Solution

For this project, The Consolidated Mutual Water Co. turned to us for residuals management study, design and engineer-procure-construct (EPC) services.

The treatment process of the existing plant has flocculation and lamella plate settlers followed by submerged membrane filtration. For this project, The Consolidated Mutual Water Co. turned to us for residuals management study, design and engineer-procure-construct (EPC) services. The treatment process of the existing plant has flocculation and lamella plate settlers followed by submerged membrane filtration.

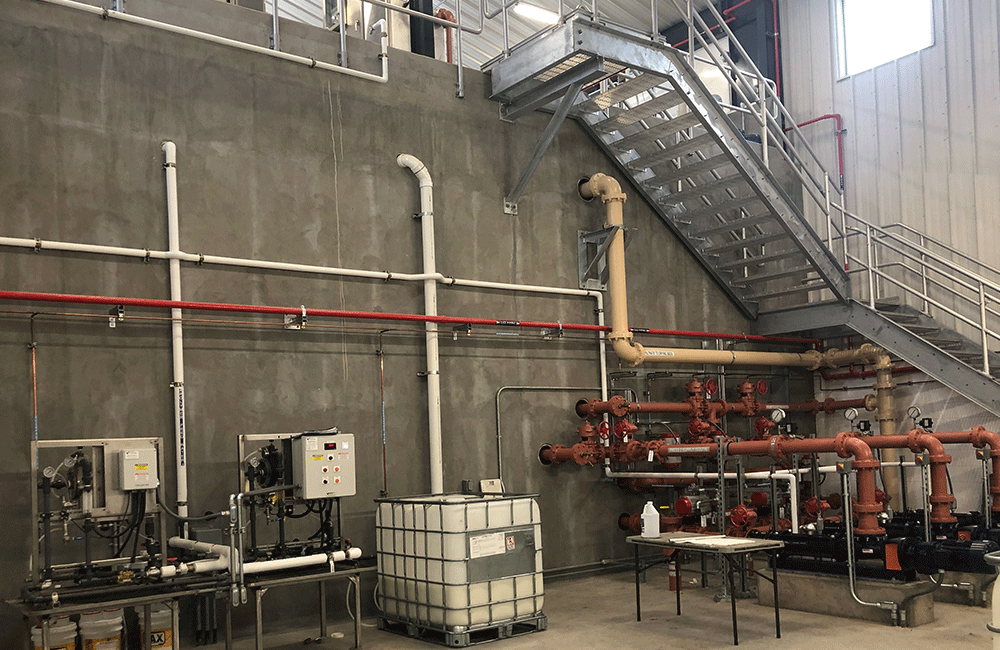

Upon completion of the analysis, we developed a detailed design for the new 4,400-square-foot building to house the new dewatering equipment. The new equipment includes two 15,000-gallon solids storage tanks, two dewatering presses, three cavity pumps, two polymer preparation systems, and feed valves, piping and controls.

Because the new facility would be located in the footprint of the existing drying beds, an interim residuals management plan was needed to keep the plant operating through the 2019 peak demand season. The EPC delivery method allowed for the procurement of the dewatering equipment during the design phase. This meant the equipment could be installed in a temporary enclosure and operated while the new facility was under construction.