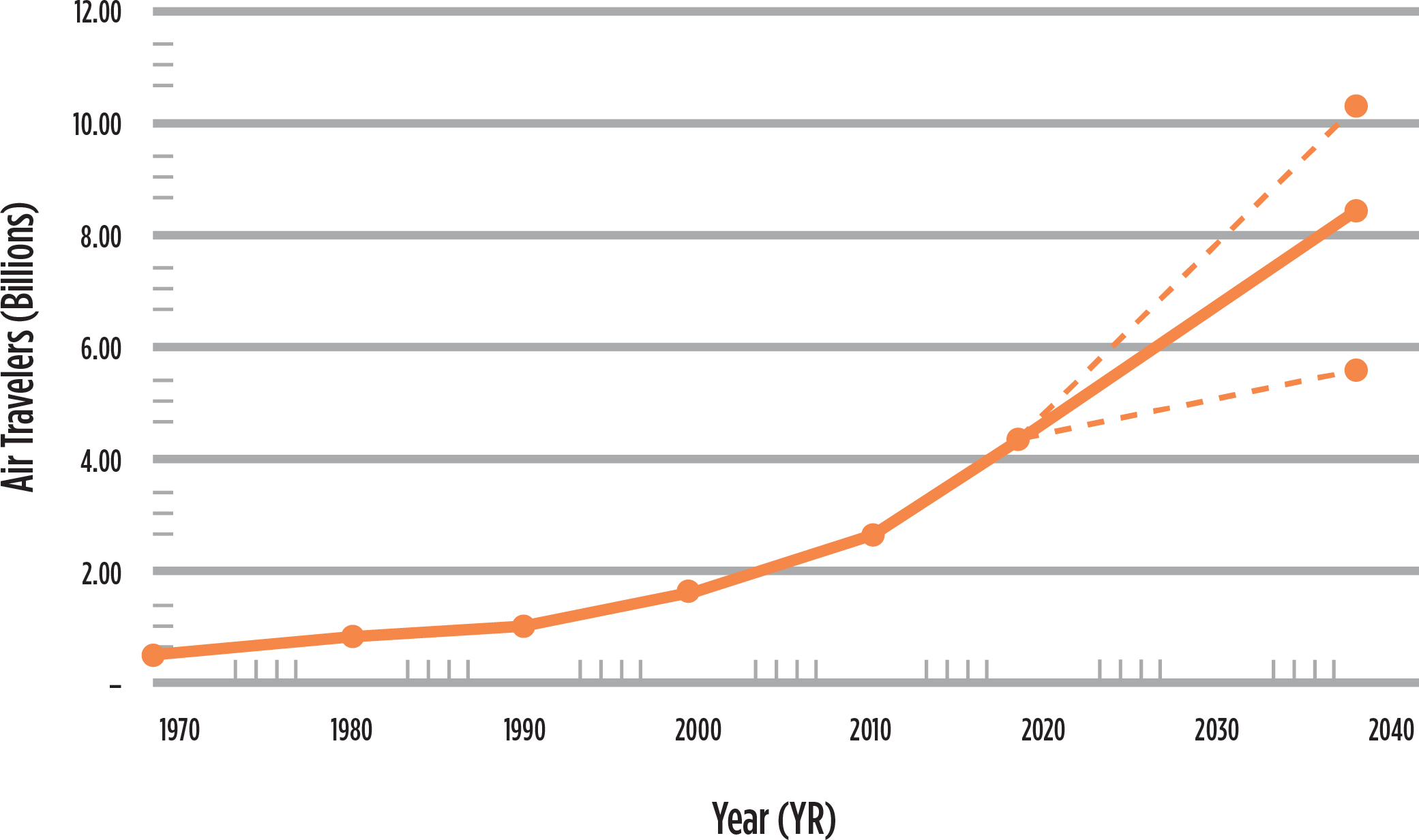

Air traffic has increased dramatically, and the trend shows no signs of stopping; the International Air Transport Association suggests passenger numbers could double to 8.2 billion by 2037. This growth has placed a significant burden on airport pavement, subjecting it to greater loads. Maintaining aging and deteriorating pavement networks has required more effort — and more budget — every year.

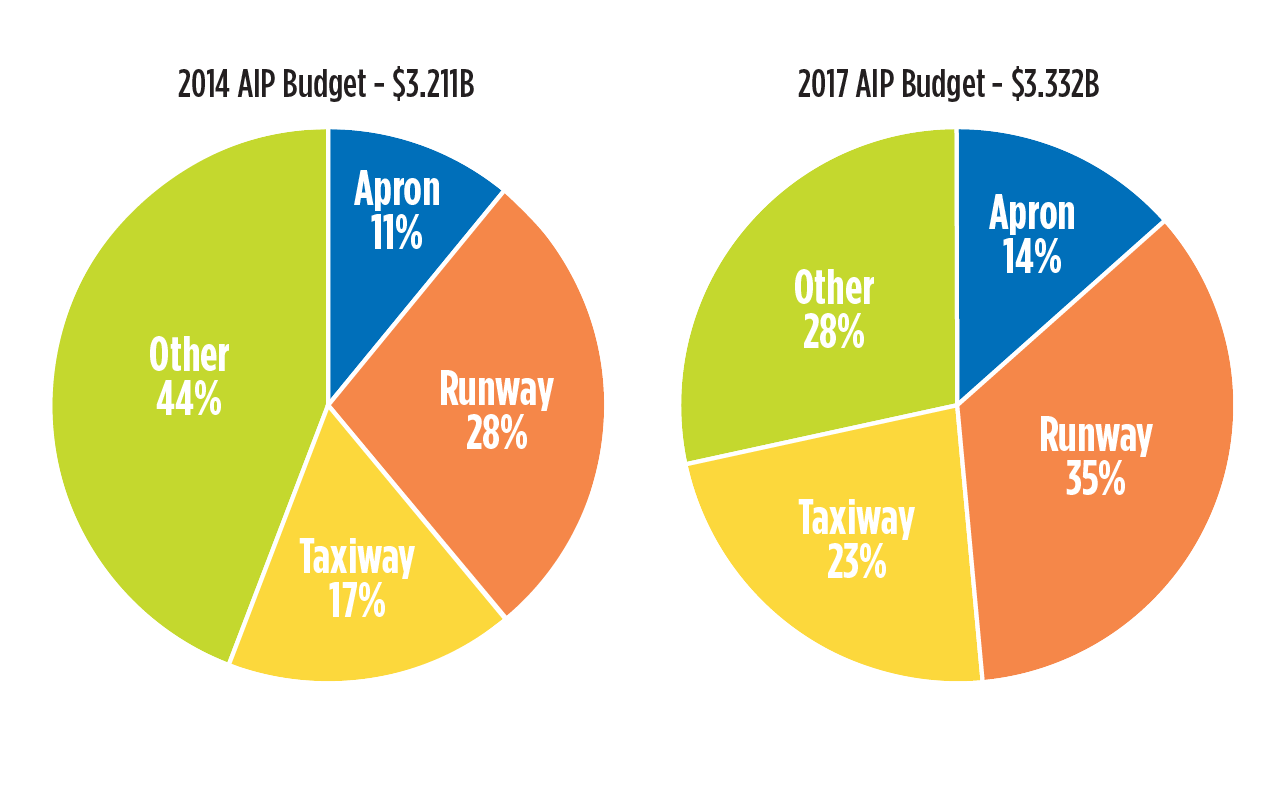

Nearly $2.4 billion was spent on apron, taxiway and runway type projects in 2017, according to the February 2019 Airport Improvement Program (AIP) Fiscal Year Report to Congress. That represents about 72% of the overall AIP annual budget, an increase from the 56% spent on similar projects in 2014.

Identifying ways to optimize pavement design and effectively manage pavement infrastructure assets is more important than ever — and there’s an improved way to address this challenge.

AN IMPROVED APPROACH

Pavement zoning that results in variable cross section designs is nothing new, but traditional approaches have typically generated debate about cost-benefit and constructability. Finding ways to cost-effectively optimize zoning demands a greater design emphasis. Establishing an extensive library of actual airside loading conditions to evaluate various required designs can lead to more precise zoning alternatives.

As owners move toward innovative collaborative project delivery methods, this approach allows designers and builders to collaborate over a variety of design alternatives. The result is more precise and strategic designs, producing a cost-effective pavement section that reduces the project budget.

DRAWBACKS OF TRADITIONAL PAVEMENT DESIGN

Though pavement is an essential element of airfield design, it traditionally hasn’t demanded much individualized attention. Engineers primarily use two types of software to evaluate the thickness of airport pavements:

- PCASE (Pavement-Transportation Computer Assisted Structural Engineering), the standard U.S. Army Corps of Engineers software.

- FAARFIELD (FAA Rigid and Flexible Iterative Elastic Layered Design), the standard Federal Aviation Administration (FAA) software.

Figure 1: IATA 2037 Air Travelers Forecast. Source: International Air Transport Association Forecast

While both are valuable tools, the generality of their use and application can lead to a design that’s more conservative and generic than precise.

While PCASE and FAARFIELD can handle complex gear configurations for large and military aircraft, its models currently only access a standard library of aircraft main gears — which carry about 95% of an aircraft’s load during ground operations — and a limited number of ground support equipment. Both programs allow customization, though engineers typically identify a general fleet mix for the airside area and follow a defined process within PCASE and FAARFIELD based on this standard library. The software generates a suggested thickness, which is typically applied to generalized areas or, at times, the entire pavement infrastructure.

But this basic approach can lead to overdesigned pavement networks. Because the main gear is located midway under an aircraft, much of an airside pavement infrastructure may never experience the loading conditions more generic pavement design demands. Additionally, limited nonairplane vehicles may not accurately represent loading conditions of the ground support equipment or other support structures, such as passenger boarding bridges.

For example, the extended area surrounding every terminal facility only needs to support the load carried by the aircraft’s nose gear, ground support equipment and passenger boarding bridges defined by the specific gate design. Or, an airside area may only need to accommodate specific airplane design groups (ADG) based on the geometric layout and setback dimensions.

Instead of applying the same pavement thickness everywhere, accurately modeling the imposed loading conditions on various airside pavement locations can lead to precise, load-specific pavement zoning. It’s an improved, innovative approach — backed by a detailed methodology — that can provide accurate and reduce the conservatism of generalized design.

AN IMPROVED METHODOLOGY

Generating pavement thickness design calculations around a set of input parameters — including FAA traffic count data, ADG information, airport engineering, pavement use and actual gear configuration loading conditions — offers a new and strategic way to utilize PCASE and FAARFIELD. These parameters establish pavement zones that, in combination with the main gear configuration data the software already offers, form the basis for more precise pavement thickness design calculations.

Figure 2: FAA AIP Project Type Funding

This methodology provides designers and owners with the most relevant information available. The pavement zones can serve as a foundation for design plans that range from probabilistic to worst case, fulfilling current needs and allowing flexibility for future growth.

Pavement zones are determined using traffic count data, airfield operations and an extensive external library of aircraft nose gear, passenger boarding bridge equipment and ground support equipment configurations. This has extended the design process to include:

- Consulting manufacturers to accurately model loading conditions for nose gear, passenger boarding bridges and ground support equipment.

- Establishing additional gear configurations in PCASE and FAARFIELD that evaluate unique loading requirements to include nose gear, passenger boarding bridges and ground support equipment.

- Analyzing airside geometric layout for safety area and setback requirements to evaluate potential pavement zoning alternatives based on ADG.

- Categorizing aircraft per ADG classification.

- Utilizing FAA Traffic Flow Management System Counts (TFMSC) reports to determine common ADG classes III, IV, V and VI, and the probability of specific aircraft traffic.

- Reviewing traffic patterns — including turns per gate per day, wander patterns and pass-to-coverage ratios — to better analyze specific load conditions.

- Establishing specific fleet mixes and coverages per pavement zone, then running various designs to establish pavement zoning alternatives.

- Backchecking all designs against passenger boarding bridges and ground support equipment operating in the area.

- Performing paving material quantity takeoffs and a cost-benefit analysis of all pavement zoning alternatives, and then evaluating each with all stakeholders and contractors.

- Encouraging collaborative design to create cost-effective alternatives that offer flexibility for future growth.

OPTIMIZING EFFICIENCY THROUGH COLLABORATIVE PROJECT DELIVERY

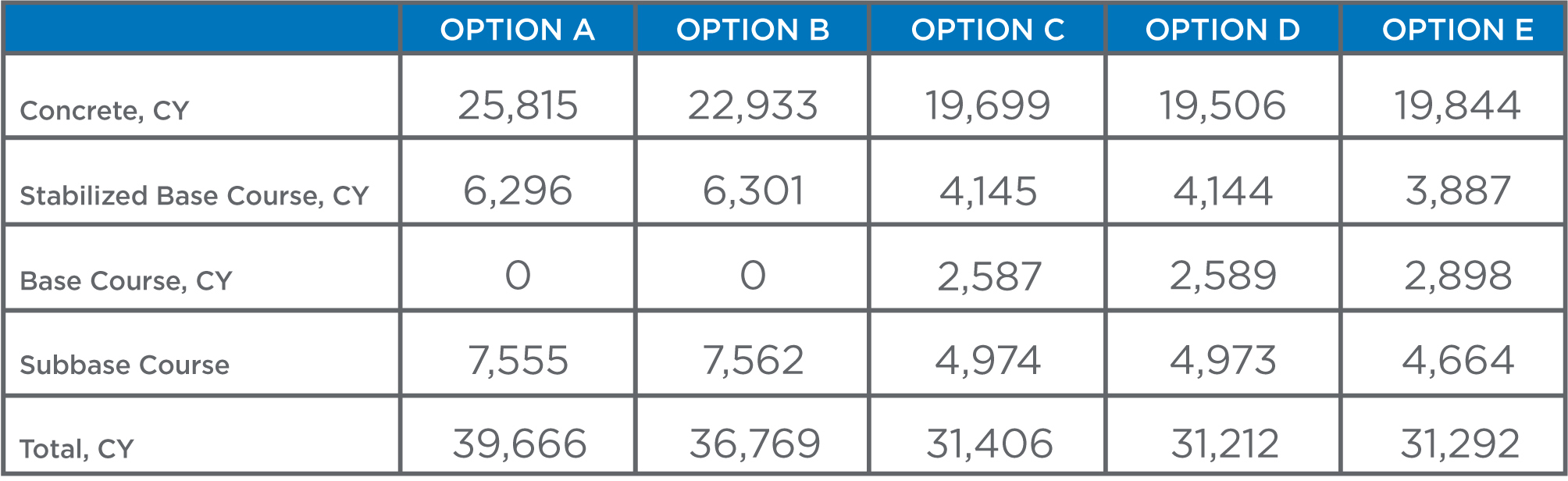

This approach represents a paradigm shift in pavement design: precision over generalization. Simply put, it will require fewer paving materials — at times, dramatically less — and lead to cost savings. For example, optimizing the zoning layout of 400,000 square feet of airside apron pavement can potentially result in a reduction of more than 8,000 cubic yards of paving materials based on alternative analysis.

While this methodology may result in a more complicated build, a cost-benefit analysis of the pavement’s life cycle can quantify the benefits of the enhanced design.

Figure 3: Pavement Material Quantities

Optimized pavement design provides benefits beyond reduced capital costs. Since each pavement area is designed based on the specific impacts and stressors it’s likely to receive, the entire pavement network will wear more consistently, leading to more effective rehabilitation and maintenance programs. And since the configurations can be based on the maximum potential load, this approach offers flexibility for any airport, even accommodating tenant changes among airline carriers.

In a time when air traffic continues to increase and pavement projects consume more of the total improvement budget, every progression in efficiency makes a serious impact. Optimized pavement design plans that provide precise pavement zoning layouts — in concert with collaborative project delivery methods — equip owners to make the most of their constrained budgets. The result is cost savings and improved techniques to better manage the demands and complexities of future projects.