SOLUTION

St. Peters reached out to Burns & McDonnell for a filter evaluation. Together, the city and project team decided to employ simple tests to evaluate the water treatment process, as well as adopt a holistic approach to solving the city’s process issues.

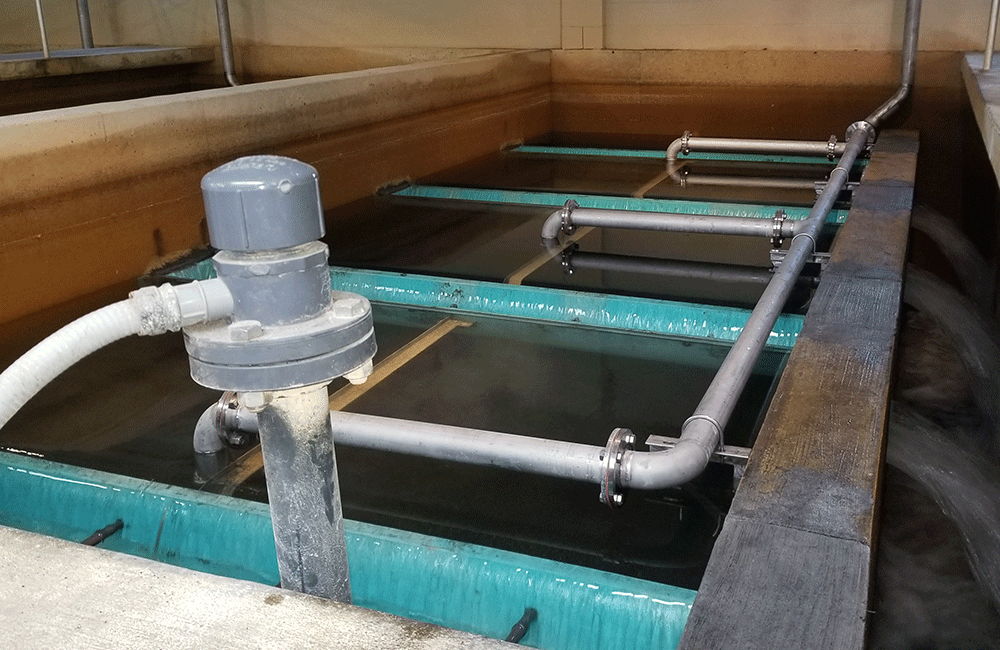

The study involved assessing the plant’s dual media sand filters, evaluating the lime carryover and identifying new lime equipment. When the filter evaluation was complete, the team collaborated on making recommended improvements for the plant. Improvements ranged from minor adjustments like recalibrating backwash flow rates to larger capital upgrades such as a new air scour system and filter media replacements. In addition, the team completed two separate bid packages in order to advance equipment items with long lead times and allow the city to use time-sensitive tax increment financing.

The team identified available manufacturers and equipment alternatives for the city. From collecting and evaluating vendor information, to conducting life-cycle cost analyses for equipment alternatives, the team provided valuable information to help St. Peters work toward implementation of the proposed improvements.