Developing Strategic Solutions for DOE Project Delivery

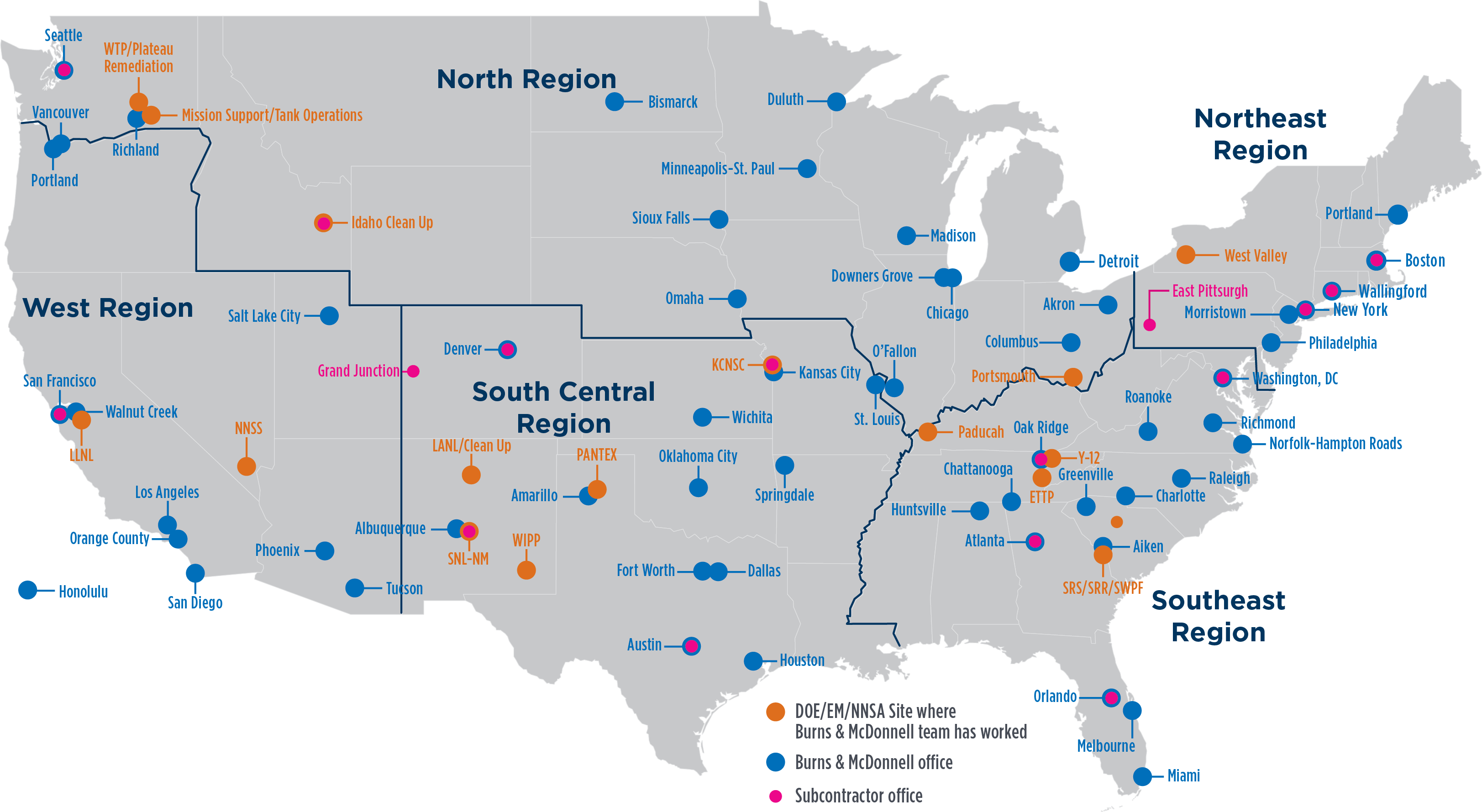

Department of Energy (DOE) sites around the country have significant infrastructure needs to support their growing mission. Utilizing the new Supply Chain Management Center (SCMC) contract vehicle, Burns & McDonnell is ready to support with more than 8,600 in-house design and construction professionals and industry-leading DOE project experience. From designing and building one-of-a-kind critical facilities to managing programs for secure facility operations and campus relocations, we are well-equipped and ready to support the DOE in continuing to protect our nation’s critical nuclear security missions, cleaning up environmental legacy sites, and supporting cutting edge scientific discoveries.

Contact us below to learn how your site can access the SCMC agreement and about our capabilities.

About Burns & McDonnell

Planning and Programming

Infrastructure and Building Systems

Civil, Site and Transportation

Office, Lab, Manufacturing and Support Structures

Environmental Services

Construction Services

The Burns & McDonnell Difference

About Burns & McDonnell

For roughly 60 years, our 125-year-old firm has worked with the DOE to deliver successful architecture, engineering and construction projects, including work with the NNSA since its inception in 2000. Burns & McDonnell is a family of companies that brings together an unmatched team of 8,600 engineers, construction professionals, architects, planners, technologists and scientists to design and build our critical infrastructure. With an integrated construction and design mindset, we offer full-service capabilities with more than 60 offices globally.

#8

in Top 100 Design-Build Firms (ENR 2025)

#3

in Government Office Design Firms (ENR 2025)

#12

in Manufacturing Design Firms (ENR 2025)

Safety by Design

The DOE’s safety culture is aligned with our safety culture, focused on implementing engineering practices that design safe solutions to protect the health, safety and welfare of people after facilities are constructed. Our teams demonstrate that commitment with everyday activities like safety moments and pre-task analysis as well as with unique approaches to safety in design, including virtual reality walk-throughs that allow users to identify operational safety concerns.

As part of our proven corporate policies and procedures, Burns & McDonnell implements a QA process that has been successfully used for the past 25 years. The process based on published guidelines has been endorsed by the American Institute of Architects and the American Council of Engineering Companies. Depending on a specific site’s needs, we can implement our corporate Quality Management System and our NQA-1 program, which is the Federal Quality Assurance Plan and is structured to provide quality, increase value and lower construction risk. Burns & McDonnell is an approved NQA-1 supplier.

The Burns & McDonnell Team

Our team is structured to provide sites with responsive teams who understand local needs and design requirements to deliver consistency throughout the SCMC agreement. In addition to an in-house team of professionals, our qualified subcontractors, including small and disadvantaged businesses, support specialty scope services. These partners have significant experience supporting the DOE EM, NNSA, and Office of Science sites and are firms that we have successfully worked with in the past on similar projects.

Our Teaming Partners Include:

Avant Acoustics

Brierley Associates

Cabrera Services

Commdex

Costantino & Associates

Crawford Consulting Services

Drummond Carpenter

J.G. Management Systems

John Gallup & Associates

Los Alamos Technical Associates

Louviere, Stratton & Yokel

MS Technology

North Wind Group

ONIX

PCS & MOCA JV

Protection Engineering Consultants

RMW

Shannon & Wilson

Sigma Science

Simpson Gumpertz & Heger

Studio 08 Consultants

Walsh Engineering Services

Planning and Programming

With more than 50 years of experience in sitewide planning and programming for DOE and federal facilities and campuses — including maintenance, general plant and capital asset projects — we can support your efforts in advancing energy research, maintaining nuclear security, and fortifying science and technology nationwide.

Our planning and programming services include performing initial studies of space utilization, project feasibility, traffic and parking impacts, preliminary hazards analysis, existing building and site condition assessment, benchmarking, sustainable design initiatives, and development of phased implementation plans for renovation and new construction. We provide strategic and capital planning, along with space planning and design activities, to support the decision-making process for the site. For the DOE, we have performed comprehensive planning services at multiple locations, including the Kansas City National Security Campus.

Case Study: KCNSC Relocation Two-Phase Master Planning

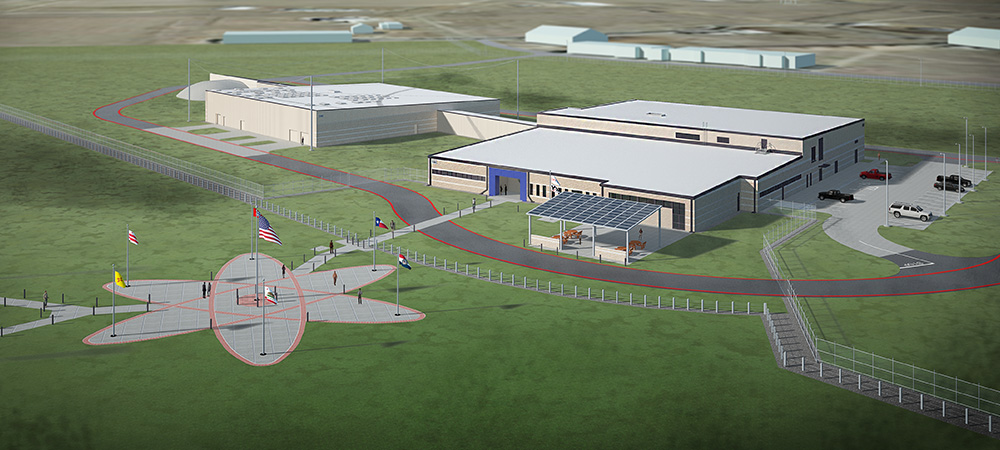

After many years, it was time for the KC National Security Campus (KCNSC) to modernize its operations, which began with the creation of two master plans: a campus master plan (CMP) to support facility consolidation, design and construction; and a relocation master plan (RMP) for the subsequent relocation of all operations, equipment and personnel from the existing plant to the new KCNSC.

The CMP was developed through organized collaboration with campus stakeholders — a process that also required benchmarking and development of long-term customer strategy, operational vision and branding; incorporation of constructability recommendations; and, ultimately, balancing of final Program of Requirements (POR) against the available budget, functional and operating requirements for the DOE and National Nuclear Security Administration.

As part of the campus conceptual planning, the analysis of alternatives process was used to review multiple sites, analyze facility options and recommend a new greenfield site. For the POR, a land use strategy was developed, including conceptual building layouts and exterior elements such as pedestrian and vehicular circulation and parking.

After the CMP was finalized, our team developed the public-private partnership design-build request for proposal and supported the technical aspects and selection process for the bid evaluation during procurement.

Infrastructure and Building Systems

With utility systems across DOE’s Office of Environmental Management and the National Nuclear Security Administration (NNSA) reaching the end of their useful lives, the need for new infrastructure design and upgrades is overwhelming. Growing environmental constraints and unique site conditions add to these complex challenges. Our team offers cross-industry, nationally recognized experience with the design of utility infrastructure, wastewater and stormwater, and building electrical and mechanical systems.

Case Study: NNSA Cooling and Heating Asset Management Program

As the integrated design-build firm, Burns & McDonnell is managing and designing for the $140 million HVAC modernization of DOE facilities across the country. Concerned with degrading facilities and energy efficiency, NNSA retained us to lead the design and construction management of its nationwide HVAC renovation program. This asset management program requires strategic investments in infrastructure systems to reduce deferred maintenance and to increase sustainability and safety.

The repair, replacement and modernization of HVAC systems occurred at similar facility types, including office, manufacturing and support facilities. Our multidiscipline team concentrated on electrical and power utilities; water, wastewater and stormwater; building mechanical and electrical systems; and civil, site work and transportation design considerations. As a result, each HVAC assessment had to account for unique facilities and their highly secure installation requirements.

Since May 2017, Burns & McDonnell has successfully completed more than 100 design and construction task orders, each for projects with a total cost ranging from $1 million to $7 million. Many projects were completed simultaneously using our design and construction resources throughout the NNSA enterprise as well as some of the same subcontractors we are proposing to utilize for this supply chain management center agreement for construction cost estimates.

While the design of modern HVAC systems was the primary focus for the NNSA, electrical, civil and architectural design components also were vital to project success. Additionally, we provided modeling of mechanical and architectural systems, including the building envelope, to determine life cycle cost and energy consumption for comparison.

Civil, Site and Transportation

Civil, site and transportation components of projects establish a solid foundation for successful project delivery, from facility siting to long-term functionality of a facility and site. Our industry professionals have years of experience designing roads, parking lots, site utilities, site grading, stormwater management systems, bridges and pedestrian walkways.

Beginning with the planning process, we offer feasibility studies, detailed design, scenario planning, project prioritization and long-range planning to meet potential growth in usage. Our well-established team can design the entire civil, site and transportation scope anticipated for the Supply Chain Management Center (SCMC) agreement.

Case Study: Sandia National Laboratories-New Mexico Transportation Project

To improve safety and installation security and decrease traffic congestion, NNSA executed a GPP with us to relocate the intersection of 20th Street and G Avenue. Utilizing extensive planning with robust design charrettes, the team evaluated six signalized alternatives and two roundabout alternatives for upgrades.

The preferred alternative was taken through detailed design, with our team also providing construction services. The scope incorporated traffic signals meeting Manual of Uniform Traffic Control Devices standards, with low-emitting diodes heads aligned with lane configurations; new street lighting with signal mast arms; and pedestrian crossings and ramps meeting current Proposed Public Rights-of-Way Accessibility Guidelines standards. Additional services included capacity analysis, value engineering, stormwater design, and coordination of utility locations.

The project received an NNSA NA-50 Award of Excellence.

Office, Lab, Manufacturing and Support Structures

An integrated approach to facility design engages in-house resources to deliver well-coordinated designs that reduce the risk of costly construction change orders. With a 20-year history of manufacturing and support structure design services for the KCNSC, our project portfolio includes more than 400 new and renovated laboratories.

Case Study: Office and Laboratory Line-Item Project for a High Explosive Science and Engineering Facility

Burns & McDonnell served as the prime architecture and engineering partner for the $78 million High Explosive Science and Engineering Facility at the Pantex plant. Comprising three primary structures with interconnecting ramps, the 75,382-square-foot facility features a high explosive material lab building, a technology development/administration building, and a material staging/storage building. The lab and material storage facilities are planned to be hardened structures.

Our architectural and engineering services began with conducting a design charrette and team partnering meeting; performing all required fieldwork to validate existing site information and process equipment; building structural, mechanical and fire protection sprinkler systems; and organizing electrical systems information. Within the overall scope, infrastructure and facility design included 30%, 60% and 90% design submittal. We also developed the design (analysis) basis document containing general project information and calculations and developed construction cost estimates. Construction-phase services covered the construction schedule, preconstruction meeting services and submittal reviews and responses to requests for information. Our team spent time servicing the building through warranty and project close-out.

The mechanical design supported plumbing, utility, HVAC and lab exhaust systems based on life cycle cost analysis, with all plumbing and HVAC systems being designed for LEED Gold certification. Facility control systems are designed to communicate with the typical Pantex site control system. New electrical and communication services support the facility systems and new and relocated process equipment, along with a new, dedicated, uninterruptable power supply. The facility is designed to be protected by a lightning protection system in accordance with DOE-STD-1212 and Pantex standards. Structural design complies with required seismic criteria DOE-STD-1020-2012 (Natural Phenomena Hazards Analysis and Design Criteria) and ANSI ANS 2.26 2004.

Environmental Services

Federal clients require full-service capabilities that can be delivered effectively by in-house environmental consulting and specialty subcontractors with experience in permitting, designing and building projects that meet comprehensive needs. Our team is well suited to manage a site’s environmental requirements, including compliance and remediation services, throughout an asset’s life cycle.

Case Study: Federal Solid Waste Management Project

Naval Station Guantanamo Bay has 24 primary solid waste streams, most of which are regulated by noncompliant management and disposal practices. To help our longtime client, we provided continuation of a feasibility analysis of potential engineering solutions that would result in full compliance with the Overseas Environmental Baseline Guidance Document (OEBGD), the governing regulation for environmental management, for its solid waste streams.

The primary solid waste solution included design and construction of an 11-acre lined landfill with enhanced waste sorting and volume reduction to support long-term operations. This will replace current solid waste combustion practices via air curtain incinerators. Other improvements include design and construction of a state-of-the-art sorting and recycling center, wastewater treatment facilities, construction/demolition and asbestos landfill improvements, and supporting utilities infrastructure.

We verified the existing conditions of the solid waste streams as well as the regulatory deficiencies associated with current management and disposal practices, then developed a detailed site plan for all proposed design components. Additionally, we conducted extensive geotechnical investigations to identify soil conditions for future structures, solid waste facilities and roadways; developed detailed design plans and construction cost estimates; and completed basis-of-design documents and the military construction (MILCON) checklist. Design activities were conducted in accordance with 15% MILCON requirements, and we will soon develop the design-build RFP.

Construction Services

With a completed master plan and solidified design, critical facility improvements can happen safely and efficiently, even under the most scrutinized conditions. For all federal projects, we provide technical support during acquisition and construction, construction management and construction contract administration. We are experienced in reviewing construction contractor’s schedules for work progress, responding to RFIs and design change notices, supporting equipment and materials procurement, reviewing submittals, and assisting site representatives in resolving conflicts associated with the construction contract.

Case Study: Comprehensive Title III and Commissioning Services for Pantex Projects

Burns & McDonnell is currently performing construction services (Title III) for 12 tasks at the Pantex plant, ranging from small system replacement projects in a facility to large capital line-item projects. Each task includes review of construction submittals for compliance with the contract requirements, assisting with RFIs and contractor-requested design changes called installation change requests (ICR). Some construction service tasks include review and approval of as-built drawings. In these cases, our teams visit the job site with the contractor’s redlines to review them against the actual conditions and completed RFIs, ICRs and approved submittals.

Based on the field review, we determine if the contractor redlines adequately capture the final conditions. If so, we incorporate those changes into the documents for Consolidated Nuclear Security’s (CNS) records or to supplement configuration management drawings. We have developed a database used to track the status of each submittal, RFI or ICR, supporting both our internal team and providing up-to-date information for the CNS team.

For the Building 12-37 data center secondary electrical feeder project, our in-house commissioning engineers are supporting the construction contractor’s commissioning and startup activities by providing test plans and oversight of the process to validate that the installed equipment is ready for operation and meets design requirements. As it does for other large and complex projects, our CNS team works with the engineering and project management team to support the construction acquisition process by responding to bidder inquiries and providing updates to the bid documents based on requested changes. We also conduct field walkdowns, as needed, to help monitor construction progress in a timely manner.

The Burns & McDonnell Difference

Integrated Project Execution From Planning Through Construction: Ranked in the top 10 of design-build firms in the U.S. by ENR, we have an extensive team within all disciplines who provide quality planning, design and construction services.

Proven DOE and Site-Specific Knowledge: Critical project sites can benefit from increased efficiency and seamless transitions by leveraging our national DOE experience and capabilities, having successfully delivered more than 2,200 projects across DOE sites since 2001.

Successful Critical Decisions: Gain confidence in scope, schedule, risk and cost-related decisions based on our deep knowledge in navigating the DOE Order 413.3B processes. We have delivered more than $2 billion in capital planning and design services for DOE project sites, from developing mission need documents to evaluating critical decision deliverables. Our work consistently results in DOE approval, with projects that meet or exceed Critical Decision-2 baselines.

Matt Germann

Project Manager

P: 816-492-2894

Greg Smith, PE

Project Manager

P: 509-237-7601

✖