SOLUTION

We were retained by Ameren for more than the simple closure of 30 acres of two ash ponds at MEC. The project scope included reviewing current operational practices and developing a constructable and operable design in concern with diverse regulatory requirements, including the federal CCR rule, MDNR’s working regulations, and MEC’s National Pollutant Discharge Elimination System (NPDES) operating permit.

We also conducted a process water rerouting evaluation to identify the modifications necessary to accommodate ash pond closure, as well as specifying stormwater best management practices relating to maintaining and improving existing water quality during and after completion of construction.

Preparing CCR management, dewatering and stabilization specifications was another important aspect of the project. Saturated CCRs pose significant challenges due to their often unstable and unpredictable characteristics under dynamic construction loads. The design included performance-based specifications to facilitate safe and effective impoundment closure execution, including provisions for excavation, material handling, grading, subgrade stabilization, work sequencing and more.

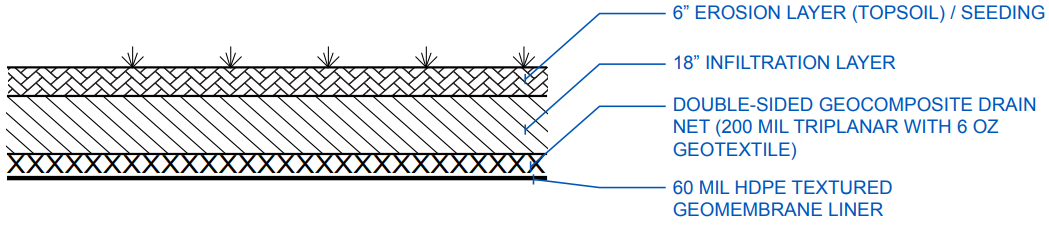

Finally, the project solution included evaluating, designing and bidding three alternative final cover systems. Two of the systems evaluated consisted of a synthetic turf cover system with a lower geomembrane component. The third alternative consisted of a composite 60-mil high density polyethylene (HDPE) flexible geomembrane material, a geocomposite drainage layer, a nominally compacted 18-inch infiltration soil layer and a 6-inch erosion layer capable of sustaining native plants.

.png?width=175&name=azco-white-logo-2020%20(1).png)