Carbon Capture, Utilization & Storage Solutions

As momentum grows to reduce carbon footprints, scalable solutions are key to meet decarbonization goals. Increasing requirements in both Canada and the U.S. are pushing for greater environmental standards. Ever-evolving incentives and legislation continue to drive change within the industry. These carbon capture, utilization and storage (CCUS) initiatives aim to encourage the reduction of greenhouse gas emissions for a more sustainable future.

Blog

What We’ve Learned From Louisiana’s Successful Primacy Application

Article

Decarbonizing Ammonia Production Begins With CCUS

White Paper

Carbon Capture Market Is Marching Forward

Load More

Identify Your CCUS Project Needs

Carbon Capture

CO2 Storage & Pipelines

Permitting Class VI Wells & Pipelines

Carbon Capture

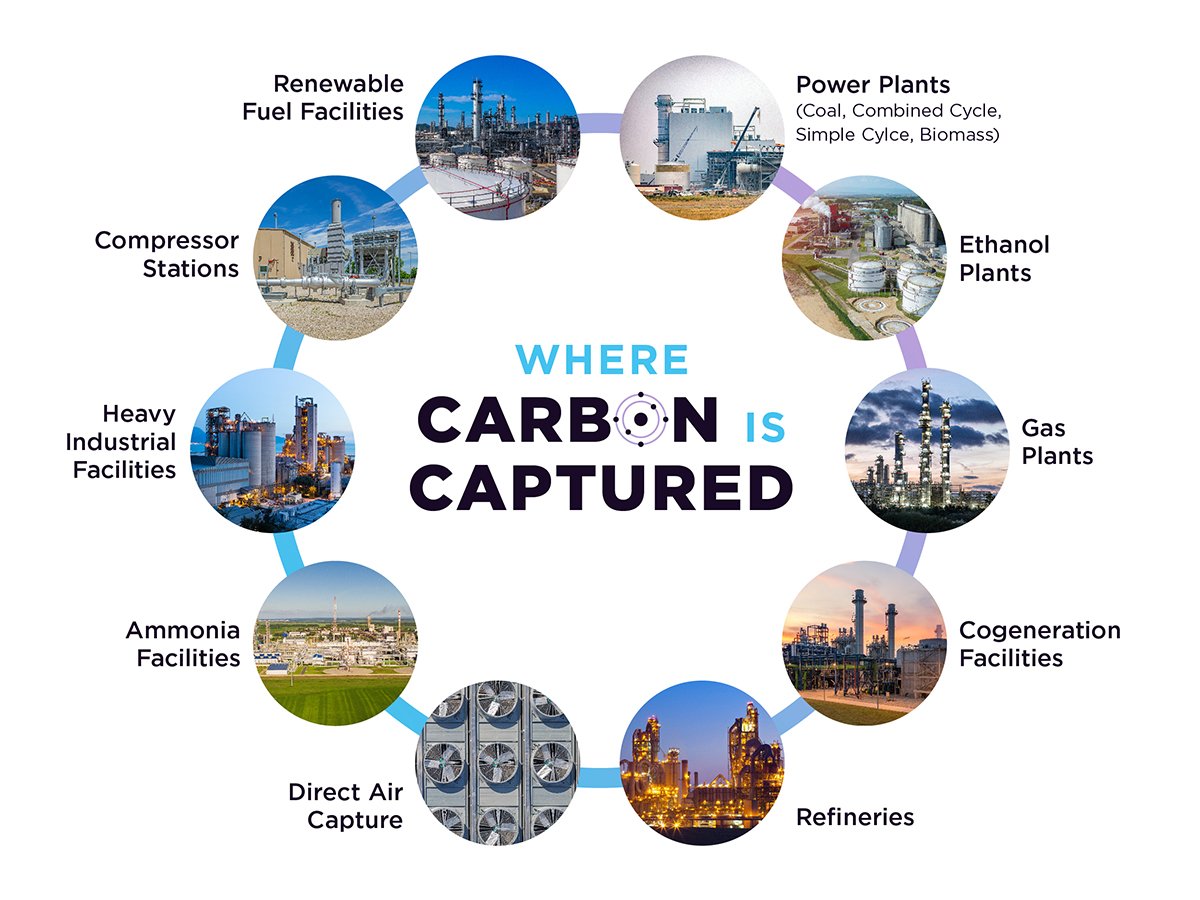

Understanding how to navigate commercial carbon capture technologies, cost and timeline considerations are essential for a successful project. Our extensive experience in the market allows us to understand point source capture, how to clean up gas and compression for use and storage. Whether looking to add carbon capture to your existing assets, or planning to build new units with carbon capture, we can guide you through the EPC journey and key considerations for a successful project.

Insights & News

Blog

Inflation Reduction Act Spurs Innovation in Oil, Gas and Chemicals Sector

White Paper

Carbon Capture System Design for Natural Gas Power Generation

White Paper

Power Surge: Preparing Electrical Infrastructure for Carbon Capture

Blog

Get Ready for a New Era of Carbon Capture at Power Plants

White Paper

Balancing Cost vs. Reward in Carbon Capture Streams

Blog

Cloning Design Provides Plug-and-Play Approach for Carbon Capture

Blog

Scrubbing CO2 From Ambient Air Through Direct Air Capture Technology

Article

Going Below Zero on the Path to a Lower-Carbon World

Blog

Q&A: Mark Heigold on Decarbonizing Canada's SAGD Operations

Load More

CO2 Storage & Pipelines

We understand certainty in results is imperative to your evolving business model to transport carbon and other alternative fuels. Upfront planning is crucial to determine optimal site locations and identify modifications to existing pipeline assets to put you on the right path for project certainty. Whether repurposing existing pipelines or building new CO2 pipelines to transport and store carbon, our team can guide you through flow assurance, capital and operating costs, along with health, safety and environmental factors for successful EPC project execution.

Insights & News

Blog

Building Pipelines for Carbon Sequestration Requires Long-Term Strategy

Blog

Unearthing the Potential of a Hub-and-Spoke Approach for CCUS

White Paper

Collaborative Land and Engineering Teams Help Balance Public and Owner Interests for Pipeline Projects

Load More

Permitting Class VI Wells & Pipelines

Permitting Class VI wells and pipelines is an often-lengthy process. Having the right team on your side — one with the experience necessary to navigate permitting complexities and put the optimal plan in place from the start — can make all the difference when it comes to completing crucial permits necessary for construction to mobilize. Correctly completing the process the first time helps to avoid costly schedule delays.

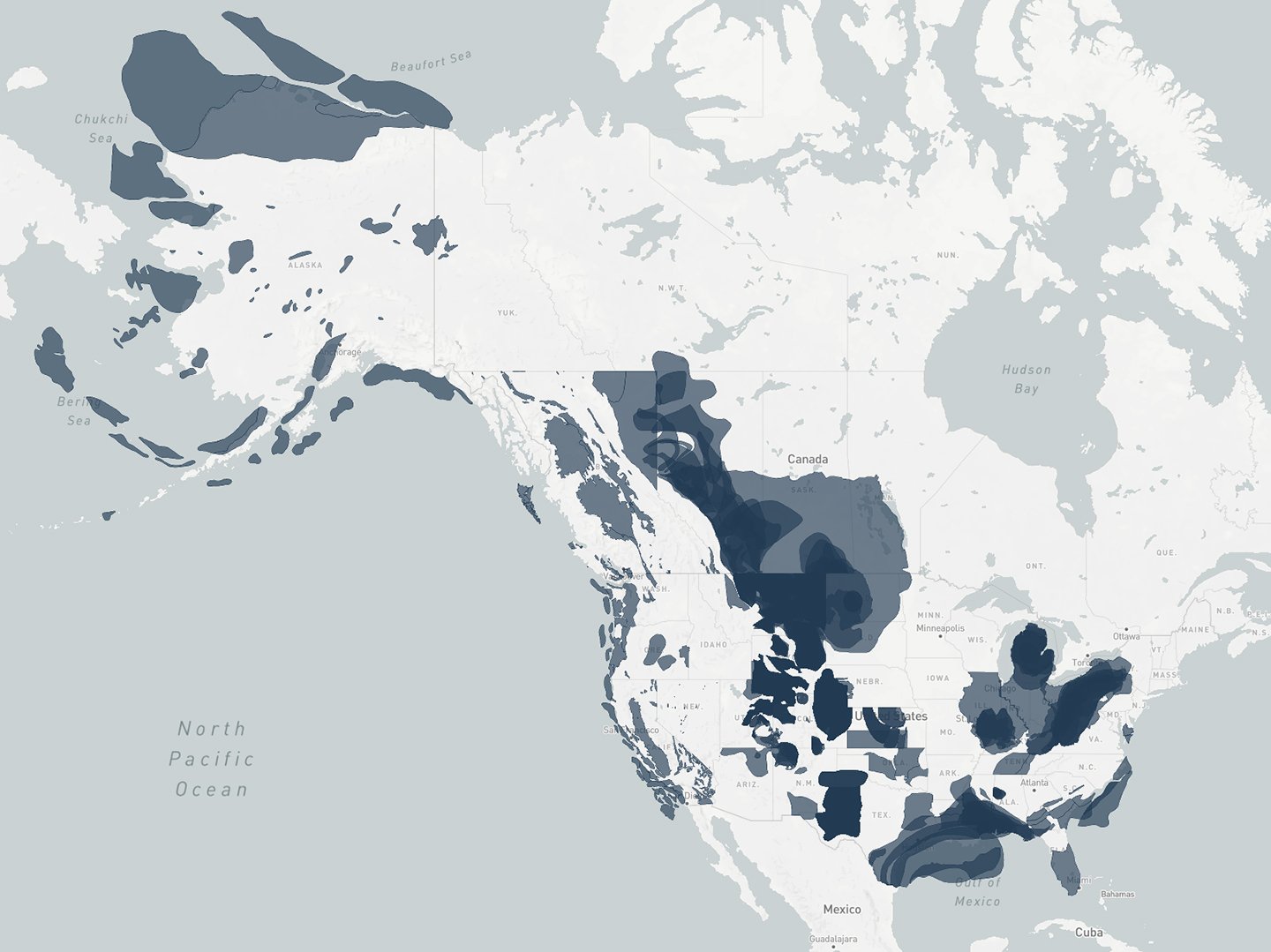

Optimal Sequestration Sites in North America

Footnote: There are a variety of options for carbon storage or sequestration, but the most common is injection into saline basins. These basins offer immense capacity throughout North America, with room theoretically to accommodate all U.S. and Canada CO2 emissions for the next several hundred years.

The Department of Energy's map, showcasing locations of CO2 storage projects.

Here is the link to the original source: https://edx.netl.doe.gov/geocube/#natcarbviewer

Insights & News

Blog

What We’ve Learned From Louisiana’s Successful Primacy Application

Article

Solid as a Rock: Streamlined Permitting Efforts Are Crucial for Carbon Storage Success

Blog

A Primer on ‘Primacy’ for Carbon Sequestration

Load More

Carbon Capture, Utilization & Storage Project Experience

Multisite Ethanol CO2 Capture

Class VI Injection Well Permitting for Midstream

Power Plant Carbon Capture & Storage for

Case Study

CO2 Pipeline Front-End Engineering Design

CO2 Recovery & Purification for Gas Processing Facilities

Direct Air Capture Hub for ClimeWorks

CO2 Recovery for Biofuels Production

CCS Geological Siting Study

Post-Combustion Carbon Capture for Natural Gas Compressor Stations

Multisite Cogeneration Carbon Capture

Load More

✖