Liquefaction Technology Selection

The liquefaction/refrigeration technology is a key element for an LNG project, and is often one of the first major decisions that is made as the project begins. Many factors go into selecting the type of liquefaction technology that fits the needs of the project, one of the main ones being the desired liquefaction capacity.

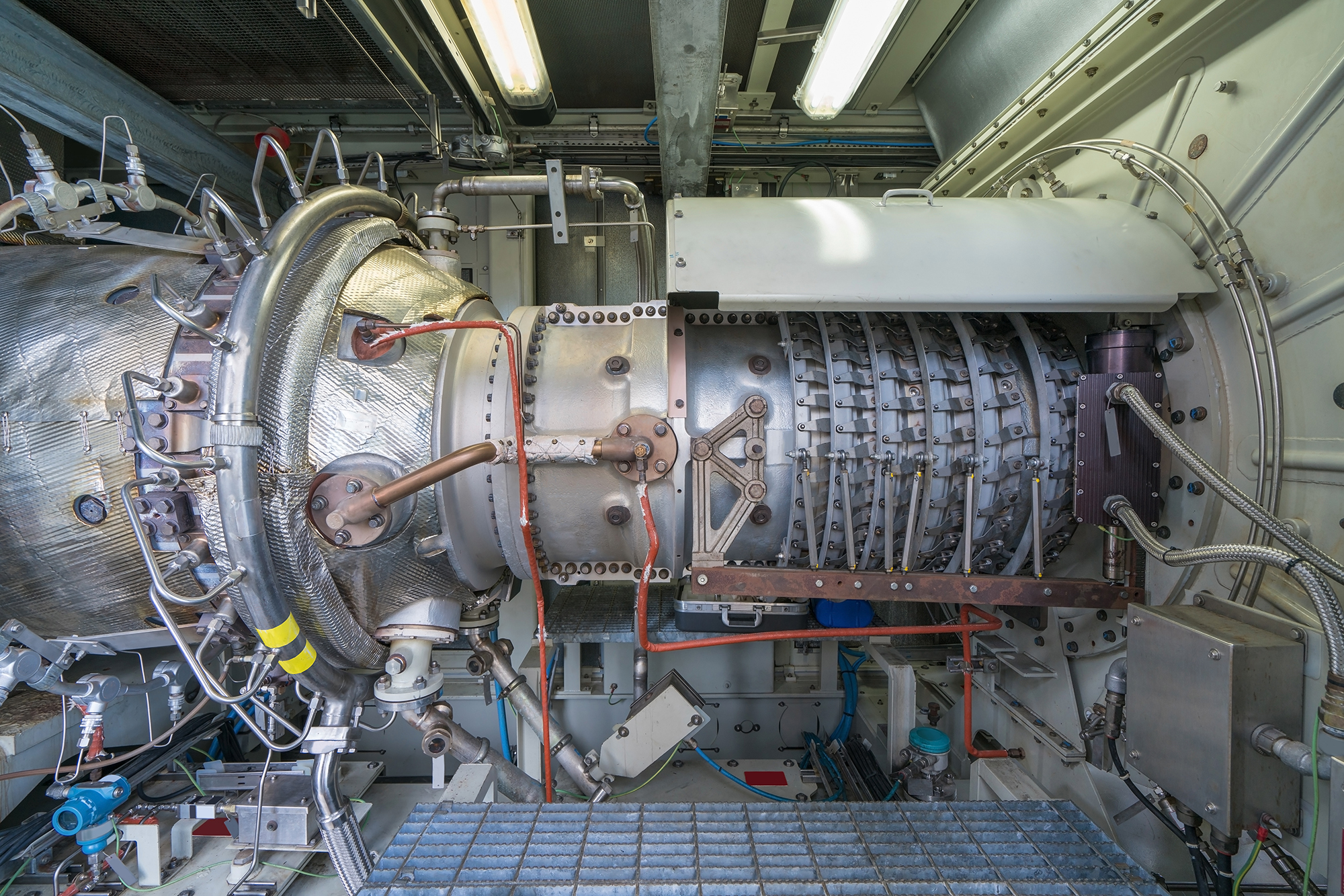

There are many different technologies and solutions available in the market. Some of the most well-known options are the nitrogen cycle, single mixed refrigerant (SMR), propane precooled mixed refrigerant (C3MR) and the optimized cascade process. Each of these technologies offers different benefits. For example, for a small peak-shaver facility producing around 0.05 million tons per annum (MTPA), the use of a nitrogen cycle may be the most beneficial. The nitrogen cycle offers the lowest efficiency of all the options, but it is the least complex and does not require a mix of multiple refrigerants for operation. Conversely, for a large liquefaction capacity, such as a baseload export facility producing 5-8 MTPA per liquefaction train, the C3MR or cascade processes would be a better option. These processes are more complex and require multiple compressors and multiple refrigerants, but they offer much higher operational process efficiency and lower capital costs on the basis of dollars per ton of LNG. At large production rates, efficiency becomes a major factor in minimizing operating expenses.

Other things that must be considered during the technology selection process are reliability, site-specific requirements and environmental considerations. A detailed evaluation of all the options can help in selecting the ideal configuration.