Big Data, the internet of things, Factory 4.0. There’s no shortage of jargon relating to current data trends. Essentially, though, all of these terms refer to the use of data to make better objective decisions.

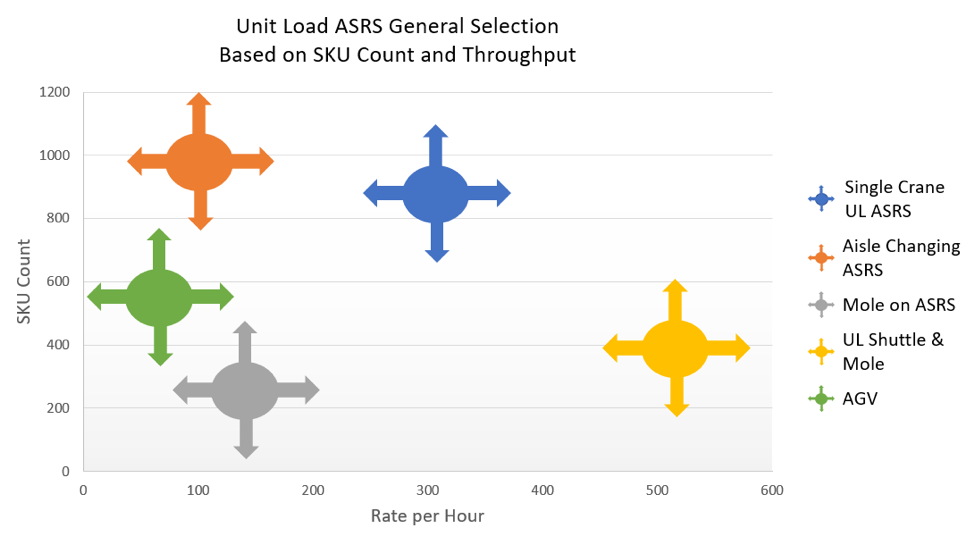

Today, data-driven decision-making is used in industries ranging from retail and banking to healthcare and manufacturing. While it is often most closely associated with increasing sales and revenue, it is equally relevant for the design of automated systems in both manufacturing facilities and warehouses. Specifically, historical and operational data should drive the design of every automated storage and retrieval system (ASRS).

On warehouse automation projects, “We need data” is a common refrain. But it is less clear how data actually leads the design of the system. This paper will provide a general overview of how data drives ASRS design, although each technology supplier or integrator will use its own design methodologies and conduct a deeper assessment into the variables that affect the successful design of individual systems.

Interested in learning more?

.png?width=175&name=azco-white-logo-2020%20(1).png)