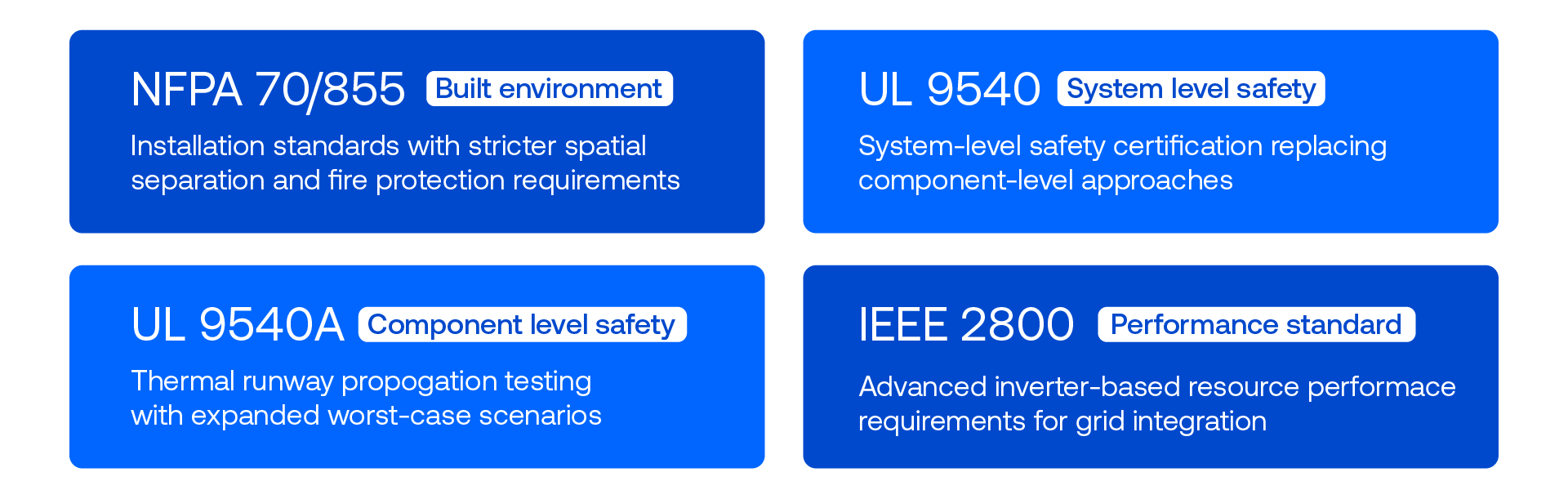

As the deployment of BESS installations accelerates, safety and interoperability standards are evolving rapidly to address emerging risks and operational complexities. Updates to key energy storage system codes and safety standards, particularly NFPA 855, UL 9540, UL 9540A and the expanding adoption of IEEE 2800, is reshaping the landscape for system developers, integrators and asset owners. While these standards are critical for safety, reliability and grid integration, they also pose challenges that must be carefully navigated to enable scalable and cost-effective BESS deployment.

NFPA 855, the Standard for the Installation of Stationary Energy Storage Systems, is increasingly being incorporated into adopted local Codes and Standards across the United States. However, one challenge can be variability in interpretation by authorities having jurisdiction (AHJ), who retain broad discretion in enforcement. Inconsistent application of NFPA 855 across municipalities can lead to unpredictable permitting timelines and redesigning cycles that increase both cost and risk.

UL 9540, the Standard for Safety of Energy Storage Systems and Equipment, has undergone recent revisions that place a stronger emphasis on system-level safety rather than just component-level certification. Manufacturers who previously certified individual components must now demonstrate the integrated system’s ability to perform safely under a wide range of fault conditions. This more holistic approach to safety is essential and ultimately leads to greater certainty of outcomes for project executions, but in the near-term results in additional challenges for OEMs seeking to release new products or determining whether to recertify existing products. It is critical for projects moving forward that execution teams understand that the International Fire Code (IFC), NFPA 855 and NFPA 70 (the National Electric Code) require energy storage systems to be listed, and that UL 9540 is the listing standard applicable. Closely linked to UL 9540 is UL 9540A, the Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems. This test method is essential for understanding a BESS’s behavior under thermal abuse conditions. Recent updates to UL 9540A protocols include expanded worst-case testing scenarios, such as initiating multiple cells, testing damaged modules or simulating compromised enclosures.

UL 9540A by design does not provide a clear pass/fail metric; instead, these results generate data that must be interpreted by AHJ and fire safety consultants. The lack of a standardized interpretation framework leads to variable outcomes depending on local jurisdictional preferences, complicating project planning. Additionally, the cost and duration of conducting full-scale UL 9540A tests adds a significant cost — often exceeding hundreds of thousands of dollars — which can be prohibitive especially for smaller developers or novel battery chemistries. Revisions are underway to UL 9540A to define the expectations for large-scale fire testing. This test aims to replicate worst-case scenarios, such as full thermal runaway propagation within a battery rack, and evaluate the effectiveness of fire barriers, suppression systems and overall system resilience. Large-scale testing typically involves initiating failure using techniques such as overcharging, external heating or nail penetration, then observing system response in terms of temperature rise, gas generation, flame propagation and structural integrity. The outcomes of these tests provide actionable insights into how fire spreads within a system, the time frames involved and whether mitigation strategies effectively contain the incident.

IEEE 2800 defines the performance requirements for inverter-based resources (IBRs) connected to the bulk electric system. BESS assets are expected to provide grid services, including voltage regulation, ride-through capabilities, frequency response and support during system disturbances. Meeting these performance benchmarks requires advanced inverter technology and sophisticated control algorithms.

Validating IEEE 2800 compliance requires more sophisticated modeling and simulation, as well as additional commissioning steps, which must be considered when developing project timelines and commissioning plans.

The evolving standards have significantly improved the reliability and safety of BESS installations but require more understanding and coordination for correct implementation. Successful navigation of regulatory requirements for a given jurisdiction requires a proactive compliance strategy, careful selection of technology and system design, and early engagement with engineering and safety specialists. Regulatory standards at a glance are outlined in (Figure 2).