SOLUTION

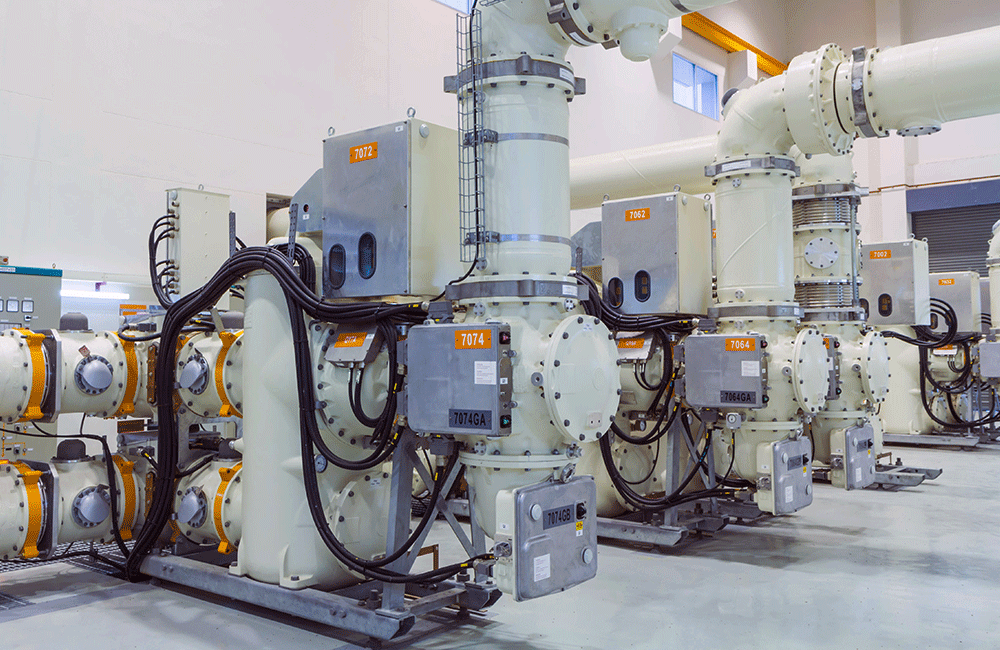

The reconfigured substation is designed for 115-kV operation in a breaker-and-a-half configuration, ultimately consisting of six bay positions. The facility currently consists of four fully populated bays and one partially populated bay in a breaker-and-a-half configuration, creating nine terminal positions. Five of the terminal positions are dedicated to 115-kV transmission lines, with two of the lines connected to overhead and the other three lines connected to the underground system. The other four terminal positions are dedicated to four transformers. The low side of each transformer remained as it was connected prior to the retrofit, serving the existing 13.8-kV yard. Relaying and control systems use IEC 61850 for most operations, including fully separated primary and backup systems located within a new control enclosure.

We started with developing safety and health plans by performing a systematic overview of the project’s scope with the owners, focusing on identifying potentially hazardous tasks, conditions, toxic/hazardous materials and special training or procedures that would be required to perform this project safely.

As the EPC prime contractor, we developed construction plans addressing off-site storage, laydown areas, stockpile areas and other construction logistics. Construction sequencing was carefully planned to accommodate critical project milestones and to balance the resource and construction space requirements.

To optimize the substation design, we worked closely with the owner, construction partners and a preferred GIS vendor to design and install:

- A six-bay breaker-and-a-half indoor GIS switchgear lineup, including independent bay positions for each of the existing lines and transformers.

- A data server to collect disturbance records, enabling engineers to monitor the health of assets across the system.

- An enhanced site layout that cleared 13,000 square feet of space for future site expansion.

- A gas density monitoring system to provide advanced warning of SF6 leaks and historical performance data, and to automatically generate SF6 gas inventory reports.

- Monopoles to transition overhead lines to GIS bushings.

- Protection and control systems based on IEC 61850 design protocols to improve local data archiving and retrieval of substation events, as well as enable secure, remote access for maintenance and troubleshooting.

- One of the first circuit breaker monitoring system applications in the U.S. to allow the client to prioritize and maintain circuit breakers before a fault or disruptive operation occurs.

Additionally, to keep the old facilities operational during construction and cut-overs to the new substation, we:

- Developed detailed cut-over and commissioning plans, as well as construction sequence documents illustrating each iteration of the process.

- Established multiple temporary three-terminal sources to feed the existing AIS substation and the new GIS substation.

- Followed a pragmatic approach to commission the GIS substation on a circuit‑by‑circuit basis.

- Conducted collaborative workshops with all project stakeholders to sequence construction and commissioning tasks safely and efficiently.