Article

Preparing for the Unthinkable: PDX Fueling Facilities Apply Novel Design to Counter Extreme Seismic Events

BY Dan Eekhoff and Reid Unke

Creative solution for fueling facility design addresses rigorous new environmental standards to prevent fuel leaks.

In 1960, the unthinkable happened in Valdivia, Chile. A 9.5 magnitude earthquake — the most severe in recorded history — killed nearly 2,000 people, flattened buildings, destroyed roads and basic infrastructure, and triggered a massive tsunami that ultimately reached Japan, where dozens more perished.

In Portland, Oregon, local authorities are keeping history like that in mind due to recent studies showing the region is susceptible to a similar seismic event. Regulations have been implemented requiring improved earthquake resilience for fuel storage tanks located along the Columbia River — including jet fuel tanks serving the Portland International Airport (PDX).

PDX is Serial No. 1

For more than a decade the Oregon Department of Environmental Quality (DEQ) has considered new regulations that would require hardening of 17 fuel storage facilities located along sensitive waterways. One of those facilities is operated by the PDX Fuel Company, a jointly owned fueling consortium comprised of airlines serving PDX.

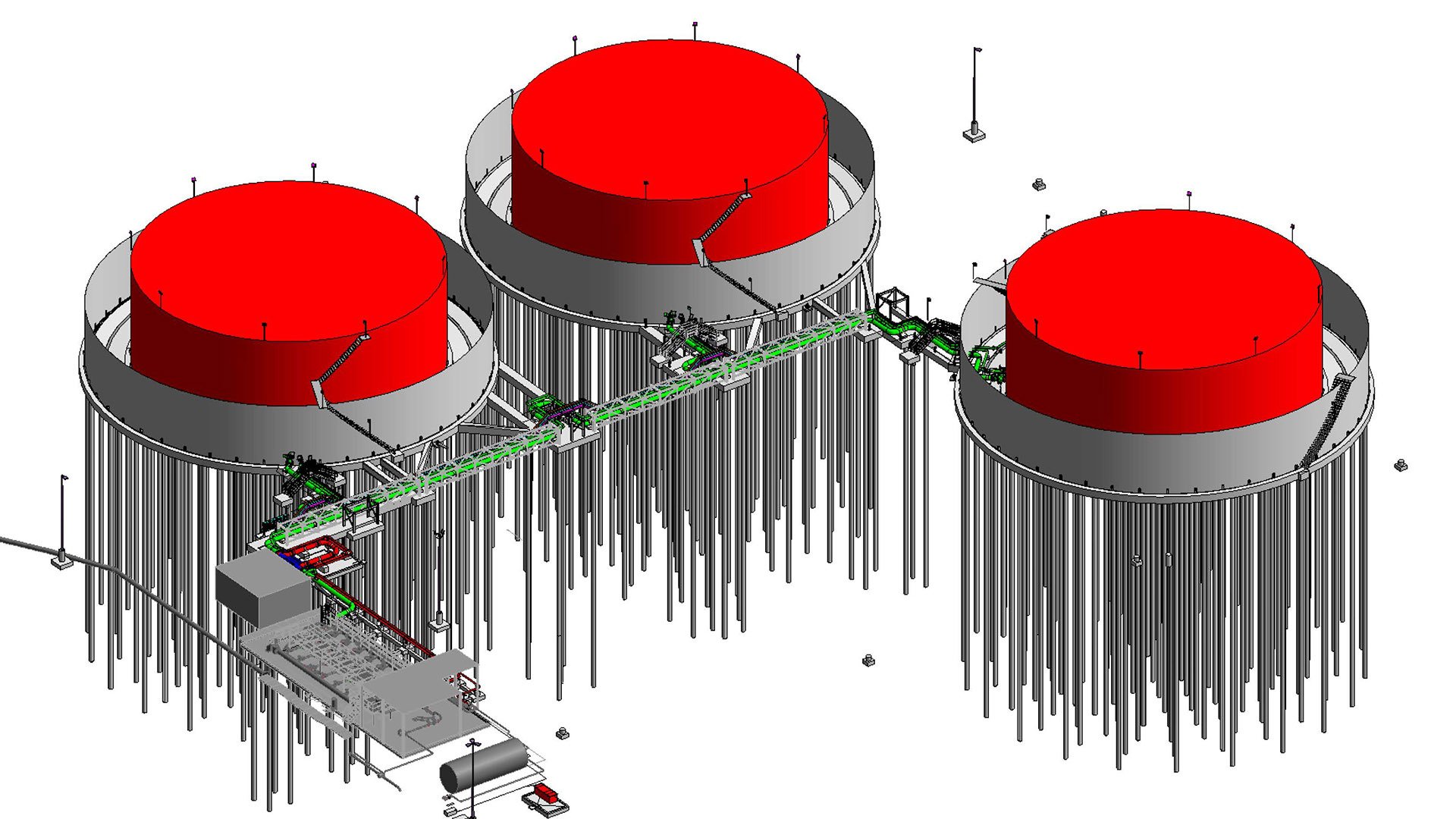

By the time the DEQ had coalesced around a rigorous new standard to prevent liquid fuel product leaks caused by extreme seismic events, PDX Fuel’s design for a new facility to replace the decades-old fueling infrastructure was already over 50% complete. The entire fueling facility — comprised of three tanks capable of holding over 7.5 million gallons of jet fuel (more than double the original storage capacity), along with the facilities pump station, control center, and other support systems — was slated for replacement.

The PDX Fuel design team went to great lengths to pivot the design to avoid spending money building brand new tanks that would immediately be required to be ripped out and replaced because they did not meet the new DEQ requirements.

The PDX Fuel Facility was the first (Serial No. 1) to tackle the new requirements — establishing novel design solutions and procedures that may become the model for the other 16 fuel facilities located along Oregon’s major waterway.

“Tank In a Bucket”

The design solutions needed for the revamped PDX Fuel Facility required an unprecedented level of creativity. Value engineering would have to stay within budget while also meeting newly introduced stability guidelines that had not been previously required.

Even with advanced knowledge new design requirements were coming, the specifics were not spelled out until final regulations were released. At this point, the PDX fuel design process was underway. As alternative solutions were considered by the design team, it became obvious that building conventional dikes to surround the fueling tanks would be prohibitively expensive. Under that approach, massive reinforced concrete walls would be needed, and those structures would have to be further stabilized by hundreds of piles drilled to over 130 feet below grade.

It was obvious a different solution was needed. An early alternative idea was to build a series of earthen dams that would eliminate the need for dike walls and deep piles. However, that quickly proved to be an unworkable solution due to the lack of available space for the tank system, and the cost of relocating all the other supporting fuel infrastructure.

Finally, one of the senior department leads, who has decades of experience with global fueling projects, suggested a unique solution, an idea that affectionately came to be called “tank in a bucket” by Scott Baker, the PDX Fuel Facility general manager. In response to the suggestion, the team began running calculations and cost estimates on the new concept. Not only would it work, but it would also save millions in containment construction costs.

By the end of the project there will still be nearly 500 piles driven deep into the ground to counter movement and related stresses on surface-level infrastructure. A local Portland area firm was engaged as a subconsultant to run extensive modeling of all design specifications before the final design would be approved by the DEQ.

Model for Future

A process that was akin to solving a Rubik’s cube now serves as a pathway that can be utilized by other fueling system facilities facing similar challenges.

The DEQ has extended its appreciation to both PDX Fuel and for the project design formulated by Burns & McDonnell. During a recent public hearing, one commissioner noted, “(Thanks) very much to PDX Fuel for actually getting on this so quickly and planning to complete it within four years (well ahead of the required schedule). Promptness rather than delay is a breath of fresh air.”

✖

READ Article

✖