SOLUTION

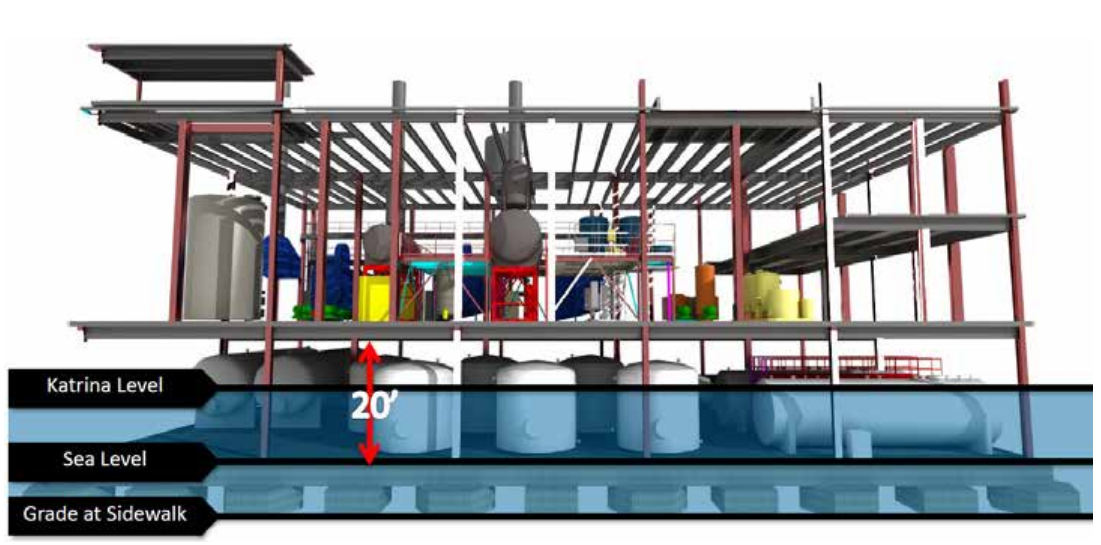

Enwave’s revised disaster preparedness requirements included redundant steam-generating equipment, increased plant storage capacity that would allow for seven days of fuel oil and process water storage. Required critical equipment had to be located 20 feet above sea level, which is equal to the highest natural elevation in the city. The solution was to install this equipment on the second floor of the facility, well above the Hurricane Katrina flood plain.

To satisfy these requirements meant precision and careful planning within the building’s tight urban footprint. Other equipment — emergency diesel generator and water softener salt silo — were moved to the roof, while self-priming pumps used to transfer water and fuel from storage tanks below the pump’s inlets were moved above the sea level requirement.

Variable-speed drives were used on most motors to maximize the steam plant’s overall efficiency, and feedwater stack economizers were selected to reduce gas consumption, with a heat-recovery heat exchanger to utilize boiler blowdown for pre-heating makeup water.

To help minimize effects of noise and movement during construction, a vibration monitoring program was used to make sure nearby residences, businesses and healthcare facilities were not affected by piledriving operations.