unit load handling: pallet conveyor vs. inverted monorail shuttle vs. AGVs.