In the quest to decarbonize their operations, a growing number of oil, gas and chemical facilities, including ethanol and ammonia processors, are seeking ways to capture and compress the carbon dioxide (CO2) emissions they generate for storage underground. The cost of these projects can be partially offset by tax credits authorized through the Inflation Reduction Act. Carbon capture, compression and storage equipment placed into service between now and Jan. 1, 2033, is eligible for tax credits of $60 to $85 per metric ton of captured CO2 for a period of up to 12 years, as detailed in Section 45Q of the U.S. tax code.

Of the many challenges involved in integrating a carbon capture process into an existing facility, one worthy of early attention is its impact on the supply and utilization of electric power. The motors needed to drive the compressors involved in carbon capture might outsize any currently operating at an industrial processing facility considering carbon capture. Compressors consume as much as 85% of the power used for carbon capture. On these projects, electrical infrastructure enhancements, including utility upgrades, could represent 20% to 25% of the overall cost.

Due to the remote locations of many heavy industrial operations, most carbon capture facilities are integrated with smaller, rural utilities that might not be equipped to meet the increased demand associated with carbon capture. By engaging these utilities early to identify necessary upgrades and seeking their input on key design elements — including voltage ratings, motor type and starting scheme — it is possible to identify ways to mitigate the risks associated with the added power demands.

In some cases, the high cost of utility upgrades could make a project financially unfeasible. The sooner the utility is engaged, the faster project feasibility becomes clear, enabling a firm to make a go/no-go decision before expending significant time and money on engineering. On projects that move forward, early engagement can beneficially impact the project’s scope, cost, schedule and operating performance.

Read The White Paper

In the quest to decarbonize their operations, a growing number of oil, gas and chemical facilities, including ethanol and ammonia processors, are seeking ways to capture and compress the carbon dioxide (CO2) emissions they generate for storage underground. The cost of these projects can be partially offset by tax credits authorized through the Inflation Reduction Act. Carbon capture, compression and storage equipment placed into service between now and Jan. 1, 2033, is eligible for tax credits of $60 to $85 per metric ton of captured CO2 for a period of up to 12 years, as detailed in Section 45Q of the U.S. tax code.

Of the many challenges involved in integrating a carbon capture process into an existing facility, one worthy of early attention is its impact on the supply and utilization of electric power. The motors needed to drive the compressors involved in carbon capture might outsize any currently operating at an industrial processing facility considering carbon capture. Compressors consume as much as 85% of the power used for carbon capture. On these projects, electrical infrastructure enhancements, including utility upgrades, could represent 20% to 25% of the overall cost.

Due to the remote locations of many heavy industrial operations, most carbon capture facilities are integrated with smaller, rural utilities that might not be equipped to meet the increased demand associated with carbon capture. By engaging these utilities early to identify necessary upgrades and seeking their input on key design elements — including voltage ratings, motor type and starting scheme — it is possible to identify ways to mitigate the risks associated with the added power demands.

In some cases, the high cost of utility upgrades could make a project financially unfeasible. The sooner the utility is engaged, the faster project feasibility becomes clear, enabling a firm to make a go/no-go decision before expending significant time and money on engineering. On projects that move forward, early engagement can beneficially impact the project’s scope, cost, schedule and operating performance.

Understanding Utility Constraints

With early utility engagement, a typical carbon capture and compression project takes two or more years to complete using an engineer-procure-construct (EPC) approach. Bringing a utility to the table later in the process can extend this timetable significantly. It can take months for a utility to plan and implement substation improvements or other needed upgrades — presuming it has the capabilities to do so. If not, those upgrades may be added to the ethanol, ammonia or other processing facility’s own scope of work.

Consider that the rural electric distribution systems that supply many processing facilities operate distribution-level substations ranging from 12.47-kV to 34.5-kV. These utilities often own the distribution system all the way into smaller facilities’ switchgear. Operating loads for these processing facilities are typically 10 megawatts (MW) or less, with some less than 5 MW.

The utility distribution substations feeding these facilities may also have relatively weak power systems because of their low short-circuit capability. This electrical infrastructure is insufficient to power the high-horsepower compressors, pumps and fans in carbon capture and compression projects. Utility upgrades may be necessary to provide the starting torque or starting power needed to start these compressors. While the power supply does not directly influence the performance of carbon capture processes, it must be reliable and adequate for the demand created by carbon capture equipment.

Early engagement with utilities can enable solutions to these challenges. Discussion topics can include everything from transmission line and substation capacity to feeder availability, voltage dip limits and power factor requirements, land acquisitions, partnerships and more. Conversations can prove fruitful as parties negotiate utility contracts based on power demand, energy consumption and service voltage for the new facility. These discussions can commence as soon as the industrial facility has identified its conceptual compressor size and motor data, two factors that are necessary to determine substation capacity requirements.

Motor Choice Matters

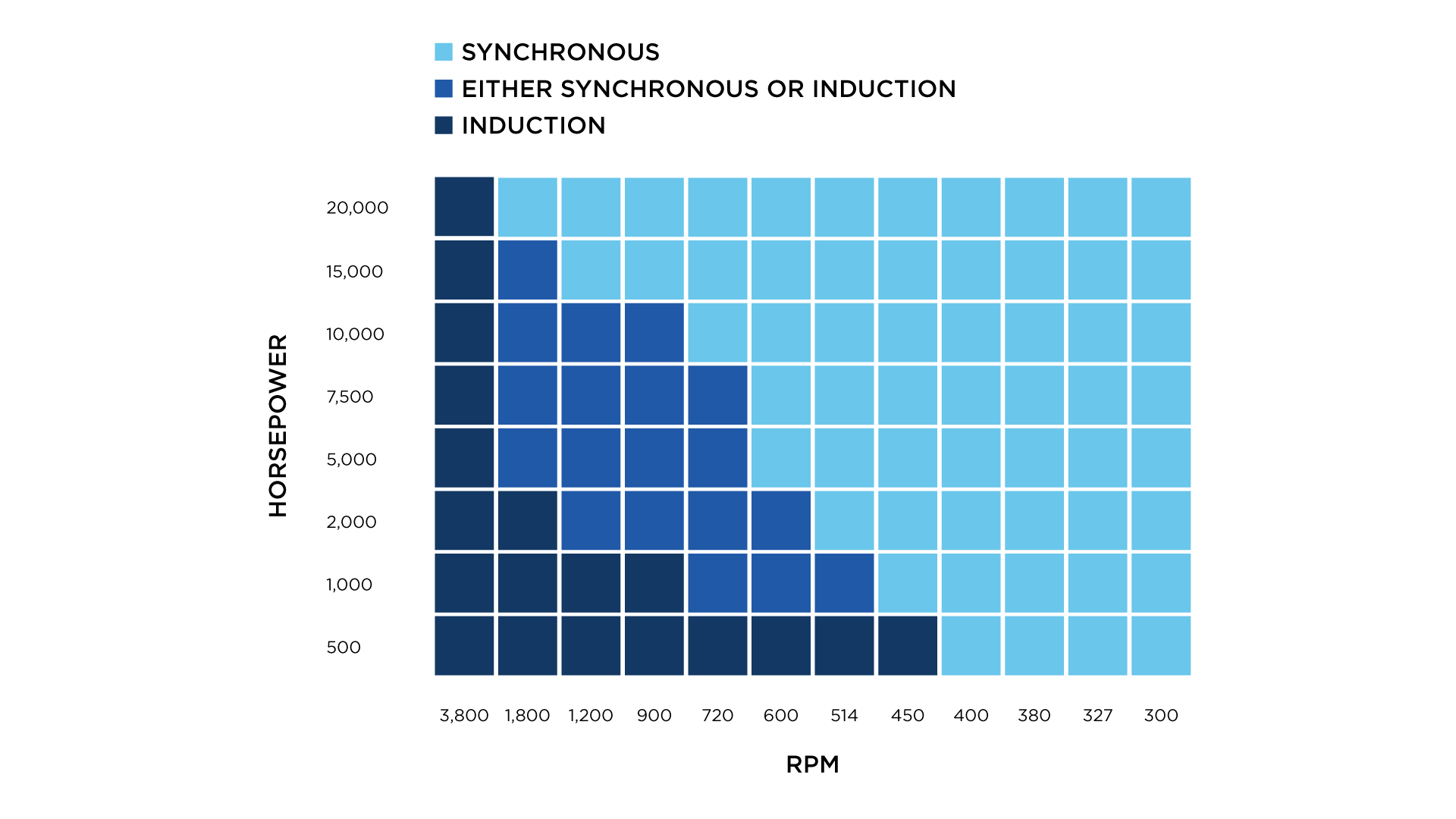

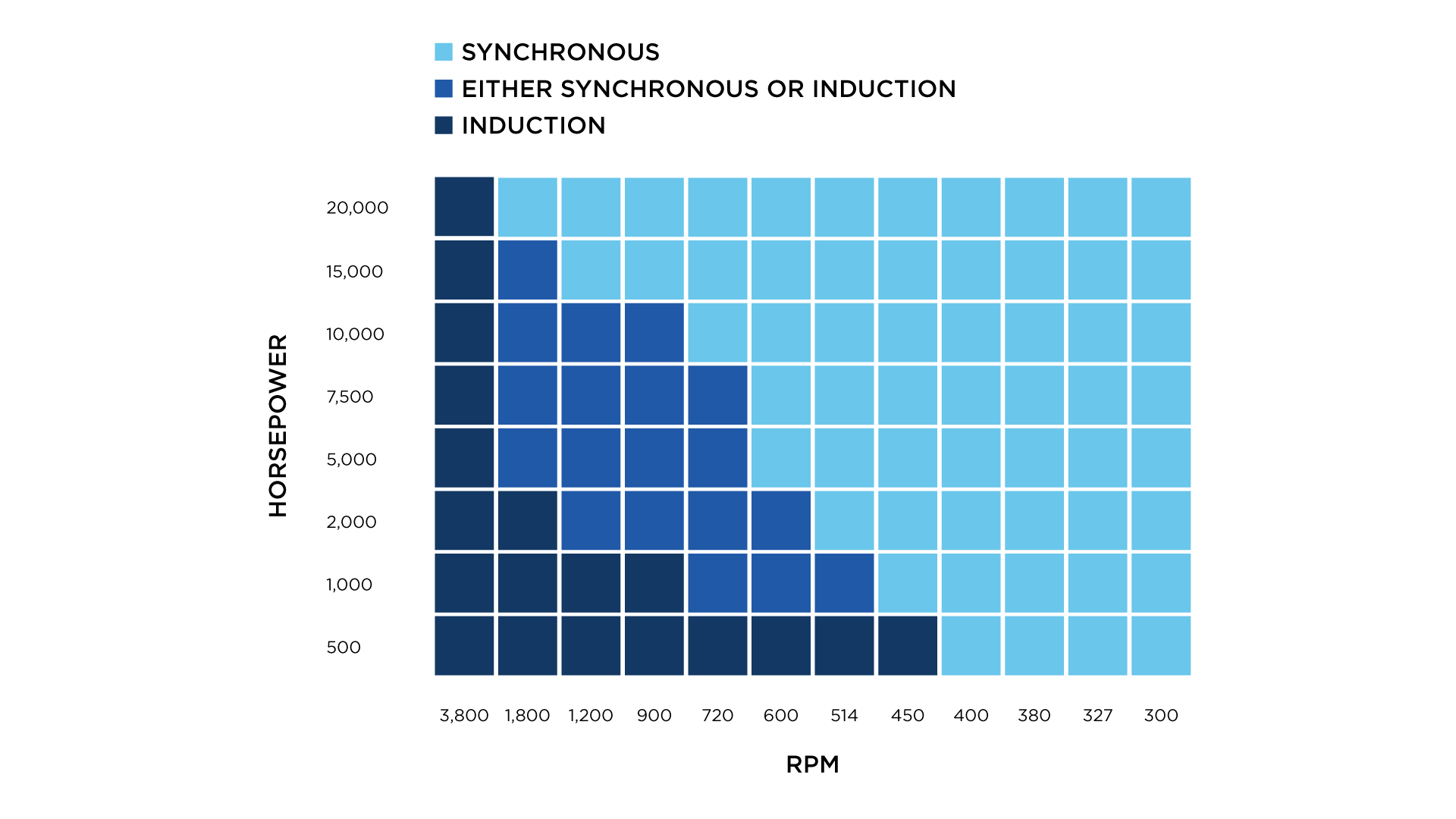

Utility input can also inform decision-making on a range of carbon capture design and equipment options, beginning with motor choice. For carbon capture applications requiring less than 15,000 horsepower, industrial processors frequently opt for induction motors because of their simplicity, reliability, ease of maintenance and compatibility.

Those with higher horsepower applications favor synchronous motors, which can deliver up to 60,000 horsepower with voltages of up to 13.8-kV. Synchronous motors tend to be used for low-speed reciprocating loads and for high-speed large horsepower loads, or to provide power factor correction. Both induction and synchronous motors can be paired with adjustable speed drives (ASDs).

Although their initial capital cost is higher, synchronous motors are more efficient than comparable induction motors. The incremental cost difference might be justified over the 25-year life typical for these motors (see Figure 1).

Figure 1: The choice of an induction or synchronous motor for carbon capture and compression, based on the horsepower and voltage requirements of the process it will drive. Source: WEG.

CLICK TO ENLARGE

Choosing Motor Starters and ASDs

Even with substation upgrades, utilities still may not have the resilience to endure the stresses present and supply the torque needed to start the giant compressors used in carbon capture. These compressors may be driven by motors larger than any found in existing natural gas, ethanol, ammonia and other processing facilities. To produce the torque and horsepower output needed to start them under loaded conditions —three to five times the amount needed for normal operation under load — these motors require exceptionally high starting torque.

To mitigate any constraints on its ability to deliver this level of torque, a utility might require a facility to adjust the startup process by installing a soft starter and/or ASD to the compressor. A soft starter makes it possible to ramp up the compressor motor gradually during startup, reducing the stress on the electrical system. An ASD controls the motor’s speed and torque by varying the frequency and voltage of the power supply. ASDs optimize motor performance by adjusting the motor’s speed based on load requirements, with more sophisticated, active-based models using real-time data to provide precise control over motor speed and torque.

It should be noted that the electronics and drives used for large compressor motors may differ from those already used in ethanol plants and some other facilities. Motor, soft starter and ASD selection therefore requires critical attention, with final decisions hinging on the local utility’s capabilities, as well as motor acceleration time, starting torque, voltage drop at startup, power factor and other technical considerations. The utility’s participation in these discussions is invaluable.

Voltage Selection

Voltage selection also plays a central role in a successful carbon capture process. The choice of voltage depends on factors such as equipment power requirements, distance of power transmission, safety considerations, regulatory requirements and overall system efficiency.

Voltage selection impacts the cost of — and, in some cases, the need for — utility transformers, associated motor feeders, switchgear, ASDs and other accessories. Power distribution system optimization is driven by voltage architecture, which determines everything from the size of the power distribution center’s footprint to maintenance costs and system efficiency (see Figure 2).

|

CONSIDERATIONS

|

VOLTAGE OPTIONS

|

|

|

13.2-kV

|

6.6-kV

|

4.16-kV

|

|

Overall cost

|

High

|

Medium

|

Low

|

|

Switchgear cost

|

High

|

Medium

|

Low

|

|

Voltage drop issues

|

Lower risk

|

Medium risk

|

Higher risk

|

|

Need for utility transformer

|

Low

|

Medium; choice impacts overall efficiency

|

Higher; choice impacts overall efficiency

|

|

Motor frame size

|

Largest

|

Mid-range

|

Smallest

|

|

Power distribution center footprint with ASD

|

Largest

|

Mid-range

|

Smallest

|

Figure 2: Voltage choice can impact everything from the power distribution center footprint to cable and switchgear costs.

Power Distribution Center Considerations

In the oil and gas industry, the power distribution center (PDC) for a carbon capture and compression system is typically prefabricated off-site in a controlled environment and delivered with the equipment already installed. Due to long lead times for some electrical equipment, the PDC can be a critical path item on most carbon capture projects. Projects benefit when the PDC’s design features are specified early, given that they may define the plot plan; establish interface conditions between the utility and the process; and satisfy an ethanol, ammonia or other processing facility’s electrical distribution needs.

Other high-priority issues include:

- PDC location. Overall project costs can be reduced when the PDC location is optimized within facility borders, thereby minimizing duct bank length, cable trays, pipe rack width and voltage drop. When a higher-voltage ASD is used for startup of large compressor loads, the PDC is more likely to be located near the load.

- Heating, ventilation and air conditioning (HVAC). Because ASDs emit a significant amount of heat, they require larger HVAC systems. When designed to include an economizer, these systems can repurpose the heat generated by ASDs to heat the PDC building or other facilities during cool months, reducing the HVAC load and improving overall energy efficiency.

- Route study. The options for transporting a PDC to a remote ethanol, ammonia or other processing facility can be limited because of weight limits and maximum dimensions for the loads. Route studies may be needed to identify roads that can accommodate the prefabricated PDCs.

Reaping the Benefits of a Cloned Design

Industrial processors that standardize their processes need only design a carbon capture system once. Using a plug-and-play approach to process technology and equipment selection, it is possible to create modular designs that can be cloned and adapted to numerous sites.

Because this approach standardizes the PDC’s design and layout, transformer locations, and other design elements, it also saves time, creates economies of scale, and reduces capital and operating expenses. Communication with utilities can also be jump-started with standardized designs, which provide much of the information parties need to make early, well-founded decisions on utility upgrades and the interface between the local power supply and the carbon capture and compression process.

While as much as 90% of design elements can be cloned from one site to the next, a small percentage might require customization to accommodate utility agreements, soil differences and substation configurations, among other local factors. For example, a facility’s electrical distribution equipment requirements may be affected by voltage supply availability. Similarly, ambient temperature differentials can affect heat trace requirements and cable tray design. Electrical distribution equipment, grounding design and utility substation configuration are among other design elements that might need to be adapted to local needs.

The Bottom Line: Being Proactive Pays

Integrating carbon capture into an existing operation presents many challenges related to the supply and utilization of electric power. But these are not the only challenges. The water supply and other systems can be impacted as well. Because the infrastructure required for this process is substantial, it is advisable to begin planning much earlier than what might be typical on other projects. Early coordination with utilities and careful consideration of key design components can prevent lengthy delays and yield millions of dollars in savings.

In sum, a proactive approach is fundamental to carbon capture project success.