To untangle the conflict landscape, Burns & McDonnell was hired to lead a comprehensive resolution effort. In close collaboration with DLC and other key stakeholders, Burns & McDonnell initiated a multiphase effort focused on reducing the scope of DLC relocations through value engineering and strategic collaborative planning.

The team deployed a multiphase methodology that leveraged field data, stakeholder collaboration and engineering creativity. A critical component of the project centered on aligning diverse stakeholders’ needs. This process involved coordinating weekly working sessions that brought together Burns & McDonnell, DLC and PRT's engineer of record to collaboratively address and resolve project details in real time. The Burns & McDonnell project team brought in members from different departments that had experience with public improvement projects to provide additional perspectives on potential conflict resolution options and to help bridge communication and priorities among all interested parties. These working sessions significantly accelerated decision-making and helped navigate bureaucratic processes with greater efficiency.

Phase 1: Conflicts Reality Check

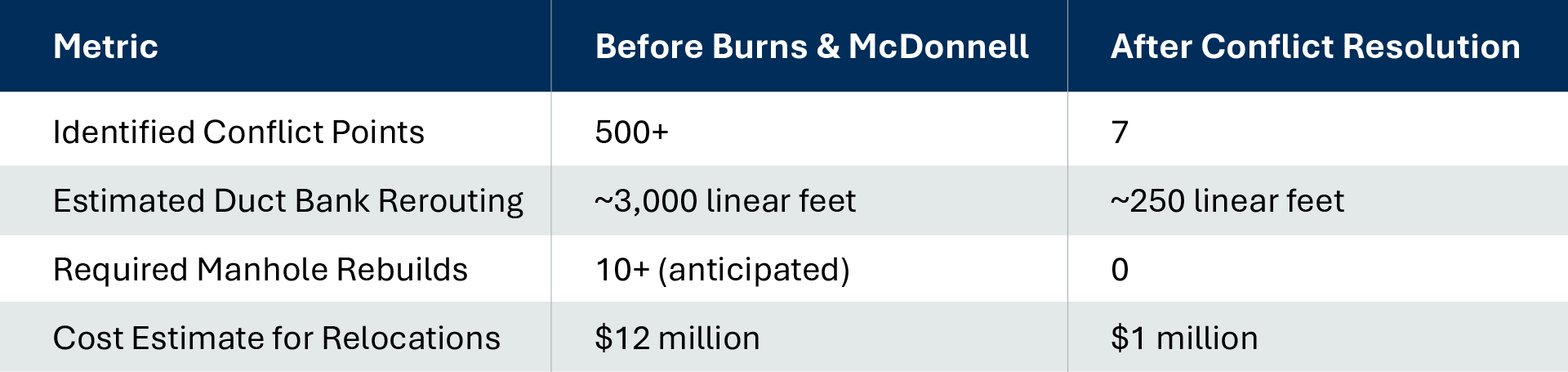

Burns & McDonnell began the project by launching desktop investigations into the more than 500 identified conflicts. These evaluations involved analyzing as-built drawings, manhole inspection reports, utility records and design plans to assess spatial relationships and to identify real areas of concern. By conducting these reviews, the project team proactively flagged conflicts that merited further field investigations to verify if they were true conflicts. Following this more in-depth desktop review stage, more than half of the identified conflicts turned out to be invalid false conflicts due to misalignments or assumptions based on outdated utility records, vertical clearance buffers, offset dimensions or legacy design assumptions that didn’t reflect real-world conditions. During this phase of the project, the team cataloged different types of false conflicts, including:

- Incorrect duct bank paths where the true location was not in close proximity to proposed facilities.

- Duct banks that appeared in conflict with proposed structures but actually were situated below proposed excavation extents.

- Duct banks that were already abandoned or scheduled to be abandoned as part of another project.

Phase 2: Field Investigations

With clearer data in hand, Burns & McDonnell advanced into field investigations. This phase focused on verifying the actual conditions underground and determining whether the conflicts were real. For conflicts that were legitimate, field investigations helped provide valuable insight into how the issues could be mitigated through design adjustments. Specifically, this phase involved performing detailed on-site investigations that identified the precise location, depth and condition of existing underground infrastructure.

The findings from this phase informed a more targeted and efficient approach to actual conflict resolution. During the field investigations, the team discovered that in many instances, what was seen on paper often didn’t match what was in the ground. A common technique used during this phase to confirm the location and condition of utility assets was hydrovac excavation — also known as soft digging — which uses pressurized water and a vacuum system to safely expose buried utilities without damaging them. Another crucial activity used to gather accurate, on-the-ground data, included utility identification and marking, in which technicians identified the type of utility infrastructure involved in the conflict and traced its path using electromagnetic locators or ground-penetrating radar (GPR).

These comprehensive activities helped capture field data that accurately reflected real-world conditions, enabling the conflict team to make informed decisions that would prevent service disruptions and significantly reduce unexpected issues and costs.

Phase 3: Conflict Resolution

This phase introduced full engineering support focused on resolving confirmed underground utility conflicts. This step was critical to maintaining uninterrupted and reliable service for utility users, as unresolved conflicts could result in service disruptions, safety hazards or expensive emergency repairs. Actual conflict resolution included:

- Relocating existing underground lines. This involved a multistep process: determining a new path that would not be in conflict with other proposed facilities, installing new duct banks, installing new cables through the new duct banks, disconnecting the existing lines, and then connecting the new lines and testing them before re-energizing.

- Developing custom foundations for proposed light pole locations. For conflicts between existing DLC duct banks and proposed light pole foundations, there was typically adequate space for an offset foundation that would include piers on either side of the existing duct bank. This allowed the existing duct bank to remain in place and the light pole to be installed in its originally planned location.

- Changing stormwater structure types. In some conflicts between proposed stormwater structures and existing DLC facilities, replacing the proposed inlet structure with another type of inlet structure was a viable solution.

- Conducting manhole roof replacements. Although no manhole structures required full reconstruction, several needed roof replacements to shift the manhole entrance out of the way of proposed curb lines or ADA ramps.

- Design workaround for challenging conflict. One particularly complex conflict involved a manhole that initially appeared to require relocation due to its interference with a proposed ADA ramp. The team explored multiple alternatives, including shifting the ramp, relocating the manhole lid and even constructing a new vault. However, each option was constrained by surrounding utilities and space limitations. Ultimately, the Burns & McDonnell team worked with PRT’s engineering team to adjust the ADA ramp geometry, which avoided modifications to the DLC manhole altogether — a low-cost, high-value solution.