Article

Choosing Between Simple Cycle and Combined Cycle Under New Emissions Standards

BY Danny Bush and Joey Mashek

The evolving regulatory landscape has presented power generation utilities with a complex choice as they consider large-scale gas generation projects and whether to build simple-cycle or combined-cycle power plants. With the U.S. Environmental Protection Agency's (EPA) updated New Source Performance Standards (NSPS) for greenhouse gas (GHG) emissions, decision-makers must carefully balance operational efficiency, financial feasibility and output needs, while maintaining regulatory compliance. While results of the recent election and new administration may lead to some uncertainty with NSPS, the rule is currently still in effect.

The EPA’s NSPS aim to reduce greenhouse gas emissions from new and modified gas turbine power plants. Originally set at 1,000 pounds of carbon dioxide (CO2) per megawatt-hour (MWh), the standard under 40 Code of Federal Regulations (CFR) 60 Subpart TTTTa is now 800 pounds per MWh, with a further reduction to 100 pounds per MWh beginning January 2032.

These new standards significantly influence the decision between simple-cycle and combined-cycle plants, as they dictate whether plants can operate as baseload units or must operate at a lower imposed capacity factor if the above limits cannot be met. Adding further complexity, the updated standard introduces the concept of intermediate load facilities, with a required limit of 1,170 pounds per MWh and a capacity factor limit of 40%.

Combined-Cycle Plants: High Efficiency, Higher Cost

Combined-cycle gas plants have traditionally been preferred as a baseload technology due to their higher efficiency. These plants utilize both a gas turbine and a steam turbine, significantly improving fuel efficiency compared to simple-cycle setups. While they are more expensive up front, their main advantage is generating more electricity from the same amount of fuel (which also results in a lower CO2 per MWh emissions rate).

However, complying with the upcoming limit of 100 pounds per MWh will require future baseload facilities to incur significant additional costs to mitigate carbon emissions, most likely through CCUS technology. CCUS technology also requires a large amount of auxiliary power, which would offset some of the traditional efficiency advantage of combined-cycle plants. For example, a 1x1 J-class combined-cycle plant with CCUS might generate roughly 750 megawatts (MW) of capacity with duct-firing but the auxiliary power requirements associated with CCUS might reduce the effective output to about 600 MW. While employing CCUS would allow the plant to continue operating as an unrestricted baseload facility, the economic impact of deploying carbon capture must be considered.

Alternately, utilities could forego the investment in CCUS and opt to build combined-cycle plants as intermediate load facilities, which then would be limited to a 40% capacity factor under the current rules. This decision would sacrifice a significant portion of the facilities’ potential energy production each year.

Simple-Cycle Plants: Flexibility at a Lower Cost With Trade-Offs

Simple-cycle gas plants offer different advantages and trade-offs. They are generally cheaper to build and operate, with a less complex design and lower initial investment. Simple cycle plants are often used for peaking power, making them an attractive option for utilities needing to respond quickly to fluctuating demand.

From an emissions perspective, modern J-Class combustion turbines can meet the 1,170 pounds per MWh limit on their own. Given their lower output and efficiency, utilities are unlikely to invest in CCUS technology behind simple-cycle engines, which would put them in the intermediate load category.

In the case of simple-cycle plants, decision-makers must evaluate the levelized cost of electricity over the life of the facility. Simple-cycle plants have lower up-front costs, but efficiency would still be less than that of combined-cycle plants (even with CCUS), leading to higher fuel expenses over time. Utilities need to weigh whether the reduced initial investment would offset potentially higher operational costs, especially with fluctuating fuel prices.

A Situational Decision: Balancing Needs and Constraints

The choice between simple-cycle and combined-cycle gas plants is situational, depending on several unique factors for each project. For utilities seeking higher efficiency and baseload power, combined-cycle plants with carbon capture may be ideal, despite higher up-front costs. Conversely, utilities prioritizing flexibility and lower initial costs may find simple-cycle plants more advantageous for covering peak demand. Capacity needs are critical to the decision, and under the current rules there are more options to consider than ever before.

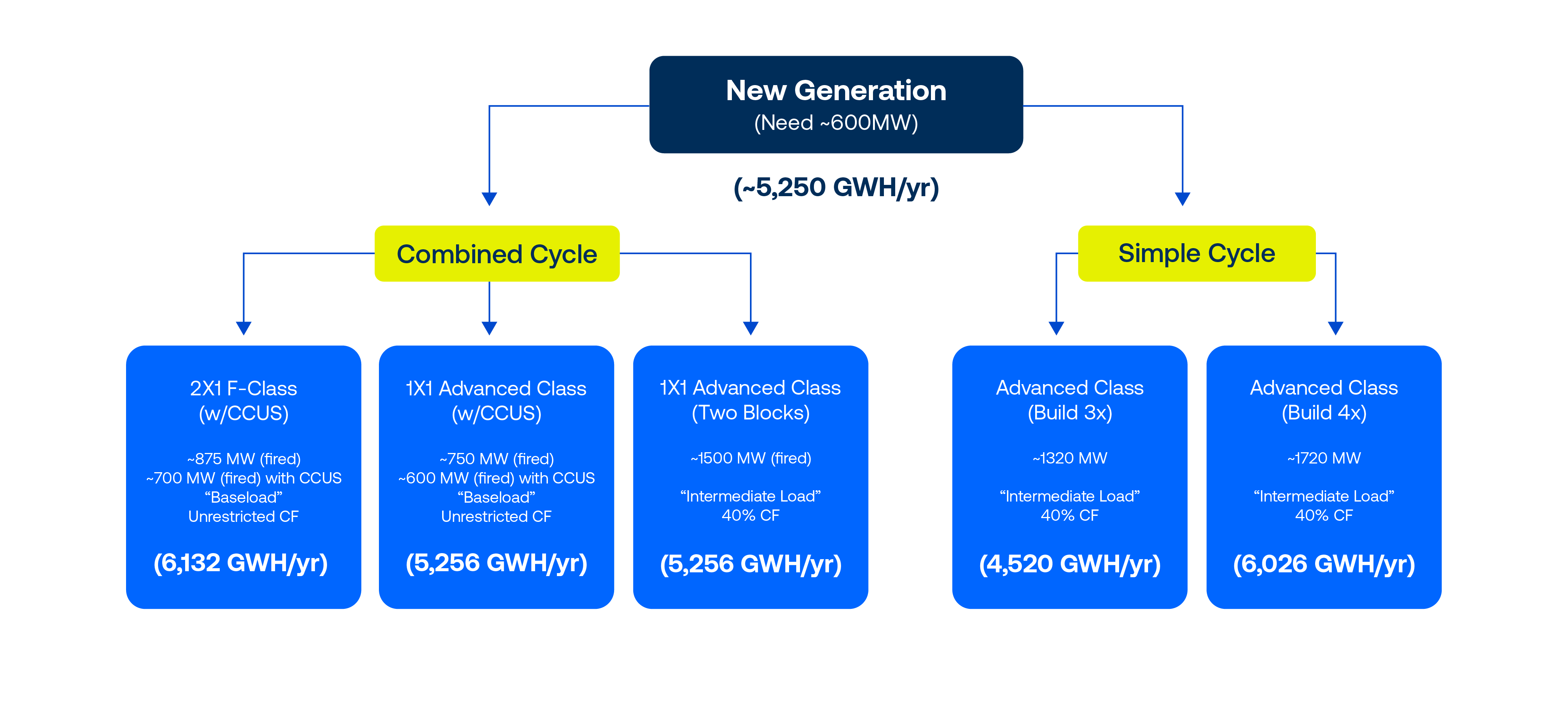

Graphic 1: Options for a hypothetical plant needing 600 megawatts of new generation.

As an example, if a utility needs approximately 600 megawatts (or 5,250 gigawatt-hours per year) of replacement generation, a combined-cycle setup could achieve this with fewer units and greater efficiency, while a simple-cycle approach would require multiple smaller units. The decision also depends on the utility’s anticipated emissions profile and willingness to invest in emissions-reducing technologies, like CCUS.

Additionally, utilities must consider other constraints, such as land availability, project timelines and financial resources, when making a decision. As lead times for acquiring equipment increase and regulatory pressures grow, it is essential to begin the decision-making process early and to thoroughly evaluate all variables.

Navigating Complex Choices

Unfortunately, there is not a clear choice between simple-cycle and combined-cycle gas plants under the updated NSPS. The decision depends on each utility’s specific needs, priorities and constraints. Combined-cycle plants offer higher efficiency and baseload capacity but come with significant costs, especially when incorporating carbon capture. Simple-cycle plants are more economical upfront but may struggle to meet future emissions standards.

Ultimately, utilities must balance efficiency, cost and compliance while staying attuned to regulatory changes. Engaging with peers, staying informed about technological advancements, and starting early are critical steps in successfully navigating these complex decisions.

Comparison Chart: Simple-Cycle vs. Combined-Cycle Gas Plants

|

Feature |

Combined-Cycle Gas Plants |

Simple-Cycle Gas Plants |

|

Efficiency |

Higher, uses both gas and steam turbines for improved fuel efficiency |

Lower, uses only gas turbines |

|

Capital costs |

Higher, due to complexity and additional equipment (e.g., carbon capture) |

Lower, with simpler design and fewer components |

|

Operational costs |

Higher, especially with carbon capture technology |

Lower up front, but higher fuel costs over time |

|

Capacity factor under 40 CFR 60 TTTTa |

Baseload operation would require GHG mitigation (such as CCUS)

Otherwise, intermediate load facility (40% capacity factor limit)

|

Intermediate load facility (40% capacity factor limit), assuming advanced class engine

|

|

Primary use (historically) |

Baseload power generation |

Peaking power generation |

|

Dispatchability |

Less flexible, due to baseload nature and bottoming cycle |

More flexible, ideal for fluctuating demand |

Cool Video Headline Goes Here

Video Column Complete

video description goes here. video description goes here

✖