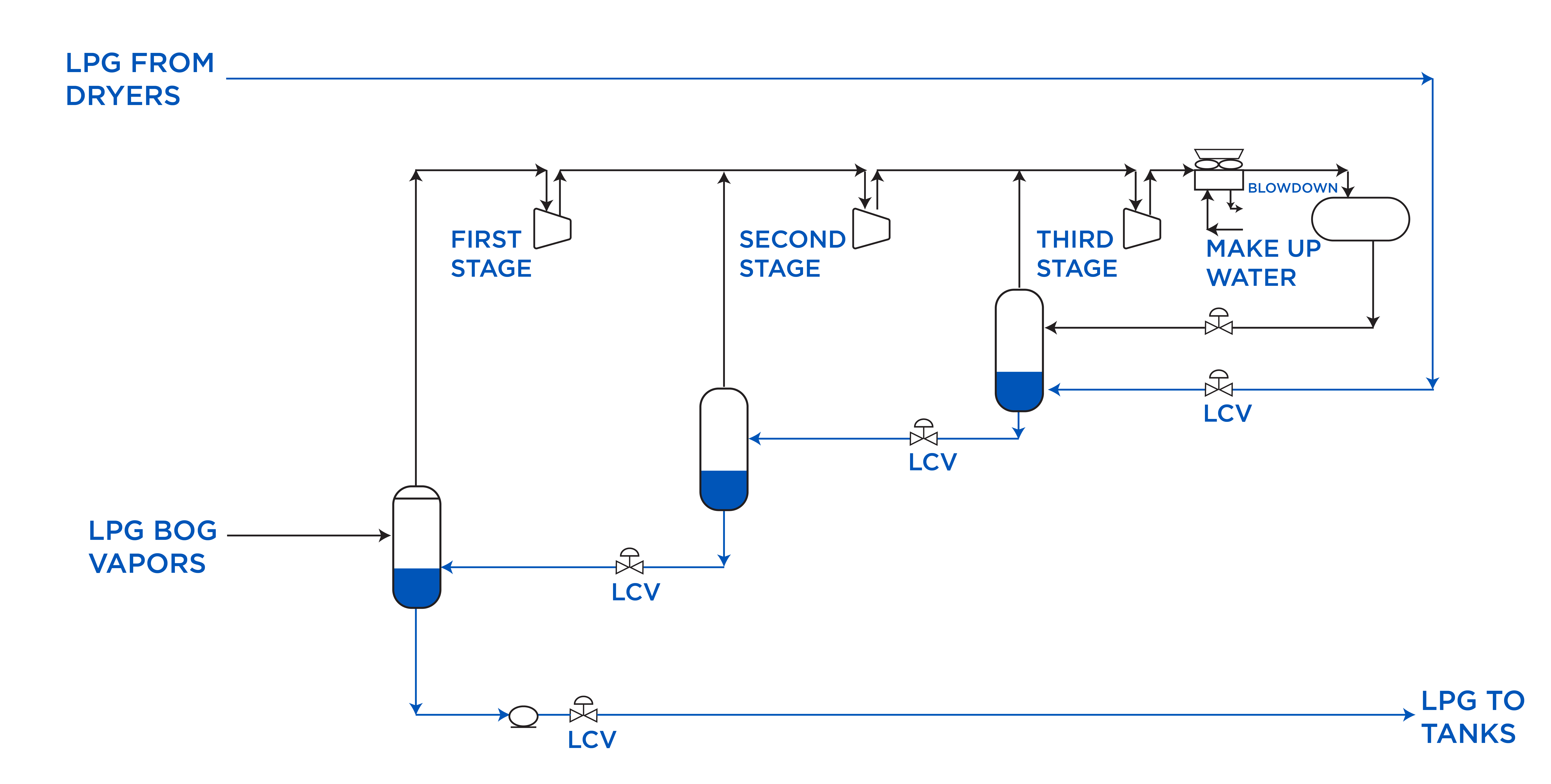

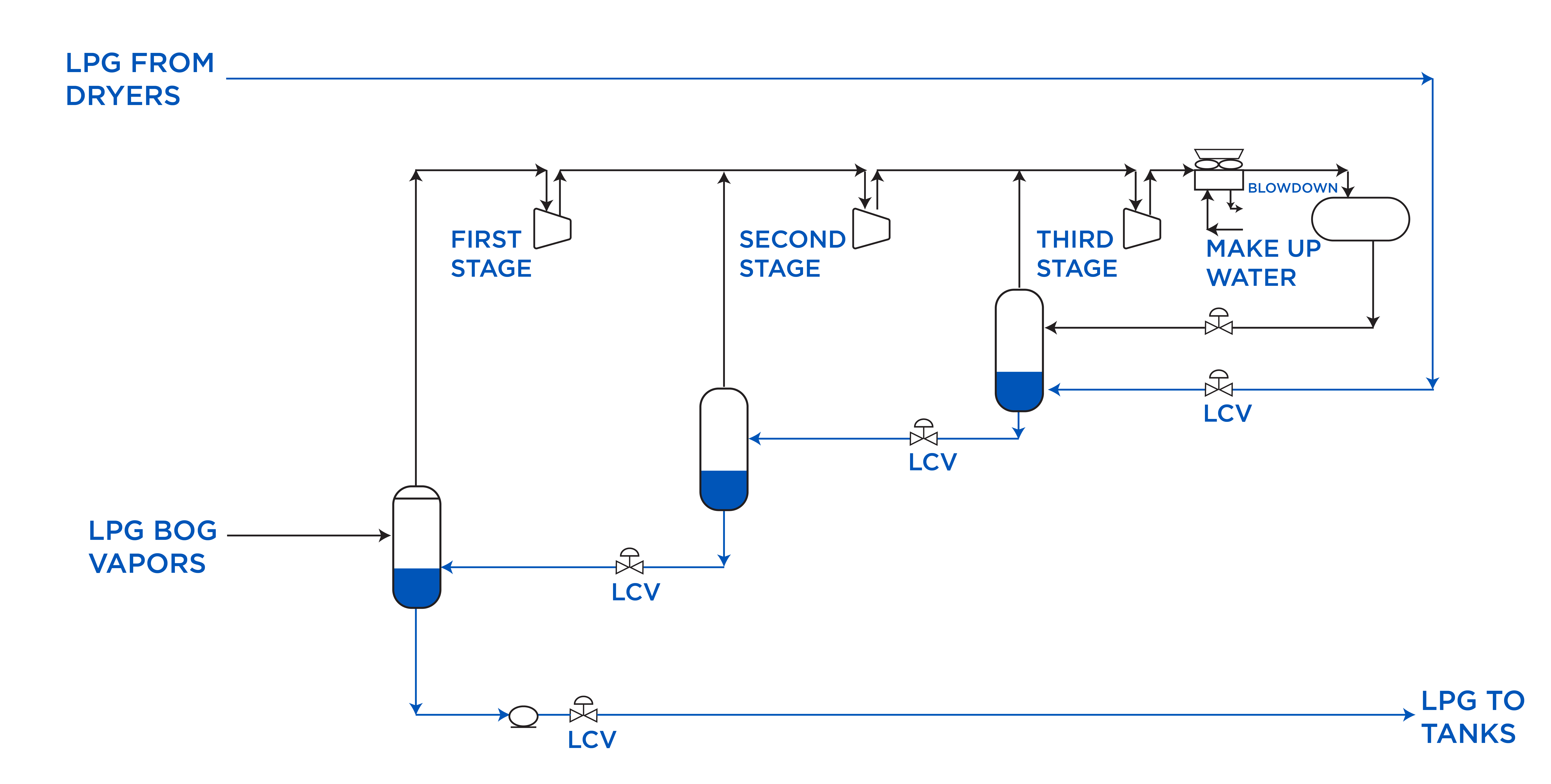

Figure 1: Open-loop refrigeration.

Article

Design Considerations to Optimize Export Terminals

BY Rohit Nankani, PE

Amid an increased demand for light hydrocarbons internationally, the United States has ample domestic supply because of increased natural gas production activities. There are several design considerations to evaluate for an export terminal once the business case has been identified, the site has been selected and export products have been determined.

An export terminal typically receives light hydrocarbon product from a pipeline at ambient temperature. The pipeline product has typically been treated to export quality and requires only dehydration before refrigeration. The product is dehydrated using temperature swing adsorption in desiccant beds. It is then refrigerated to its bubble point temperature at atmospheric pressure and loaded onto ships.

Refrigerated products can be stored in tanks before they are loaded onto ships. The technology selected for refrigeration will determine the initial capital expense, the number of pieces of equipment, the power required for refrigeration, and the overall operating expense.

The design capacity of the export terminal facility and projected onstream time are governed by the availability of storage for refrigerated products. Direct loading of refrigerated products to the ship is possible, but tanks provide more operational flexibility and higher load rates. The drawbacks of including refrigerated tanks in the design include capital cost, greater plot space and longer construction schedules. It is not unusual to initially commission a facility with the option of direct loading at reduced capacity until the tanks are built, then switch to tank storage.

Another item to consider in designing an export terminal is the type of tank. The options are single containment and full containment tanks:

The product being stored and insulation requirements typically govern the type of tank selected.

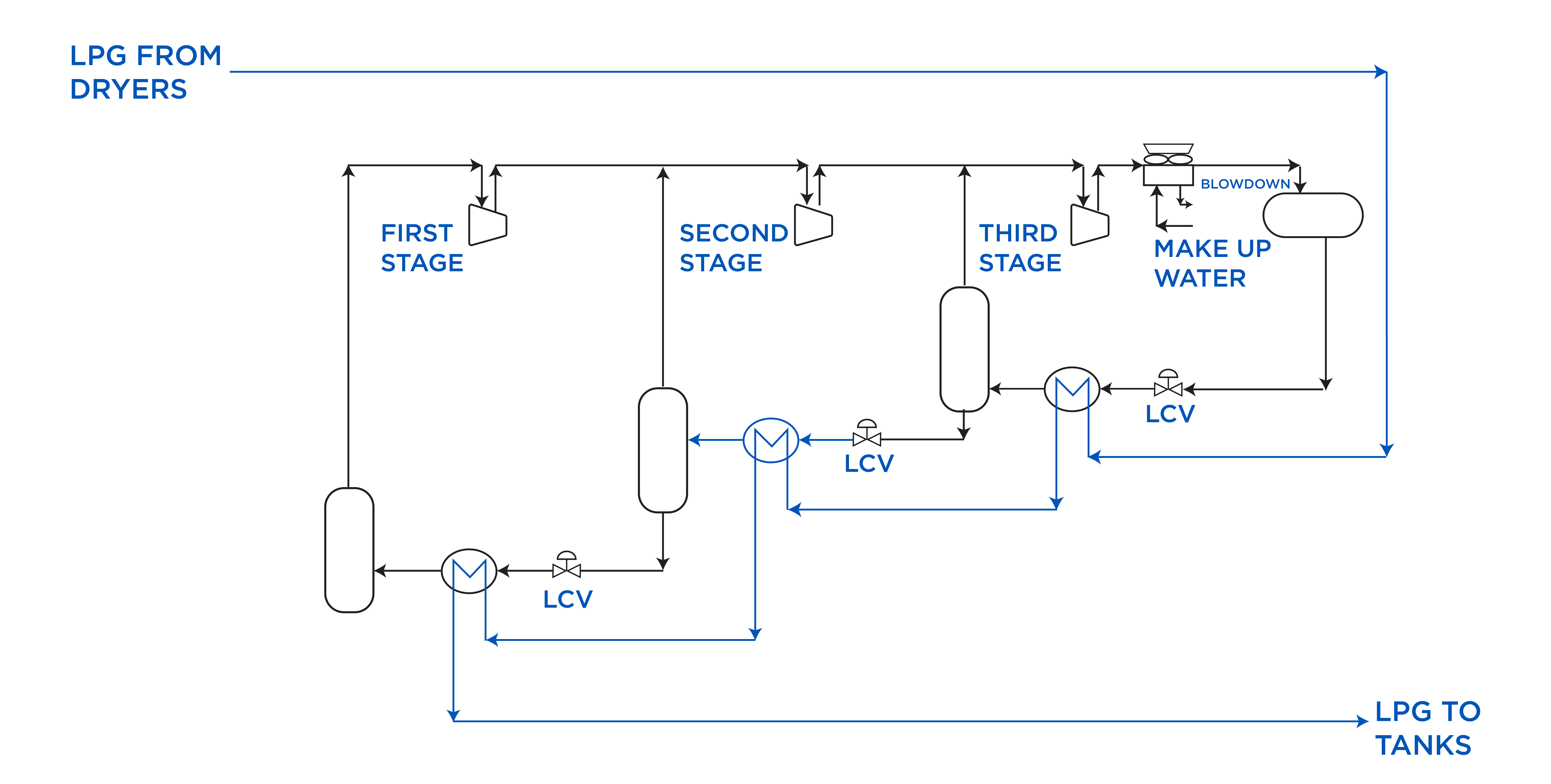

The most important consideration for the design of an export terminal is the selection of refrigeration technology. The options are closed-loop and open-loop refrigeration. For liquefied natural gas (LNG), closed-loop refrigeration typically is used because of the product’s refrigeration temperature. For propane, the controlling factor in determining the type of refrigeration design is based on product quality and the possibility of noncondensables. Closed-loop refrigeration systems are more flexible and provide advantages for handling light ends and contaminants; this design requires more equipment and higher operational expenses. In contrast, in an open-loop refrigeration system, the product itself is the cooling medium, so the system requires less equipment. Open-loop refrigeration technology requires less power and equipment but has less flexibility.

If more than one product will be refrigerated and loaded to ships at the terminal, then both open-loop and closed-loop technologies are feasible. The difference in refrigeration temperatures will determine both the design of the system and how the design can be integrated to optimize power consumption. The most common application for open-loop refrigeration technology is for combinations of propane and butane products. In this scenario, the propane product is used to chill the butane product.

The refrigerant compression system selected will vary based on the technology selected. Designers can either select large open art systems that leverage economies of scale or rely on multiple packaged refrigeration systems in parallel. Packaged systems simplify engineering and construction and provide inherent redundancy, but they also offer limited compressor selection and customization and will result in a larger number of individual equipment pieces. The selection of open- or closed-loop configuration often depends on owner preference or the presence or lack of noncondensables. The closed-loop option can be the most flexible, while the open-loop option will result in the lowest power consumption and least amount of equipment.

Figure 1: Open-loop refrigeration.

Figure 2: Closed-loop refrigeration.

Refrigerated tanks require management of boil-off gas (BOG). Design for BOG handling is based on the selected refrigeration technology. Several factors result in generation of BOG vapors, creating higher pressure in the tank:

For a closed-loop system, the vapors are compressed using a dedicated BOG system, which requires higher compressor horsepower. For an open-loop system, the gas is compressed only to the operating pressure of the open-loop compressor first-stage suction drum, thus requiring less compressor horsepower.

Another important element export terminals require is the availability of utility water. This is critical in the selection of condensers. If water is available, designers can install cooling water towers and use shell and tube exchangers for refrigeration condensers. This results in lower initial capital expenditures when compared to air coolers. The use of air coolers typically requires 15%-20% higher compressor horsepower and more plot area. The quality of water needs to be sufficient to avoid any biological growth and typically can be maintained by use of cooling tower chemicals.

The demand for refrigeration and export of lighter hydrocarbons from the United States is increasing and projected to double over the next four years. The selection of technologies for these operations is an art, and the choices are dependent on the physical properties of the hydrocarbons being exported. Working with an experienced partner — one that has worked on all phases from conceptual design to detailed design and construction — can help with selecting the optimal design for any application.

Cool Video Headline Goes Here

Video Column Complete

video description goes here. video description goes here

✖